- SAP Community

- Products and Technology

- Technology

- Technology Blogs by Members

- Linear programming in ABAP. Simplex method. Find o...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This is a short post regarding linear programming (LP) and Simplex method in ABAP. I’ve tried to find some standard SAP functionality, but with no success (except a small demo program GENIOS_TEST_DEMO). Maybe I’m reinventing a wheel here, so, if somebody knows it – please let me know (maybe it could be part of PP, APO or IBP functionality).

Below you may find a simple basic description how some of LP problem can be solve via standard SAP class cl_genios_environment.

What is LP?

Linear programming (LP), also called linear optimization, is a method to achieve the best outcome (such as maximum profit or lowest cost) in a mathematical model whose requirements and objective are represented by linear relationships. Linear programming is a special case of mathematical programming (also known as mathematical optimization).

Link to the WIKI https://en.wikipedia.org/wiki/Linear_programming

Example of optimization task. Creating an optimal BOM with necessary characteristics

As one of the optimisation task which can be solved by LP let’s take this one:

We need to create a some blend from raw materials with characteristics as shown below, with components percentage:

- N >=15%,

- P >=15%,

- K >=70%.

*N/P/K is a components of a material. These components also contain in a raw materials, but in a different components percentages.

Raw material | N, % | P, % | K, % | Price per KG |

Material 1 (x1) | 12 | 12 | 76 | 35 EUR |

Material 2 (x2) | 20 | 18 | 62 | 52 EUR |

Material 3 (x3) | 12 | 18 | 70 | 40 EUR |

Material 4 (x4) | 20 | 14 | 66 | 46 EUR |

As an assumption – component percentage are mass based.

Requirements: find optimal (with less total price) bill of material (BOM) to create 1KG of this blend.

Let's create an economic-mathematical model of the problem:

Define as:

x1 – quantity of Material 1 in target blend, in kg

x2 – …Material 2, kg

x3 – …Material 3, kg

x4 – …Material 4, kg

Restriction of components percentages can be formalized as system of linear inequations :

12*<x1> + 20*<x2> + 12*<x3> + 20*<x4> ≥ 15*(<x1> + <x2> + <x3> + <x4>)

12*<x1> + 18*<x2> + 18*<x3> + 14*<x4> ≥ 15*(<x1> + <x2> + <x3> + <x4>)

76*<x1> + 62*<x2> + 70*<x3> + 66*<x4> = 70*(<x1> + <x2> + <x3> + <x4>)

Left side: percentage of N/P/K in raw materials multiply by quantity of raw materials in final blend

Right side: Target blend N/P/K characteristics

Restriction of total blend quantity should be equal to 1kg, let’s put it as an additional at the previous inequations

<x1> + <x2> + <x3> + <x4> = 1 (kg)

Final blend price function, which should be optimized is:

35*<x1> + 52*<x2> + 40*<x3> + 46*<x4> → min

This is a sum of price multiply by quantity of each raw material in target blend.

How it can be solved in math way

Let's solve the linear programming problem using the dual simplex method and simplex tables.

https://en.wikipedia.org/wiki/Simplex_algorithm

Reduce the system of inequalities to a system of equations by introducing additional variables (x5 ,x6 ,x7):

12*x1+20*x2+12*x3+20*x4+x5 = 15

12*x1+18*x2+18*x3+14*x4+x6 = 15

76*x1+62*x2+70*x3+66*x4+x7 = 70

x1+x2+x3+x4 = 1

Extended matrix of the system of equalities constraints will be:

12 | 20 | 12 | 20 | 1 | 0 | 0 | 15 |

12 | 18 | 18 | 14 | 0 | 1 | 0 | 15 |

76 | 62 | 70 | 66 | 0 | 0 | 1 | 70 |

1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

And we can find an optimal values via simplex method.

- Let's reduce matrix to the JCF https://en.wikipedia.org/wiki/Jordan_normal_form .

Base variable will be x4.

The line corresponding to the variable x4 is obtained by dividing all elements of the line x4 by the 1. In the remaining cells of the x4 column we write zeros.

Let's show the calculation of each element in the table below:

12-(1*20) | 20-(1*20) | 12-(1*20) | 20-(1*20) | 1-(0*20) | 0-(0*20) | 0-(0*20) | 15-(1*20) |

12-(1*14) | 18-(1*14) | 18-(1*14) | 14-(1*14) | 0-(0*14) | 1-(0*14) | 0-(0*14) | 15-(1*14) |

76-(1*66) | 62-(1*66) | 70-(1*66) | 66-(1*66) | 0-(0*66) | 0-(0*66) | 1-(0*66) | 70-(1*66) |

1 / 1 | 1 / 1 | 1 / 1 | 1 / 1 | 0 / 1 | 0 / 1 | 0 / 1 | 1 / 1 |

New JCF matrix will be like:

-8 | 0 | -8 | 0 | 1 | 0 | 0 | -5 |

-2 | 4 | 4 | 0 | 0 | 1 | 0 | 1 |

10 | -4 | 4 | 0 | 0 | 0 | 1 | 4 |

1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 |

- Let’s take as a basic variables x5, x6, x7 and x4 and calculate the basic variables in terms of the other variables:

x5 = 8*x1+8*x3-5

x6 = 2*x1-4*x2-4*x3+1

x7 = -10*x1+4*x2-4*x3+4

x4 = -x1-x2-x3+1

Now put them into the target function:

F(X) = 35*x1+52*x2+40*x3+46*(-x1-x2-x3+1) or F(X) = -11*x1+6*x2-6*x3+46

-8*x1-8*x3+x5=-5

-2*x1+4*x2+4*x3+x6=1

10*x1-4*x2+4*x3+x7=4

x1+x2+x3+x4=1

And create a new matrix:

-8 | 0 | -8 | 0 | 1 | 0 | 0 |

-2 | 4 | 4 | 0 | 0 | 1 | 0 |

10 | -4 | 4 | 0 | 0 | 0 | 1 |

1 | 1 | 1 | 1 | 0 | 0 | 0 |

Basic variables are variables that are included in only one equation of the system of constraints and, moreover, with a 1 coefficient.

Economic meaning of additional variables: additional variables of the LP problem indicate the surplus of raw materials, time, and other resources remaining in the production of a given optimal plan.

Let's solve the system of equations for the basic variables: x5, x6, x7, x4

Assuming that the free variables(x1,x2,x3) are equal to 0, we obtain the first possible solution (#0):

X0 = (0,0,0,1,-5,1,4)

The basic solution is acceptable if it is non-negative.

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x5 | -5 | -8 | 0 | -8 | 0 | 1 | 0 | 0 |

x6 | 1 | -2 | 4 | 4 | 0 | 0 | 1 | 0 |

x7 | 4 | 10 | -4 | 4 | 0 | 0 | 0 | 1 |

x4 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

F(X0) | 0 | 11 | -6 | 6 | 0 | 0 | 0 | 0 |

Checking the optimality criterion - Not optimal.

This possible solution (#0) in a simplex table is a pseudo-solution, so we need to determine the leading row and column.

Definition of a new free variable.

Among the negative values of the basic variables, we select the largest in absolute value.

The leading line will be the 1st line, and the variable x5 should be derived from the basis.

Definition of a new basic variable.

The minimum value of θ corresponds to the 3rd column, i.e. the variable x3 must be entered into the basis.

At the intersection of the leading row and column there is a value equal to -8.

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x5 | -5 | -8 | 0 | -8 | 0 | 1 | 0 | 0 |

x6 | 1 | -2 | 4 | 4 | 0 | 0 | 1 | 0 |

x7 | 4 | 10 | -4 | 4 | 0 | 0 | 0 | 1 |

x4 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

F(X0) | 0 | 11 | -6 | 6 | 0 | 0 | 0 | 0 |

θ | -11/8 | - | 6/-8 = | - | - | - | - |

- Recalculation of the simplex table.

Carry out transformations of the simplex table using the Gauss-Jordan method

Let's one more time show the calculation of each element in a table:

B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

-5 / -8 | -8 / -8 | 0 / -8 | -8 / -8 | 0 / -8 | 1 / -8 | 0 / -8 | 0 / -8 |

1-(-5*4) | -2-(-8*4) | 4-(0*4) | 4-(-8*4) | 0-(0*4) | 0-(1*4) | 1-(0*4) | 0-(0*4) |

4-(-5*4) | 10-(-8*4) | -4-(0*4) | 4-(-8*4) | 0-(0*4) | 0-(1*4) | 0-(0*4) | 1-(0*4) |

1-(-5*1) | 1-(-8*1) | 1-(0*1) | 1-(-8*1) | 1-(0*1) | 0-(1*1) | 0-(0*1) | 0-(0*1) |

0-(-5*6) | 11-(-8*6) | -6-(0*6) | 6-(-8*6) | 0-(0*6) | 0-(1*6) | 0-(0*6) | 0-(0*6) |

Result:

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x3 | 5/8 | 1 | 0 | 1 | 0 | -1/8 | 0 | 0 |

x6 | -3/2 | -6 | 4 | 0 | 0 | 1/2 | 1 | 0 |

x7 | 3/2 | 6 | -4 | 0 | 0 | 1/2 | 0 | 1 |

x4 | 3/8 | 0 | 1 | 0 | 1 | 1/8 | 0 | 0 |

F(X0) | -15/4 | 5 | -6 | 0 | 0 | 3/4 | 0 | 0 |

- One more time make a calculation with 2nd row and x6 and 1st column and put x1 as a basis variable.

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x3 | 5/8 | 1 | 0 | 1 | 0 | -1/8 | 0 | 0 |

x6 | -3/2 | -6 | 4 | 0 | 0 | 1/2 | 1 | 0 |

x7 | 3/2 | 6 | -4 | 0 | 0 | 1/2 | 0 | 1 |

x4 | 3/8 | 0 | 1 | 0 | 1 | 1/8 | 0 | 0 |

F(X0) | -15/4 | 5 | -6 | 0 | 0 | 3/4 | 0 | 0 |

θ | -5/6 | - | - | - | - | - | - |

- Carry out transformations of the simplex table using the Gauss-Jordan method one more time:

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x3 | 3/8 | 0 | 2/3 | 1 | 0 | -1/24 | 1/6 | 0 |

x1 | 1/4 | 1 | -2/3 | 0 | 0 | -1/12 | -1/6 | 0 |

x7 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 |

x4 | 3/8 | 0 | 1 | 0 | 1 | 1/8 | 0 | 0 |

F(X1) | -5 | 0 | -8/3 | 0 | 0 | 7/6 | 5/6 | 0 |

Here’s all elements at basis columns > 0.

Checking the optimality criterion - not optimal because there are positive coefficients in the index row.

Definition of a new basic variable - x5 as the largest coefficient.

Definition of a new free variable. min (- , - , 0 : 1 , 3/8 : 1/8 ) = 0. Therefore, the 3rd line is the leading one.

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 | min |

x3 | 3/8 | 0 | 2/3 | 1 | 0 | -1/24 | 1/6 | 0 | - |

x1 | 1/4 | 1 | -2/3 | 0 | 0 | -1/12 | -1/6 | 0 | - |

x7 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 0 |

x4 | 3/8 | 0 | 1 | 0 | 1 | 1/8 | 0 | 0 | 3 |

F(X1) | -5 | 0 | -8/3 | 0 | 0 | 7/6 | 5/6 | 0 | 0 |

- And one more time. Final simplex table will be like this:

Basis | B | x1 | x2 | x3 | x4 | x5 | x6 | x7 |

x3 | 3/8 | 0 | 2/3 | 1 | 0 | 0 | 5/24 | 1/24 |

x1 | 1/4 | 1 | -2/3 | 0 | 0 | 0 | -1/12 | 1/12 |

x5 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 |

x4 | 3/8 | 0 | 1 | 0 | 1 | 0 | -1/8 | -1/8 |

F(X) | -5 | 0 | -8/3 | 0 | 0 | 0 | -1/3 | -7/6 |

Checking the optimality criterion - Optimal!

There are no positive values among the index string values. Therefore, this table determines the optimal solution for the problem.

Final solution. Here’s an optimal quantity of raw materials which can be used to create a necessary blend:

- x1 = 0,25 kg;

- x2 = 0 kg;

- x3 = 0,375 kg;

- x4 = 0,375 kg

Optimal price will be a result of function F(X) = 35*1/4 + 52*0 + 40*3/8 + 46*3/8 = 41 EUR

SAP implementation for LP Simplex solver

At the SAP system we have a class cl_genios_environment, this is a part of a package GENIOS_MAIN in GENIOS_FRAMEWORK (system component CA-EPT-GEN «GENeric Integer Optimizer System»).

Inside this class three solvers available:

- MILP "GENIOS: Externer MILP Solver"

- SIMP "GENIOS: internal simplex solver"

- WEBS "GENIOS: WebService solver"

I’ve used a solver SIMP, this method execute all calculation according to Simplex method by standard ABAP code.

Proof of concept. ZFI_SIMP_LP_DEMO

Let’s create a simple SAP program to demonstrate how it works. It’s just a concept, so, I didn’t try to make a perfect ABAP coding…

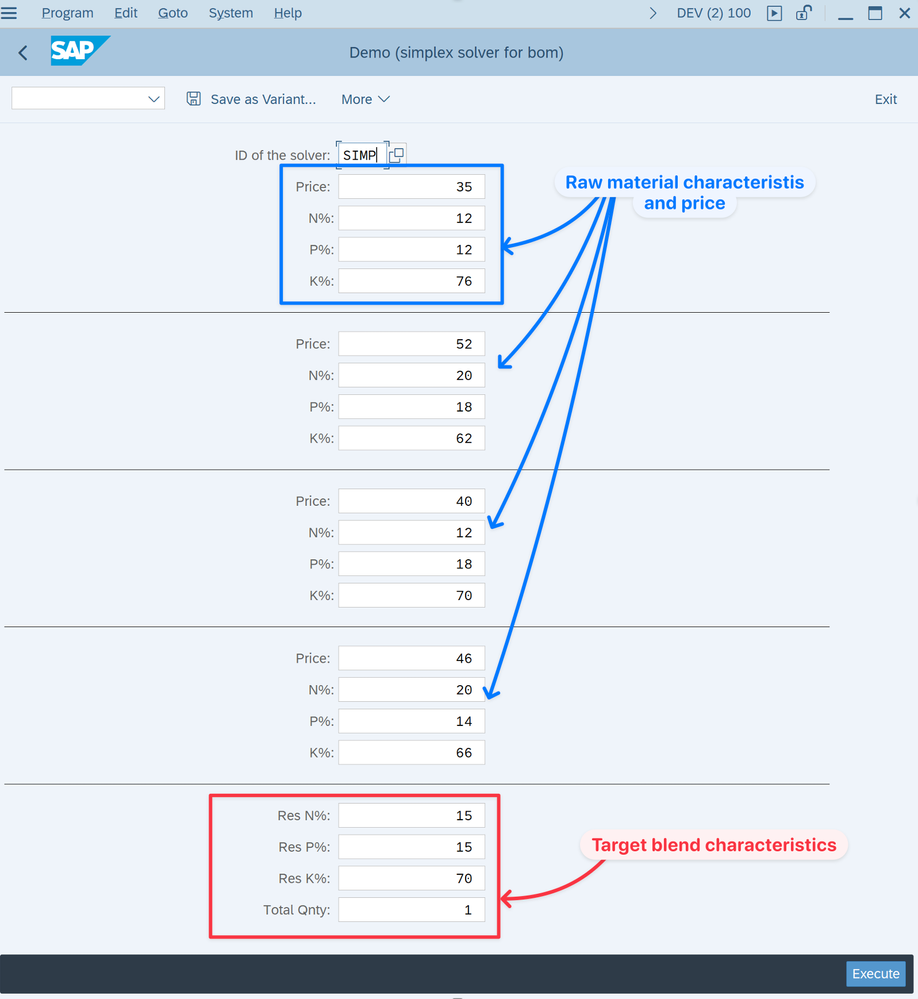

Selection screen:

At selection screen I’ve put an all data related to raw materials (N/P/K percentage and price, highlighted in blue), but in real life you can use a real data from MARA/ MARD/ MBEW/ ACDOCA etc tables.

Also, target characteristics of a blend should be specified at selection screen (bottom part of the screen, red part):

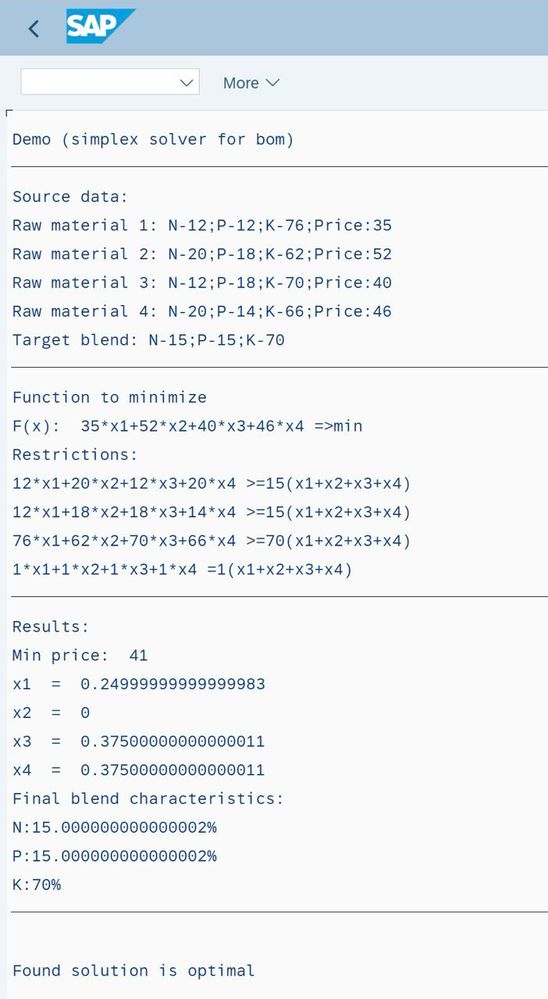

Let’s run and check a result:

So, we get a correct optimal solution for this case.

Source code with comments:

*&---------------------------------------------------------------------*

*& Report ZFI_SIMP_LP_DEMO

*&---------------------------------------------------------------------*

*& Amelin A. 2024

* LP demo. Simplex solver. Find min BOM value

*&---------------------------------------------------------------------*

REPORT zfi_simp_lp_demo.

PARAMETERS:

SolverID TYPE genios_solverid DEFAULT 'SIMP'.

PARAMETERS:

p_pr1 TYPE i DEFAULT 35,

p_n1 TYPE i DEFAULT 12,

p_p1 TYPE i DEFAULT 12,

p_k1 TYPE i DEFAULT 76.

SELECTION-SCREEN ULINE.

PARAMETERS:

p_pr2 TYPE i DEFAULT 52,

p_n2 TYPE i DEFAULT 20,

p_p2 TYPE i DEFAULT 18,

p_k2 TYPE i DEFAULT 62.

SELECTION-SCREEN ULINE.

PARAMETERS:

p_pr3 TYPE i DEFAULT 40,

p_n3 TYPE i DEFAULT 12,

p_p3 TYPE i DEFAULT 18,

p_k3 TYPE i DEFAULT 70.

SELECTION-SCREEN ULINE.

PARAMETERS:

p_pr4 TYPE i DEFAULT 46,

p_n4 TYPE i DEFAULT 20,

p_p4 TYPE i DEFAULT 14,

p_k4 TYPE i DEFAULT 66.

SELECTION-SCREEN ULINE.

PARAMETERS:

p_nt TYPE i DEFAULT 15,

p_pt TYPE i DEFAULT 15,

p_kt TYPE i DEFAULT 70,

p_tt TYPE i DEFAULT 1.

**********************************************************************

CONSTANTS:

lc_modelname TYPE genios_name VALUE 'DEMO'.

**********************************************************************

START-OF-SELECTION.

CHECK p_tt NE 0. "divide check

*Variables

DATA:

pr_1 TYPE genios_float,

pr_2 TYPE genios_float,

pr_3 TYPE genios_float,

pr_4 TYPE genios_float,

n_1 TYPE genios_float,

n_2 TYPE genios_float,

n_3 TYPE genios_float,

n_4 TYPE genios_float,

p_1 TYPE genios_float,

p_2 TYPE genios_float,

p_3 TYPE genios_float,

p_4 TYPE genios_float,

k_1 TYPE genios_float,

k_2 TYPE genios_float,

k_3 TYPE genios_float,

k_4 TYPE genios_float,

x_1 TYPE genios_float,

x_2 TYPE genios_float,

x_3 TYPE genios_float,

x_4 TYPE genios_float,

n_tot TYPE genios_float,

p_tot TYPE genios_float,

k_tot TYPE genios_float,

tt TYPE genios_float,

lo_x1 TYPE REF TO cl_genios_variable,

lo_x2 TYPE REF TO cl_genios_variable,

lo_x3 TYPE REF TO cl_genios_variable,

lo_x4 TYPE REF TO cl_genios_variable.

* 0) copy sscr data to float variables

pr_1 = p_pr1.

pr_2 = p_pr2.

pr_3 = p_pr3.

pr_4 = p_pr4.

n_1 = p_n1.

n_2 = p_n2.

n_3 = p_n3.

n_4 = p_n4.

p_1 = p_p1.

p_2 = p_p2.

p_3 = p_p3.

p_4 = p_p4.

k_1 = p_k1.

k_2 = p_k2.

k_3 = p_k3.

k_4 = p_k4.

n_tot = p_nt.

p_tot = p_pt.

k_tot = p_kt.

tt = p_tt.

* Input data. Log

WRITE: / |{ 'Source data:' }|.

WRITE: / |{ 'Raw material 1: N-' && p_n1 && ';P-' && p_p1 && ';K-' && p_k1 && ';Price:' && p_pr1 }|.

WRITE: / |{ 'Raw material 2: N-' && p_n2 && ';P-' && p_p2 && ';K-' && p_k2 && ';Price:' && p_pr2 }|.

WRITE: / |{ 'Raw material 3: N-' && p_n3 && ';P-' && p_p3 && ';K-' && p_k3 && ';Price:' && p_pr3 }|.

WRITE: / |{ 'Raw material 4: N-' && p_n4 && ';P-' && p_p4 && ';K-' && p_k4 && ';Price:' && p_pr4 }|.

WRITE: / |{ 'Target blend: N-' && p_nt && ';P-' && p_pt && ';K-' && p_kt }|.

ULINE.

DATA:

lo_env TYPE REF TO cl_genios_environment,

lx_env TYPE REF TO cx_genios_environment,

lv_msg TYPE string.

* 1) create a genios environment object

lo_env = cl_genios_environment=>get_environment( ).

DATA:

lo_model TYPE REF TO cl_genios_model.

TRY.

* 2) create a genios model (with a context-unique name)

lo_model = lo_env->create_model( lc_modelname ).

CATCH cx_genios_environment INTO lx_env.

lv_msg = lx_env->get_text( ).

WRITE: lv_msg, /.

EXIT.

ENDTRY.

* 3) fill the model with data

* 3.1) create the objective object

DATA:

lo_obj TYPE REF TO cl_genios_objective.

lo_obj = lo_model->create_objective( if_genios_model_c=>gc_obj_minimization ).

* 3.2) create the needed variables

lo_x1 = lo_model->create_variable( iv_name = 'x1' iv_type = if_genios_model_c=>gc_var_continuous ).

lo_x2 = lo_model->create_variable( iv_name = 'x2' iv_type = if_genios_model_c=>gc_var_continuous ).

lo_x3 = lo_model->create_variable( iv_name = 'x3' iv_type = if_genios_model_c=>gc_var_continuous ).

lo_x4 = lo_model->create_variable( iv_name = 'x4' iv_type = if_genios_model_c=>gc_var_continuous ).

* 3.3) add the monom for the objective function

* this is the coefficient for each variable in the objective function

lo_obj->add_monom( io_variable = lo_x1 iv_coefficient = pr_1 ). "material price

lo_obj->add_monom( io_variable = lo_x2 iv_coefficient = pr_2 ).

lo_obj->add_monom( io_variable = lo_x3 iv_coefficient = pr_3 ).

lo_obj->add_monom( io_variable = lo_x4 iv_coefficient = pr_4 ).

* 3.4) add the linear constraints with their monomes (coefficients for the variables

DATA: lo_lin TYPE REF TO cl_genios_linearconstraint.

lo_lin = lo_model->create_linearconstraint( iv_name = 'n' iv_type = if_genios_model_c=>gc_con_greaterorequal iv_righthandside = n_tot ).

lo_lin->add_monom( io_variable = lo_x1 iv_coefficient = n_1 ).

lo_lin->add_monom( io_variable = lo_x2 iv_coefficient = n_2 ).

lo_lin->add_monom( io_variable = lo_x3 iv_coefficient = n_3 ).

lo_lin->add_monom( io_variable = lo_x4 iv_coefficient = n_4 ).

lo_lin = lo_model->create_linearconstraint( iv_name = 'p' iv_type = if_genios_model_c=>gc_con_greaterorequal iv_righthandside = p_tot ).

lo_lin->add_monom( io_variable = lo_x1 iv_coefficient = p_1 ).

lo_lin->add_monom( io_variable = lo_x2 iv_coefficient = p_2 ).

lo_lin->add_monom( io_variable = lo_x3 iv_coefficient = p_3 ).

lo_lin->add_monom( io_variable = lo_x4 iv_coefficient = p_4 ).

lo_lin = lo_model->create_linearconstraint( iv_name = 'k' iv_type = if_genios_model_c=>gc_con_greaterorequal iv_righthandside = k_tot ).

lo_lin->add_monom( io_variable = lo_x1 iv_coefficient = k_1 ).

lo_lin->add_monom( io_variable = lo_x2 iv_coefficient = k_2 ).

lo_lin->add_monom( io_variable = lo_x3 iv_coefficient = k_3 ).

lo_lin->add_monom( io_variable = lo_x4 iv_coefficient = k_4 ).

lo_lin = lo_model->create_linearconstraint( iv_name = 'total' iv_type = if_genios_model_c=>gc_con_equal iv_righthandside = 1 ).

lo_lin->add_monom( io_variable = lo_x1 iv_coefficient = 1 ).

lo_lin->add_monom( io_variable = lo_x2 iv_coefficient = 1 ).

lo_lin->add_monom( io_variable = lo_x3 iv_coefficient = 1 ).

lo_lin->add_monom( io_variable = lo_x4 iv_coefficient = 1 ).

* 4) as the model is filled, we now create a solver with a ID out of tx genios_solver (in this case, the default SIMPLEX solver)

DATA:

lo_solver TYPE REF TO cl_genios_solver,

lx_solver TYPE REF TO cx_genios_solver.

TRY.

lo_solver ?= lo_env->create_solver( SolverID ).

CATCH cx_genios_environment INTO lx_env.

lv_msg = lx_env->get_text( ).

WRITE: lv_msg, /.

EXIT.

ENDTRY.

* 4.1) load the model into the solver and solve it

DATA:

ls_result TYPE genioss_solver_result,

lo_param TYPE REF TO cl_genios_parameter.

TRY.

CREATE OBJECT lo_param

EXPORTING

iv_solver_id = lo_solver->get_solverid( ).

lo_param->mv_timelimit = 300. " its a good idea to se a runtime - its only relevant for MILP runs, but ...

lo_solver->load_model( lo_model ).

ls_result = lo_solver->solve( lo_param ).

CATCH cx_genios_solver INTO lx_solver.

lv_msg = lx_solver->get_text( ).

WRITE: lv_msg, /.

EXIT.

ENDTRY.

* 4.2) evaluate the results

DATA:

lt_variables TYPE geniost_variable,

ls_variable TYPE genioss_variable,

lv_primalvalue TYPE genios_float,

lv_name TYPE string,

lv_index TYPE string.

IF ( ls_result-solution_status = if_genios_solver_result_c=>gc_optimal

OR ls_result-solution_status = if_genios_solver_result_c=>gc_abortfeasible ).

* 4.3) found a solution => output the objective value as well as the variable values

lv_primalvalue = lo_obj->get_value( ).

WRITE: / 'Function to minimize'.

WRITE: / 'F(x): ', |{ p_pr1 && '*x1+' && p_pr2 && '*x2+' && p_pr3 && '*x3+' && p_pr4 && '*x4 =>min' }|.

WRITE: / 'Restrictions:'.

WRITE: / |{ p_n1 && '*x1+' && p_n2 && '*x2+' && p_n3 && '*x3+' && p_n4 && '*x4 >=' && n_tot && '(x1+x2+x3+x4)' }|.

WRITE: / |{ p_p1 && '*x1+' && p_p2 && '*x2+' && p_p3 && '*x3+' && p_p4 && '*x4 >=' && p_tot && '(x1+x2+x3+x4)' }|.

WRITE: / |{ p_k1 && '*x1+' && p_k2 && '*x2+' && p_k3 && '*x3+' && p_k4 && '*x4 >=' && k_tot && '(x1+x2+x3+x4)' }|.

WRITE: / |{ tt && '*x1+' && tt && '*x2+' && tt && '*x3+' && tt && '*x4 =' && tt && '(x1+x2+x3+x4)' }|.

ULINE.

WRITE: / 'Results:'.

WRITE: /'Min price: ', |{ lv_primalvalue * tt }|. "#EC NOTEXT

lt_variables = lo_model->get_variables( ).

LOOP AT lt_variables INTO ls_variable.

lv_primalvalue = 0.

lv_name = ls_variable-variable_ref->gv_name.

lv_index = ls_variable-variable_index.

lv_primalvalue = ls_variable-variable_ref->get_primalvalue( ).

WRITE: / lv_name,' = ',|{ lv_primalvalue * tt }|.

IF lv_name = 'x1'.

x_1 = lv_primalvalue * tt.

ELSEIF lv_name = 'x2'.

x_2 = lv_primalvalue * tt.

ELSEIF lv_name = 'x3'.

x_3 = lv_primalvalue * tt.

ELSEIF lv_name = 'x4'.

x_4 = lv_primalvalue * tt.

ENDIF.

ENDLOOP.

WRITE: / 'Final blend characteristics:'.

WRITE: / 'N:' && |{ ( ( ( x_1 * p_n1 ) + ( x_2 * p_n2 ) + ( x_3 * p_n3 ) + ( x_4 * p_n4 ) ) / tt ) }| && '%'.

WRITE: / 'P:' && |{ ( ( ( x_1 * p_p1 ) + ( x_2 * p_p2 ) + ( x_3 * p_p3 ) + ( x_4 * p_p4 ) ) / tt ) }| && '%'.

WRITE: / 'K:' && |{ ( ( ( x_1 * p_k1 ) + ( x_2 * p_k2 ) + ( x_3 * p_k3 ) + ( x_4 * p_k4 ) ) / tt ) }| && '%'.

ENDIF.

ULINE.

* 4.4) output the solution status

IF ( ls_result-solution_status = if_genios_solver_result_c=>gc_optimal ).

WRITE: /,'Found solution is optimal'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_abortfeasible ).

WRITE: /,'Solver aborted with a feasible solution'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_abortinfeasible ).

WRITE: /,'Solver aborted with an infeasible solution'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_failinfeasible ).

WRITE: /,'Solver failed due to infeasibility'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_solutionlimitreached ).

WRITE: /,'Solution limit reached, but the a solution has been found'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_timelimitinfeasible ).

WRITE: /,'Time limit reached and the solution is infeasible'.

ELSEIF ( ls_result-solution_status = if_genios_solver_result_c=>gc_unknown ).

WRITE: /,'Solution status is unknown'.

ENDIF.

* 5) some cleanup

IF ( lo_env IS BOUND ).

lo_env->destroy_solver( SolverID ).

lo_env->destroy_model( lc_modelname ).

ENDIF.

- SAP Managed Tags:

- ABAP Development,

- SAP ERP,

- SAP S/4HANA

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"automatische backups"

1 -

"regelmäßige sicherung"

1 -

"TypeScript" "Development" "FeedBack"

1 -

505 Technology Updates 53

1 -

ABAP

14 -

ABAP API

1 -

ABAP CDS Views

2 -

ABAP CDS Views - BW Extraction

1 -

ABAP CDS Views - CDC (Change Data Capture)

1 -

ABAP class

2 -

ABAP Cloud

3 -

ABAP Development

5 -

ABAP in Eclipse

1 -

ABAP Platform Trial

1 -

ABAP Programming

2 -

abap technical

1 -

abapGit

1 -

absl

2 -

access data from SAP Datasphere directly from Snowflake

1 -

Access data from SAP datasphere to Qliksense

1 -

Accrual

1 -

action

1 -

adapter modules

1 -

Addon

1 -

Adobe Document Services

1 -

ADS

1 -

ADS Config

1 -

ADS with ABAP

1 -

ADS with Java

1 -

ADT

2 -

Advance Shipping and Receiving

1 -

Advanced Event Mesh

3 -

Advanced formula

1 -

AEM

1 -

AI

8 -

AI Launchpad

1 -

AI Projects

1 -

AIML

9 -

Alert in Sap analytical cloud

1 -

Amazon S3

1 -

Analytical Dataset

1 -

Analytical Model

1 -

Analytics

1 -

Analyze Workload Data

1 -

annotations

1 -

API

1 -

API and Integration

3 -

API Call

2 -

API security

1 -

Application Architecture

1 -

Application Development

5 -

Application Development for SAP HANA Cloud

3 -

Applications and Business Processes (AP)

1 -

Artificial Intelligence

1 -

Artificial Intelligence (AI)

5 -

Artificial Intelligence (AI) 1 Business Trends 363 Business Trends 8 Digital Transformation with Cloud ERP (DT) 1 Event Information 462 Event Information 15 Expert Insights 114 Expert Insights 76 Life at SAP 418 Life at SAP 1 Product Updates 4

1 -

Artificial Intelligence (AI) blockchain Data & Analytics

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise Oil Gas IoT Exploration Production

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise sustainability responsibility esg social compliance cybersecurity risk

1 -

ASE

1 -

ASR

2 -

ASUG

1 -

Attachments

1 -

Authorisations

1 -

Automating Processes

1 -

Automation

2 -

aws

2 -

Azure

1 -

Azure AI Studio

1 -

Azure API Center

1 -

Azure API Management

1 -

B2B Integration

1 -

Backorder Processing

1 -

Backup

1 -

Backup and Recovery

1 -

Backup schedule

1 -

BADI_MATERIAL_CHECK error message

1 -

Bank

1 -

Bank Communication Management

1 -

BAS

1 -

basis

2 -

Basis Monitoring & Tcodes with Key notes

2 -

Batch Management

1 -

BDC

1 -

Best Practice

1 -

bitcoin

1 -

Blockchain

3 -

bodl

1 -

BOP in aATP

1 -

BOP Segments

1 -

BOP Strategies

1 -

BOP Variant

1 -

BPC

1 -

BPC LIVE

1 -

BTP

13 -

BTP AI Launchpad

1 -

BTP Destination

2 -

Business AI

1 -

Business and IT Integration

1 -

Business application stu

1 -

Business Application Studio

1 -

Business Architecture

1 -

Business Communication Services

1 -

Business Continuity

1 -

Business Data Fabric

3 -

Business Fabric

1 -

Business Partner

12 -

Business Partner Master Data

10 -

Business Technology Platform

2 -

Business Trends

4 -

BW4HANA

1 -

CA

1 -

calculation view

1 -

CAP

4 -

Capgemini

1 -

CAPM

1 -

Catalyst for Efficiency: Revolutionizing SAP Integration Suite with Artificial Intelligence (AI) and

1 -

CCMS

2 -

CDQ

12 -

CDS

2 -

Cental Finance

1 -

Certificates

1 -

CFL

1 -

Change Management

1 -

chatbot

1 -

chatgpt

3 -

CL_SALV_TABLE

2 -

Class Runner

1 -

Classrunner

1 -

Cloud ALM Monitoring

1 -

Cloud ALM Operations

1 -

cloud connector

1 -

Cloud Extensibility

1 -

Cloud Foundry

4 -

Cloud Integration

6 -

Cloud Platform Integration

2 -

cloudalm

1 -

communication

1 -

Compensation Information Management

1 -

Compensation Management

1 -

Compliance

1 -

Compound Employee API

1 -

Configuration

1 -

Connectors

1 -

Consolidation Extension for SAP Analytics Cloud

2 -

Control Indicators.

1 -

Controller-Service-Repository pattern

1 -

Conversion

1 -

Cosine similarity

1 -

cryptocurrency

1 -

CSI

1 -

ctms

1 -

Custom chatbot

3 -

Custom Destination Service

1 -

custom fields

1 -

Customer Experience

1 -

Customer Journey

1 -

Customizing

1 -

cyber security

4 -

cybersecurity

1 -

Data

1 -

Data & Analytics

1 -

Data Aging

1 -

Data Analytics

2 -

Data and Analytics (DA)

1 -

Data Archiving

1 -

Data Back-up

1 -

Data Flow

1 -

Data Governance

5 -

Data Integration

2 -

Data Quality

12 -

Data Quality Management

12 -

Data Synchronization

1 -

data transfer

1 -

Data Unleashed

1 -

Data Value

8 -

database tables

1 -

Dataframe

1 -

Datasphere

3 -

datenbanksicherung

1 -

dba cockpit

1 -

dbacockpit

1 -

Debugging

2 -

Defender

1 -

Delimiting Pay Components

1 -

Delta Integrations

1 -

Destination

3 -

Destination Service

1 -

Developer extensibility

1 -

Developing with SAP Integration Suite

1 -

Devops

1 -

digital transformation

1 -

Documentation

1 -

Dot Product

1 -

DQM

1 -

dump database

1 -

dump transaction

1 -

e-Invoice

1 -

E4H Conversion

1 -

Eclipse ADT ABAP Development Tools

2 -

edoc

1 -

edocument

1 -

ELA

1 -

Embedded Consolidation

1 -

Embedding

1 -

Embeddings

1 -

Employee Central

1 -

Employee Central Payroll

1 -

Employee Central Time Off

1 -

Employee Information

1 -

Employee Rehires

1 -

Enable Now

1 -

Enable now manager

1 -

endpoint

1 -

Enhancement Request

1 -

Enterprise Architecture

1 -

ESLint

1 -

ETL Business Analytics with SAP Signavio

1 -

Euclidean distance

1 -

Event Dates

1 -

Event Driven Architecture

1 -

Event Mesh

2 -

Event Reason

1 -

EventBasedIntegration

1 -

EWM

1 -

EWM Outbound configuration

1 -

EWM-TM-Integration

1 -

Existing Event Changes

1 -

Expand

1 -

Expert

2 -

Expert Insights

2 -

Exploits

1 -

Fiori

14 -

Fiori Elements

2 -

Fiori SAPUI5

12 -

first-guidance

1 -

Flask

1 -

FTC

1 -

Full Stack

8 -

Funds Management

1 -

gCTS

1 -

GenAI hub

1 -

General

1 -

Generative AI

1 -

Getting Started

1 -

GitHub

9 -

Grants Management

1 -

groovy

1 -

GTP

1 -

HANA

6 -

HANA Cloud

2 -

Hana Cloud Database Integration

2 -

HANA DB

2 -

Hana Vector Engine

1 -

HANA XS Advanced

1 -

Historical Events

1 -

home labs

1 -

HowTo

1 -

HR Data Management

1 -

html5

8 -

HTML5 Application

1 -

Identity cards validation

1 -

idm

1 -

Implementation

1 -

Infuse AI

1 -

input parameter

1 -

instant payments

1 -

Integration

3 -

Integration Advisor

1 -

Integration Architecture

1 -

Integration Center

1 -

Integration Suite

1 -

intelligent enterprise

1 -

iot

1 -

Java

1 -

job

1 -

Job Information Changes

1 -

Job-Related Events

1 -

Job_Event_Information

1 -

joule

4 -

Journal Entries

1 -

Just Ask

1 -

Kerberos for ABAP

8 -

Kerberos for JAVA

8 -

KNN

1 -

Launch Wizard

1 -

Learning Content

2 -

Life at SAP

5 -

lightning

1 -

Linear Regression SAP HANA Cloud

1 -

Loading Indicator

1 -

local tax regulations

1 -

LP

1 -

Machine Learning

4 -

Marketing

1 -

Master Data

3 -

Master Data Management

14 -

Maxdb

2 -

MDG

1 -

MDGM

1 -

MDM

1 -

Message box.

1 -

Messages on RF Device

1 -

Microservices Architecture

1 -

Microsoft Universal Print

1 -

Middleware Solutions

1 -

Migration

5 -

ML Model Development

1 -

Modeling in SAP HANA Cloud

8 -

Monitoring

3 -

MTA

1 -

Multi-Record Scenarios

1 -

Multilayer Perceptron

1 -

Multiple Event Triggers

1 -

Myself Transformation

1 -

Neo

1 -

Neural Networks

1 -

New Event Creation

1 -

New Feature

1 -

Newcomer

1 -

NodeJS

3 -

ODATA

2 -

OData APIs

1 -

odatav2

1 -

ODATAV4

1 -

ODBC

1 -

ODBC Connection

1 -

Onpremise

1 -

open source

2 -

OpenAI API

1 -

Oracle

1 -

PaPM

1 -

PaPM Dynamic Data Copy through Writer function

1 -

PaPM Remote Call

1 -

Partner Built Foundation Model

1 -

PAS-C01

1 -

Pay Component Management

1 -

PGP

1 -

Pickle

1 -

PLANNING ARCHITECTURE

1 -

Popup in Sap analytical cloud

1 -

PostgrSQL

1 -

POSTMAN

1 -

Prettier

1 -

Process Automation

2 -

Product Updates

6 -

PSM

1 -

Public Cloud

1 -

Python

4 -

python library - Document information extraction service

1 -

Qlik

1 -

Qualtrics

1 -

RAP

3 -

RAP BO

2 -

Record Deletion

1 -

Recovery

1 -

recurring payments

1 -

redeply

1 -

Release

1 -

Remote Consumption Model

1 -

Replication Flows

1 -

research

1 -

Resilience

1 -

REST

1 -

REST API

1 -

Retagging Required

1 -

Risk

1 -

Rolling Kernel Switch

1 -

route

1 -

rules

1 -

S4 HANA

1 -

S4 HANA Cloud

1 -

S4 HANA On-Premise

1 -

S4HANA

4 -

S4HANA Cloud

1 -

S4HANA_OP_2023

2 -

SAC

10 -

SAC PLANNING

9 -

SAP

4 -

SAP ABAP

1 -

SAP Advanced Event Mesh

1 -

SAP AI Core

9 -

SAP AI Launchpad

8 -

SAP Analytic Cloud Compass

1 -

Sap Analytical Cloud

1 -

SAP Analytics Cloud

4 -

SAP Analytics Cloud for Consolidation

3 -

SAP Analytics Cloud Story

1 -

SAP analytics clouds

1 -

SAP API Management

1 -

SAP BAS

1 -

SAP Basis

6 -

SAP BODS

1 -

SAP BODS certification.

1 -

SAP BTP

22 -

SAP BTP Build Work Zone

2 -

SAP BTP Cloud Foundry

6 -

SAP BTP Costing

1 -

SAP BTP CTMS

1 -

SAP BTP Generative AI

1 -

SAP BTP Innovation

1 -

SAP BTP Migration Tool

1 -

SAP BTP SDK IOS

1 -

SAP BTPEA

1 -

SAP Build

11 -

SAP Build App

1 -

SAP Build apps

1 -

SAP Build CodeJam

1 -

SAP Build Process Automation

3 -

SAP Build work zone

10 -

SAP Business Objects Platform

1 -

SAP Business Technology

2 -

SAP Business Technology Platform (XP)

1 -

sap bw

1 -

SAP CAP

2 -

SAP CDC

1 -

SAP CDP

1 -

SAP CDS VIEW

1 -

SAP Certification

1 -

SAP Cloud ALM

4 -

SAP Cloud Application Programming Model

1 -

SAP Cloud Integration for Data Services

1 -

SAP cloud platform

8 -

SAP Companion

1 -

SAP CPI

3 -

SAP CPI (Cloud Platform Integration)

2 -

SAP CPI Discover tab

1 -

sap credential store

1 -

SAP Customer Data Cloud

1 -

SAP Customer Data Platform

1 -

SAP Data Intelligence

1 -

SAP Data Migration in Retail Industry

1 -

SAP Data Services

1 -

SAP DATABASE

1 -

SAP Dataspher to Non SAP BI tools

1 -

SAP Datasphere

9 -

SAP DRC

1 -

SAP EWM

1 -

SAP Fiori

3 -

SAP Fiori App Embedding

1 -

Sap Fiori Extension Project Using BAS

1 -

SAP GRC

1 -

SAP HANA

1 -

SAP HANA PAL

1 -

SAP HANA Vector

1 -

SAP HCM (Human Capital Management)

1 -

SAP HR Solutions

1 -

SAP IDM

1 -

SAP Integration Suite

9 -

SAP Integrations

4 -

SAP iRPA

2 -

SAP LAGGING AND SLOW

1 -

SAP Learning Class

1 -

SAP Learning Hub

1 -

SAP Master Data

1 -

SAP Odata

2 -

SAP on Azure

2 -

SAP PAL

1 -

SAP PartnerEdge

1 -

sap partners

1 -

SAP Password Reset

1 -

SAP PO Migration

1 -

SAP Prepackaged Content

1 -

SAP Process Automation

2 -

SAP Process Integration

2 -

SAP Process Orchestration

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Cloud for Finance

1 -

SAP S4HANA Cloud private edition

1 -

SAP Sandbox

1 -

SAP STMS

1 -

SAP successfactors

3 -

SAP SuccessFactors HXM Core

1 -

SAP Time

1 -

SAP TM

2 -

SAP Trading Partner Management

1 -

SAP UI5

1 -

SAP Upgrade

1 -

SAP Utilities

1 -

SAP-GUI

8 -

SAP_COM_0276

1 -

SAPBTP

1 -

SAPCPI

1 -

SAPEWM

1 -

sapfirstguidance

1 -

SAPHANAService

1 -

SAPIQ

1 -

sapmentors

1 -

saponaws

2 -

SAPS4HANA

1 -

SAPUI5

5 -

schedule

1 -

Script Operator

1 -

Secure Login Client Setup

8 -

security

9 -

Selenium Testing

1 -

Self Transformation

1 -

Self-Transformation

1 -

SEN

1 -

SEN Manager

1 -

service

1 -

SET_CELL_TYPE

1 -

SET_CELL_TYPE_COLUMN

1 -

SFTP scenario

2 -

Simplex

1 -

Single Sign On

8 -

Singlesource

1 -

SKLearn

1 -

Slow loading

1 -

soap

1 -

Software Development

1 -

SOLMAN

1 -

solman 7.2

2 -

Solution Manager

3 -

sp_dumpdb

1 -

sp_dumptrans

1 -

SQL

1 -

sql script

1 -

SSL

8 -

SSO

8 -

Substring function

1 -

SuccessFactors

1 -

SuccessFactors Platform

1 -

SuccessFactors Time Tracking

1 -

Sybase

1 -

system copy method

1 -

System owner

1 -

Table splitting

1 -

Tax Integration

1 -

Technical article

1 -

Technical articles

1 -

Technology Updates

15 -

Technology Updates

1 -

Technology_Updates

1 -

terraform

1 -

Threats

2 -

Time Collectors

1 -

Time Off

2 -

Time Sheet

1 -

Time Sheet SAP SuccessFactors Time Tracking

1 -

Tips and tricks

2 -

toggle button

1 -

Tools

1 -

Trainings & Certifications

1 -

Transformation Flow

1 -

Transport in SAP BODS

1 -

Transport Management

1 -

TypeScript

3 -

ui designer

1 -

unbind

1 -

Unified Customer Profile

1 -

UPB

1 -

Use of Parameters for Data Copy in PaPM

1 -

User Unlock

1 -

VA02

1 -

Validations

1 -

Vector Database

2 -

Vector Engine

1 -

Vectorization

1 -

Visual Studio Code

1 -

VSCode

2 -

VSCode extenions

1 -

Vulnerabilities

1 -

Web SDK

1 -

work zone

1 -

workload

1 -

xsa

1 -

XSA Refresh

1

- « Previous

- Next »

- SAP Mobile Start provides the best user experience, leveraging native Apple platform capabilities in Technology Blogs by SAP

- SAP Business Technology Platform Concepts in Technology Blogs by SAP

- Financial planning : SAP Analytics Cloud to replace SAP Business Planning & Consolidation ? in Technology Blogs by Members

- Code Pushdown in Technology Blogs by Members

| User | Count |

|---|---|

| 10 | |

| 9 | |

| 5 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 |