- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Inspection Rounds - S/4 HANA Asset Management

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Associate

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-06-2023

9:05 PM

Inspection Rounds - S/4 HANA

Inspection rounds is a business process predominantly used in Asset Intensive Industries to inspect a series of similar process related equipment. This exercise is performed to monitor the condition of the equipment, some illustrations such as drive end temperature of lube oil pump motor, non-drive end bearing temperature of boiler feed pump etc.

An Inspection round is planned activity with a frequency of once in a week/month/day or even in shifts. Inspection rounds are always completed within one day or within one shift.

During Inspection round, the maintenance activity is performed on different technical objects, however the number of technical objects may vary depending on the sequence and time.

In this blog we are going to see how Inspection Rounds can be setup in SAP S/4 HANA system

In SAP S/4 HANA Inspection rounds can be assigned to a work center or a person.

Pre-Requisites:

To execute Inspection Rounds business process below are the key pre-requisites

Inspection Rounds Process:

Inspection rounds in S/4 HANA is carried out at the operation level of Maintenance Order by assigning the technical object for each operation.

The below pictorial representation provides a high-level process overview of Inspection rounds

Step 1: Equipment's involved in the Inspection rounds must have measuring points created in the system.

Step 2: Create Inspection plan (general task list) assigning the equipment at operation level.

Step 3: Select each operation and assign the relevant measuring point created for the Equipment as PRT respectively.

Step 4: Inspection rounds are mostly planned, and the frequency may be weekly once, monthly once or everyday depending upon the business requirement. Create Single Cycle Maintenance plan assigning the inspection plan created at Step 2.

Step 5: Schedule the Maintenance plan and generate the call (Maintenance Order), execute the inspection.

Step 6: Record the inspected measurement readings on Enter PM Order Confirmation Fiori app as per below screenshot.

Step 7: Save confirmation.

To Summarize this is the way we can use the Inspection rounds process on the current S/4HANA On-Prem system.

Thanks for your time and please share your valuable feedback and inputs in a comment below. Also kindly follow the tag SAP S/4HANA Cloud for Asset Management to watch similar content. If you find this blog useful, do follow my profile for more contents on related topics.

You can also post your questions at All Questions in SAP S/4HANA Cloud for Asset Management | SAP Community

Inspection rounds is a business process predominantly used in Asset Intensive Industries to inspect a series of similar process related equipment. This exercise is performed to monitor the condition of the equipment, some illustrations such as drive end temperature of lube oil pump motor, non-drive end bearing temperature of boiler feed pump etc.

An Inspection round is planned activity with a frequency of once in a week/month/day or even in shifts. Inspection rounds are always completed within one day or within one shift.

During Inspection round, the maintenance activity is performed on different technical objects, however the number of technical objects may vary depending on the sequence and time.

In this blog we are going to see how Inspection Rounds can be setup in SAP S/4 HANA system

In SAP S/4 HANA Inspection rounds can be assigned to a work center or a person.

Pre-Requisites:

To execute Inspection Rounds business process below are the key pre-requisites

- Business function LOG_EAM_CI_3 – Enterprise Asset Management: Continuous Improvements – for Inspection Rounds functionality should be activated

- Business function LOG_EAM_CI_4 should be activated

Inspection Rounds Process:

Inspection rounds in S/4 HANA is carried out at the operation level of Maintenance Order by assigning the technical object for each operation.

The below pictorial representation provides a high-level process overview of Inspection rounds

High Level Overview Flow

Step 1: Equipment's involved in the Inspection rounds must have measuring points created in the system.

Measuring Point for Equipment

Step 2: Create Inspection plan (general task list) assigning the equipment at operation level.

Equipment Assignment to Operations

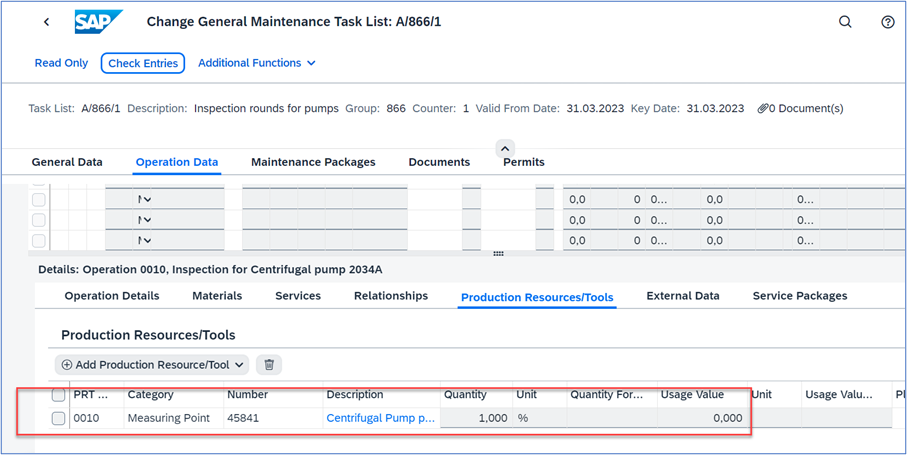

Step 3: Select each operation and assign the relevant measuring point created for the Equipment as PRT respectively.

Measuring Point -PRT Assignment to Operations

Step 4: Inspection rounds are mostly planned, and the frequency may be weekly once, monthly once or everyday depending upon the business requirement. Create Single Cycle Maintenance plan assigning the inspection plan created at Step 2.

Step 5: Schedule the Maintenance plan and generate the call (Maintenance Order), execute the inspection.

Step 6: Record the inspected measurement readings on Enter PM Order Confirmation Fiori app as per below screenshot.

Measurement Document Creation during Operation Confirmation

Step 7: Save confirmation.

To Summarize this is the way we can use the Inspection rounds process on the current S/4HANA On-Prem system.

Thanks for your time and please share your valuable feedback and inputs in a comment below. Also kindly follow the tag SAP S/4HANA Cloud for Asset Management to watch similar content. If you find this blog useful, do follow my profile for more contents on related topics.

You can also post your questions at All Questions in SAP S/4HANA Cloud for Asset Management | SAP Community

- SAP Managed Tags:

- SAP S/4HANA Cloud for Asset Management

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

24 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

160 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,684 -

Product Updates

220 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Asset Management in SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release in Enterprise Resource Planning Blogs by SAP

- Price items in Service Transactions in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 11 | |

| 10 | |

| 9 | |

| 8 | |

| 7 | |

| 7 | |

| 6 | |

| 5 | |

| 4 | |

| 4 |