- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Reimagine Enterprise Asset Management Business in ...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member44

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-02-2018

5:57 AM

If individually we subscribe to the belief that we can always do things in a better way tomorrow and translate these belief into tangible actions, we are on the highway of sustainable improvement. Such employee efforts aligned to the organization’s strategy, can sustain business endeavors to reinvent and reimagine its model.

In this era of digital business transformation, what is Next to what we are currently doing? This as a constant thought process is a business imperative. It is important every management is well versed in digital technologies and have clear plans to reimagine their business models. Boundaries between the physical world, people and internet will increasingly be blurred when organizations adopt more of fourth industrial revolution (Industrie 4.0) in their existing business process.

What is Next to what we are currently doing in Equipment Asset Management world? Let us have a sneak peek. Equipment Asset operation and maintenance are typically confronted with the following business challenges:

Applying digital innovation to unlocking Enterprise Asset Management (EAM) business opportunities are very much possible with a fresh approach, called, Next practices in EAM processes driven by the Intelligent Enterprise.

Intelligent Technologies like SAP Leonardo – Connected Assets, IOT – Predictive Maintenance, Machine Learning / AI will support proactive maintenance planning vis a vis traditional approach of reactive and preventive maintenance. Equipment as a service (EAAS) offerings will effectively offset challenges of obsolescence and skilled resources constraint.

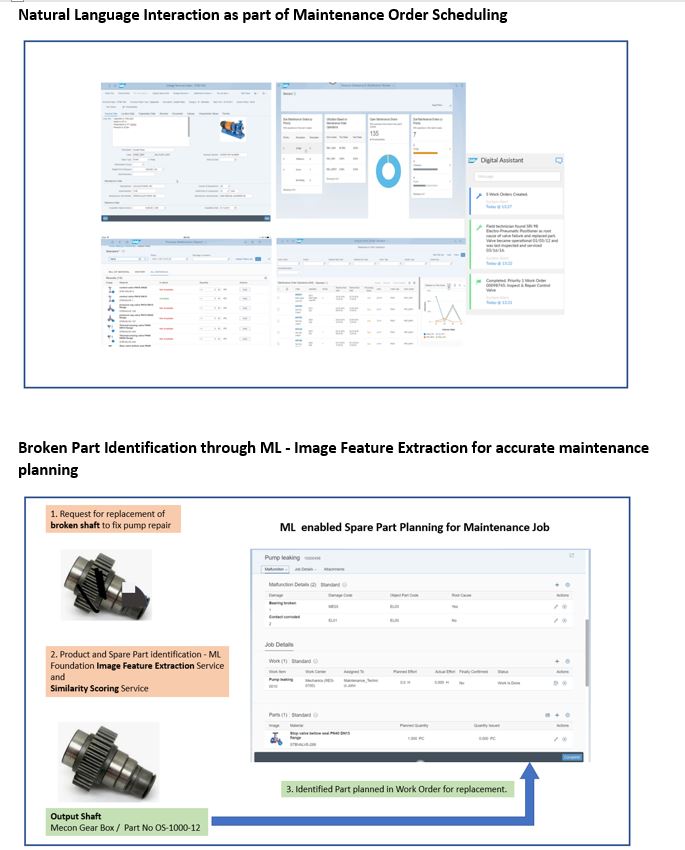

Next generation UX - User Experience based on voice, vision and messaging to replicate how people interact in real life. By enabling maintenance team to communicate in natural language with IT systems, quality of documentation will also improve significantly. All of these will enhance the data points available for ML / AI to predict better and suggest alternatives traditionally not recognized by human beings.

Value proposition and what Technologies can offer to Equipment Asset Intensive Industries are presented below:

Capabilities of Today’s Digital Technology & Business Applications:

What Next??

Ideas / opportunities are best articulated amongst stakeholders say, presales, customers, decision makers through prototypes which are easy to visualize. They should be industry agnostic and easily customizable to the specific customer industry.

Two prototypes are suggested to be set up in a demo environment based on the above ideas presented.

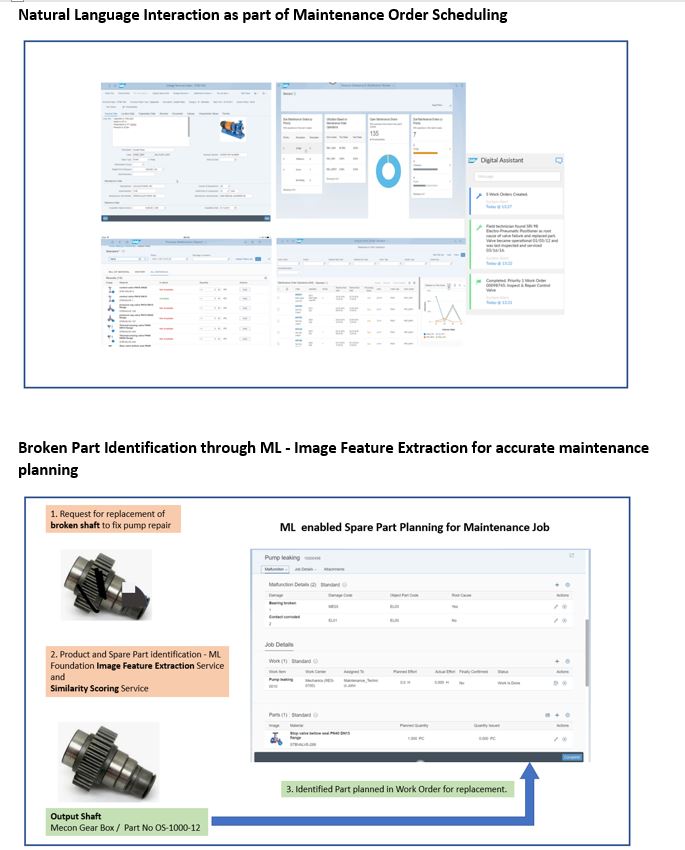

1...Maintenance order planning with visualization and collaboration amongst business partners viz, OEM, Equipment Operator and Service provider using AIN, Chatbot, etc., The intelligence of system can be demonstrated through the options it can propose for the repair say, inhouse or with external service provider based on historical transactions, recognition of broken part with pattern recognition algorithms of ML.

2. The natural language translation capability of ML can be utilized in

Job confirmation documentation with interactive voice communication and / or text based interaction.

Maintenance Request creation with interactive voice communication and / or text based interaction.

In this era of digital business transformation, what is Next to what we are currently doing? This as a constant thought process is a business imperative. It is important every management is well versed in digital technologies and have clear plans to reimagine their business models. Boundaries between the physical world, people and internet will increasingly be blurred when organizations adopt more of fourth industrial revolution (Industrie 4.0) in their existing business process.

What is Next to what we are currently doing in Equipment Asset Management world? Let us have a sneak peek. Equipment Asset operation and maintenance are typically confronted with the following business challenges:

- Attrition of existing skilled manpower due to retirements/ resignations.

- Hiring, training and retaining fresh skills as replacement.

- Existing manpower acquiring new skills in the era of rapid transformations

- Obsolescence of assets due to rapid technological innovation as well as shorter product life cycles.

Applying digital innovation to unlocking Enterprise Asset Management (EAM) business opportunities are very much possible with a fresh approach, called, Next practices in EAM processes driven by the Intelligent Enterprise.

Intelligent Technologies like SAP Leonardo – Connected Assets, IOT – Predictive Maintenance, Machine Learning / AI will support proactive maintenance planning vis a vis traditional approach of reactive and preventive maintenance. Equipment as a service (EAAS) offerings will effectively offset challenges of obsolescence and skilled resources constraint.

Next generation UX - User Experience based on voice, vision and messaging to replicate how people interact in real life. By enabling maintenance team to communicate in natural language with IT systems, quality of documentation will also improve significantly. All of these will enhance the data points available for ML / AI to predict better and suggest alternatives traditionally not recognized by human beings.

Value proposition and what Technologies can offer to Equipment Asset Intensive Industries are presented below:

Capabilities of Today’s Digital Technology & Business Applications:

What Next??

Ideas / opportunities are best articulated amongst stakeholders say, presales, customers, decision makers through prototypes which are easy to visualize. They should be industry agnostic and easily customizable to the specific customer industry.

Two prototypes are suggested to be set up in a demo environment based on the above ideas presented.

1...Maintenance order planning with visualization and collaboration amongst business partners viz, OEM, Equipment Operator and Service provider using AIN, Chatbot, etc., The intelligence of system can be demonstrated through the options it can propose for the repair say, inhouse or with external service provider based on historical transactions, recognition of broken part with pattern recognition algorithms of ML.

2. The natural language translation capability of ML can be utilized in

Job confirmation documentation with interactive voice communication and / or text based interaction.

Maintenance Request creation with interactive voice communication and / or text based interaction.

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

25 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

25 -

Expert Insights

114 -

Expert Insights

167 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,684 -

Product Updates

240 -

Roadmap and Strategy

1 -

Technology Updates

1,501 -

Technology Updates

89

Related Content

- SAP Enterprise Support Academy Newsletter May 2024 in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Finance in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Overview - Gen AI and Sustainability in Enterprise Resource Planning Blogs by SAP

- Working with SAFe Epics in the SAP Activate Discover phase in Enterprise Resource Planning Blogs by SAP

- PIR date at start of month in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 17 | |

| 5 | |

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |