- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SHEDULING TRANSPORT AGREEMENT

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

LIngeswar_1437

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-04-2023

1:40 PM

Definition:

Scheduling Transport Agreement is nothing but stock transport order where in STO we can assign one delivery date for material whereas in scheduling transport agreements we can assign pre-defined delivery dates for the material.

Back End settings for SD:

Create Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Sales and Distribution – Define, copy, delete, check sales organization

We can create Sales organization by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Sales organization by copying from the Standard one.

Create Distribution Channel:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Sales and Distribution – Define, copy, delete, check distribution channel

We can create the Distribution channel by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Distribution channel by copying from the Standard one.

Create Check Division:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Logistics general – Define, copy, delete, check division

We can create the Di vision by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Division by copying from the Standard one

Assign Sales Organization to Company Code:

Configuration: SPRO – IMG – Enterprise Structure – Assignment - Sales organization – Assign Sales organization to Company Code

Assign Distribution to Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Assign distribution channel to sales organization.

Assign Division to Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Assign Division to sales organization.

Set up Sales Area:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Setup Sales Area

In Set up Sales Area we assign Sales organization – Distribution Channel – Check Division

Check if they are assigned or not. If they are maintained Click on the new entries to assign.

Assign sales organization - distribution channel – plant:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution - Assign sales organization - distribution channel – plant

Assign Sales organization and Distribution Channel to both Supplying plant and Receiving plant

Create Customer Master:

In the case of Inter company stock transport order scenarios, the receiving plant is maintained as a customer and linked to the supplying plant while configuring.

Configuration Path:

SAP Menu – Logistics – Sales & Distribution – Master data – Business partners – Customer – Create – Complete

T - Code: XD01

Sold to Party 0001 is the Standard Account group. Here I’m using the Standard one.

For the Receiving plant is maintained as a customer and linked to the supplying Company Code while creating.

By Maintaining the all required data click on enter.

By Maintaining the required data click on the Company code Data

Enter the Reconciliation Account and click on the Sales Area Data.

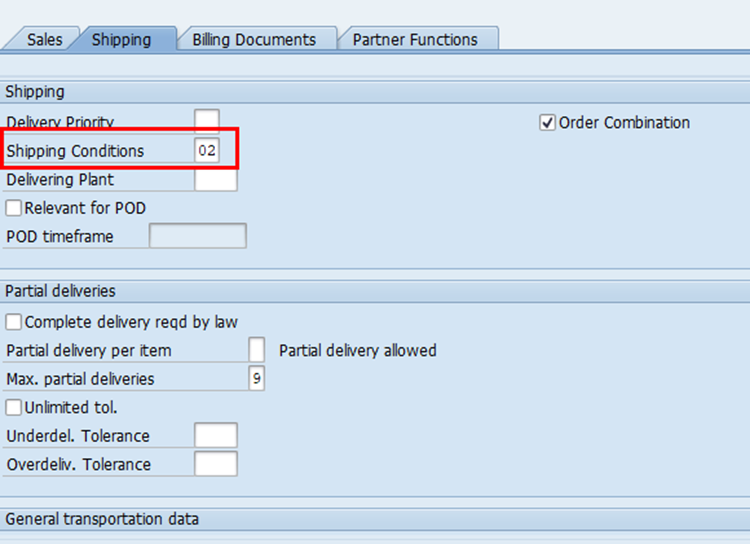

Maintain the Delivery Priority and Shipping Conditions in Shipping Data tab.

Next click on the Billing Documents to maintain Tax Classification. By Maintaining the data Click on save to create Customer master Number.

Customer Master Created Number 61.

T - CODE: VCUST – To See list of Customers

By Maintaining the required data click on Execute

These are the Configurations settings maintained from SD Side.

Now we Maintain the Configurations settings from MM:

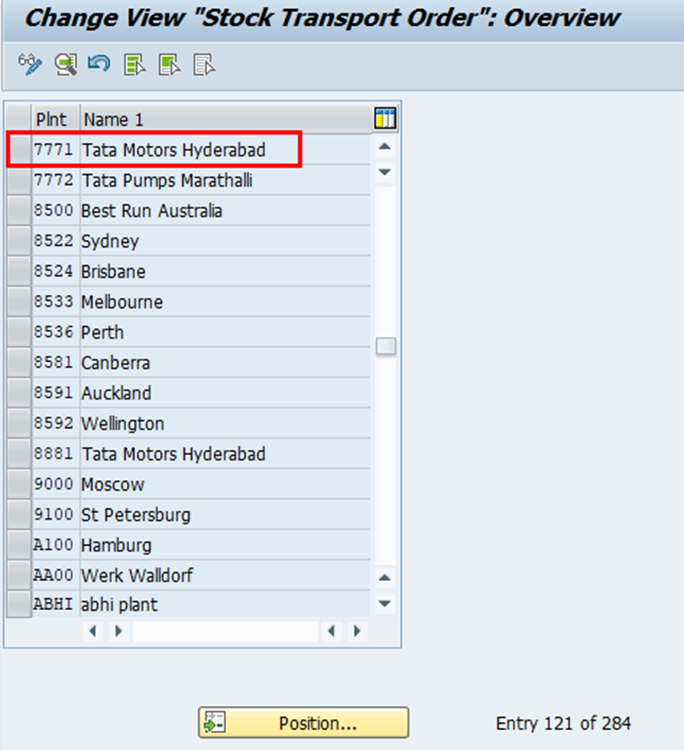

Define Shipping Data for Plants:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Define Shipping Data for Plants.

Select supplying plant maintain Sales Org, Distribution Channel, Division

Select Receiving Plant Maintain Customer Master.

Creating Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Create Checking Rule

We can create the Checking Rule by copying from the Standard one or we can enter create manually in New Entries.

Here I Create the Checking Rule by copying from the Standard one.

Define Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Define Checking Rule

We can create the Availability Check by copying from the Standard one or we can enter create manually in New Entries.

Here I Create the Availability Check by copying from the Standard one and assign Checking rule.

Assign Delivery Type and Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Assign Delivery Type and Checking Rule.

Click on New Entries Maintain and Assign Document type, supplying plant, Delivery type, and Checking Rule.

Assign Document Type:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Assign Document Type

Click on New Entries Assign Supplying plant, Receiving plant and Document Type.

These are the Configurations settings maintained from MM Side.

Process Flow:

Create Material and extend both plants:

Here I create material and extended both plants.

Select required views and enter Org levels.

In Sales Org 1 view maintains Tax data.

In Sales: General/Plant view maintain Transportation Group, Loading Group and Availability Check.

Create material number 274.

Create Vendor and assign Supplying Plant:

Here Creating vendor in Receiving Company Code and Purchase Organization.

In Purchasing Data Go to Extras click on Add. Purchasing Data maintain Supplying Plant.

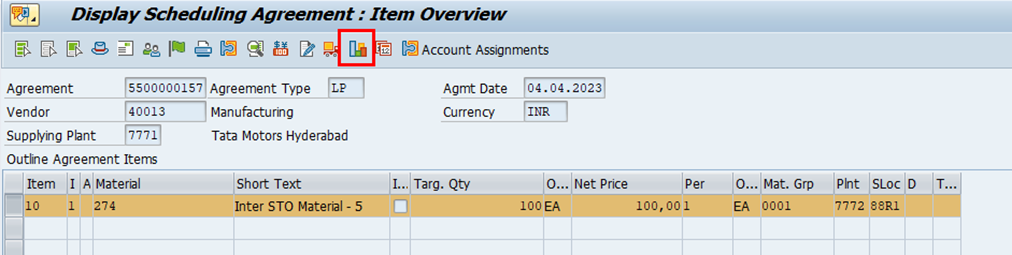

Create Scheduling Transport Agreement:

Configuration: SAP Menu – Logistics – MM – Purchasing - Outline Agreement - Scheduling Agreement – Create - Stock Transport Scheduling Agreement.

T – Code: ME37

Here maintains Supplying Plant, Agreement type and required fields etc.,

Here Maintain Validity Start and Validity End. Validity period Maintain Greater than a week.

Maintain Material Number, quantity, and Net price.

Double tap to Material maintains in Confirmation Control.

Maintain Scheduling Lines:

Configuration: SAP Menu – Logistics – MM – Purchasing - Outline Agreement - Scheduling Agreement - Delivery Schedule – Maintain

T – Code: ME38

Maintain Pre-defined delivery dates and Quantity.

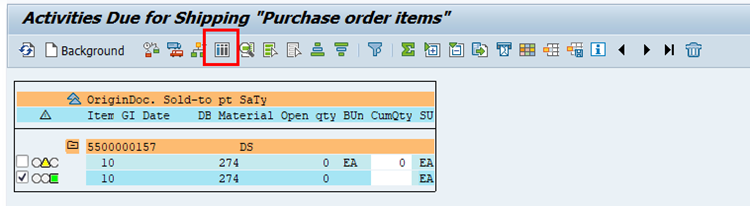

Create Outbound Delivery:

Configuration: SAP Menu – Logistics - Sales and Distribution - Shipping and Transportation - Outbound Delivery – Create - Collective Processing of Documents Due for Delivery - Purchase Order Item Schedule Line

T – Code: VL10D

Enter Shipping Point and Purchasing Document number click on Execute.

Tick the check box and click on Background

Tick the check box and click on log for delivery creation.

Place the Curser on the group and click on documents.

Post Goods Issue:

T – Code: VL02N

Enter the Picked Quantity and Storage location and click on Post Goods Issue.

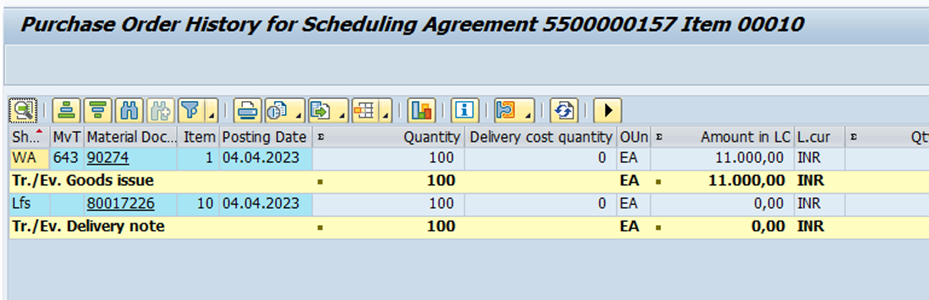

Now go to Display mode of Scheduling Transport Agreement select line Item and click on Purchase order history tab.

Goods Receipt W.R.T Outbound Delivery:

Enter Outbound delivery number tick mark for Item ok check and Post.

Material Document number 90275 is Posted.

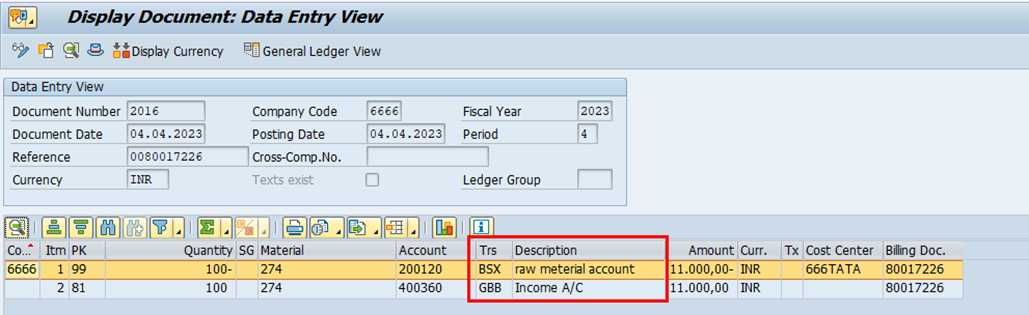

Accounting Entries:

643: BSX: Inventory A/C Credit

GBB: Consumption A/C Debit

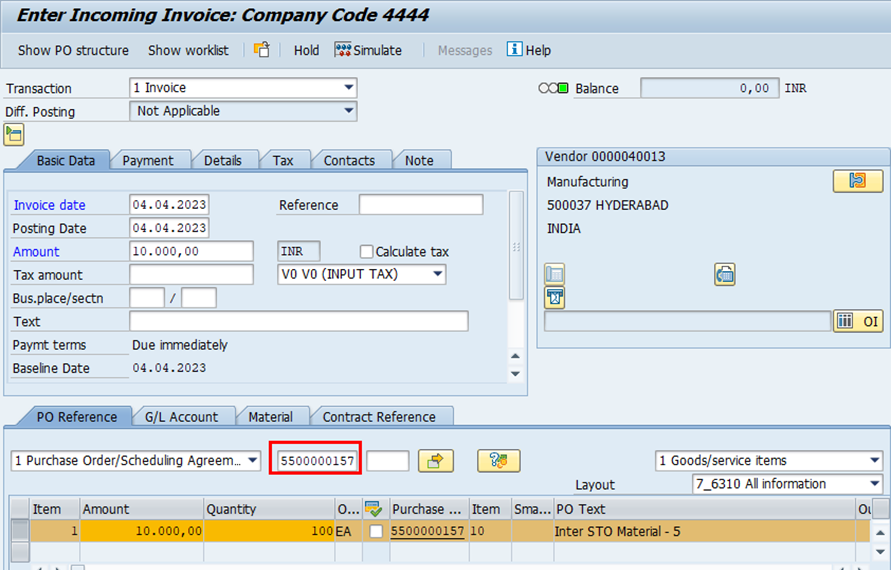

MIRO:

Enter Scheduling Transport Agreement Number, Tax code, Baseline Date and Amount. Click on Simulate Tab and Post the MIRO.

Document Number 170.

Click on Display See accounting entries.

KBS: Vendor a/c is Credit

WRX: Clearing a/c is Debit

Billing: (T – Code: VF01)

Enter Outbound Delivery Number click enter.

Billing Document number is generated. 90039013.

Scheduling Transport Agreement is nothing but stock transport order where in STO we can assign one delivery date for material whereas in scheduling transport agreements we can assign pre-defined delivery dates for the material.

Back End settings for SD:

- Create Sales organization

- Create Distribution Channel

- Create Check Division

- Set up Sales Area

- Create Customer Master

- Assign Sales Organization to Company Code

- Assign Distribution to Sales organization

- Assign Division to Sales organization

- Assign Sales organization – Distribution Channel – Plant

Create Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Sales and Distribution – Define, copy, delete, check sales organization

We can create Sales organization by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Sales organization by copying from the Standard one.

Create Distribution Channel:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Sales and Distribution – Define, copy, delete, check distribution channel

We can create the Distribution channel by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Distribution channel by copying from the Standard one.

Create Check Division:

Configuration: SPRO – IMG – Enterprise Structure – Definition – Logistics general – Define, copy, delete, check division

We can create the Di vision by copying from the Standard one or we can enter create manually in New Entries

Here I Create the Division by copying from the Standard one

Assign Sales Organization to Company Code:

Configuration: SPRO – IMG – Enterprise Structure – Assignment - Sales organization – Assign Sales organization to Company Code

Assign Distribution to Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Assign distribution channel to sales organization.

Assign Division to Sales organization:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Assign Division to sales organization.

Set up Sales Area:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution – Setup Sales Area

In Set up Sales Area we assign Sales organization – Distribution Channel – Check Division

Check if they are assigned or not. If they are maintained Click on the new entries to assign.

Assign sales organization - distribution channel – plant:

Configuration: SPRO – IMG – Enterprise Structure – Assignment – Sales and Distribution - Assign sales organization - distribution channel – plant

Assign Sales organization and Distribution Channel to both Supplying plant and Receiving plant

Create Customer Master:

In the case of Inter company stock transport order scenarios, the receiving plant is maintained as a customer and linked to the supplying plant while configuring.

Configuration Path:

SAP Menu – Logistics – Sales & Distribution – Master data – Business partners – Customer – Create – Complete

T - Code: XD01

Sold to Party 0001 is the Standard Account group. Here I’m using the Standard one.

For the Receiving plant is maintained as a customer and linked to the supplying Company Code while creating.

By Maintaining the all required data click on enter.

By Maintaining the required data click on the Company code Data

Enter the Reconciliation Account and click on the Sales Area Data.

Maintain the Delivery Priority and Shipping Conditions in Shipping Data tab.

Next click on the Billing Documents to maintain Tax Classification. By Maintaining the data Click on save to create Customer master Number.

Customer Master Created Number 61.

T - CODE: VCUST – To See list of Customers

By Maintaining the required data click on Execute

These are the Configurations settings maintained from SD Side.

Now we Maintain the Configurations settings from MM:

- Define Shipping data for plants

- Creating checking rule

- Define checking rule

- Assign delivery type and checking rule

- Assign delivery type

Define Shipping Data for Plants:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Define Shipping Data for Plants.

Select supplying plant maintain Sales Org, Distribution Channel, Division

Select Receiving Plant Maintain Customer Master.

Creating Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Create Checking Rule

We can create the Checking Rule by copying from the Standard one or we can enter create manually in New Entries.

Here I Create the Checking Rule by copying from the Standard one.

Define Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Define Checking Rule

We can create the Availability Check by copying from the Standard one or we can enter create manually in New Entries.

Here I Create the Availability Check by copying from the Standard one and assign Checking rule.

Assign Delivery Type and Checking Rule:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Assign Delivery Type and Checking Rule.

Click on New Entries Maintain and Assign Document type, supplying plant, Delivery type, and Checking Rule.

Assign Document Type:

Configuration: SPRO – IMG – MM – Purchasing – Scheduling Agreements - Set up Stock Transport Scheduling Agreement - Assign Document Type

Click on New Entries Assign Supplying plant, Receiving plant and Document Type.

These are the Configurations settings maintained from MM Side.

Process Flow:

- Create Material Master and Extend Two Plants.

- Create Vendor and Assign the supplying plant.

- Create Customer Master.

- Create Scheduling Transport Agreement (ME37/ME31L).

- Maintain Scheduling Lines.

- Create Outbound Delivery.

- Post Goods Issue.

- Goods Receipt w.r.t Outbound delivery.

- Invoice Verification.

- Billing.

Create Material and extend both plants:

Here I create material and extended both plants.

Select required views and enter Org levels.

In Sales Org 1 view maintains Tax data.

In Sales: General/Plant view maintain Transportation Group, Loading Group and Availability Check.

Create material number 274.

Create Vendor and assign Supplying Plant:

Here Creating vendor in Receiving Company Code and Purchase Organization.

In Purchasing Data Go to Extras click on Add. Purchasing Data maintain Supplying Plant.

Create Scheduling Transport Agreement:

Configuration: SAP Menu – Logistics – MM – Purchasing - Outline Agreement - Scheduling Agreement – Create - Stock Transport Scheduling Agreement.

T – Code: ME37

Here maintains Supplying Plant, Agreement type and required fields etc.,

Here Maintain Validity Start and Validity End. Validity period Maintain Greater than a week.

Maintain Material Number, quantity, and Net price.

Double tap to Material maintains in Confirmation Control.

Maintain Scheduling Lines:

Configuration: SAP Menu – Logistics – MM – Purchasing - Outline Agreement - Scheduling Agreement - Delivery Schedule – Maintain

T – Code: ME38

Maintain Pre-defined delivery dates and Quantity.

Create Outbound Delivery:

Configuration: SAP Menu – Logistics - Sales and Distribution - Shipping and Transportation - Outbound Delivery – Create - Collective Processing of Documents Due for Delivery - Purchase Order Item Schedule Line

T – Code: VL10D

Enter Shipping Point and Purchasing Document number click on Execute.

Tick the check box and click on Background

Tick the check box and click on log for delivery creation.

Place the Curser on the group and click on documents.

Post Goods Issue:

T – Code: VL02N

Enter the Picked Quantity and Storage location and click on Post Goods Issue.

Replen.Cross-Company 80017226 has been saved.

Now go to Display mode of Scheduling Transport Agreement select line Item and click on Purchase order history tab.

Goods Receipt W.R.T Outbound Delivery:

Enter Outbound delivery number tick mark for Item ok check and Post.

Material Document number 90275 is Posted.

Accounting Entries:

643: BSX: Inventory A/C Credit

GBB: Consumption A/C Debit

MIRO:

Enter Scheduling Transport Agreement Number, Tax code, Baseline Date and Amount. Click on Simulate Tab and Post the MIRO.

Document Number 170.

Click on Display See accounting entries.

KBS: Vendor a/c is Credit

WRX: Clearing a/c is Debit

Billing: (T – Code: VF01)

Enter Outbound Delivery Number click enter.

Billing Document number is generated. 90039013.

- SAP Managed Tags:

- SAP S/4HANA business partner,

- SAP S/4HANA,

- MM Inventory Management,

- MM Purchasing

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Stock Transport Scheduling Agreement (LU) Validity Dates & Aggregation in Enterprise Resource Planning Q&A

- SAP Joint venture Accounting(JVA) - Basic Concepts in Enterprise Resource Planning Blogs by Members

- Driving Sustainable Growth: The Role of Green Public Finance Management, Part 1: Understanding the Concept in Enterprise Resource Planning Blogs by SAP

- Projects in SAP in Enterprise Resource Planning Blogs by Members

- How's and Who's of Provisioning and Onboarding for SAP S/4HANA Cloud, public edition in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |