- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- SAP Best Practices for SAP Integrated Business Pla...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-04-2023

12:39 PM

I hope you enjoy the summertime. We delivered begin of August our summer version of the SAP Best Practices for SAP Integrated Business Planning for Supply Chain 2308.

The list of highlights of the 2308 release starts with a complete new solution process for IBP for Maintenance, Repair, and Operations:

IBP for Maintenance, Repair, and Operations (MRO) (75C):

With 2308, we provide a first solution process for IBP for Maintenance, Repair, and Operations.

The purpose of integrated maintenance, repair, and operations planning is to provide full transparency for mid-term and long-term MRO parts and resource requirements by leveraging statistical forecasting methods, inventory and supply planning algorithms.

In a first step, the inventory planner needs to check the updated MRO parts usage history at the beginning of each planning cycle. During this task, the planner also segments the MRO parts based on historical demand pattern. The maintenance planner then creates MRO part and resource consumption corrective maintenance forecasts for a period of 12 months for mid-term forecasting.

After that, the inventory planner carries out an MRO part segmentation analysis in which parts are segmented based on their costs and usage volumes as well as their lead time risk. Once the service levels are defined, the inventory planner creates an inventory plan and determines the new safety stock, reorder point or target inventory position for MRO parts being planned. After the inventory parameters are defined, the maintenance planner can create a supply plan for MRO parts and labor resources for the mid- to long-term horizon. Upon completion of the supply plan, the financial calculations are populated in the planning area which can be reviewed by a finance manager. Finally, the finance manager can approve the expected maintenance expenditures and complete the cycle of the integrated business plan for maintenance, repair, and operations.

Here you can find more details and further information.

OBP Optimizer

The solution process IBP for response and supply – supply planning – OBP optimizer (42C) (formerly known as IBP for response and supply - supply and allocations planning - optimizer) has been enhanced with an example showcasing the telescopic planning, which uses different planning granularities throughout the planning horizon. A second enhancement is subcontracting. To show the subcontracting process, we enhanced the sample supply chain network with two subcontractors, providing the sub-assembly of one semi-finished product to the production plants. To check the results, means here the subcontracting component demand and the total receipt key figures for a subcontractor, you can use the extended excel planning view or the Projected Stock app.

Planner Workspaces

Planner Workspace (PWS) is a configurable work environment where you can plan, analyze issues in your plans, and solve these issues with the help of custom alerts and simulations. In 2308 we have two enhancements that you can use very easily when creating a new planning area based on SAP7F or SAPIBP1 sample planning area. When activating "Copy Planner Workspaces, Analytics, and Alerts" for SAP7F, the following planner workspaces are automatically provided, and no manual configuration is needed:

If you are using SAPIBP1 as a base, you can use the following PWS:

Cost rollup

The solution process IBP for sales and operations – supply review – heuristic has been enhanced with a cost rollup example. The new Network Aggregation operator calculates the unit cost of a product at a location and period by rolling-up cost incurred at various places in the upstream supply chain. Examples of such costs are transportation, production, inventory maintenance, and components. The results of the operator help to estimate the margin and profitability at a granular level of customer / product / location. You can calculate the contribution of various cost components like transport, production, and inventory to the unit cost of a finished product.

Enhancements and changes for Sample Model SAPIBP1

Do you want to access the new content via SAP Signavio Process Navigator? Here you find everything you need.

Do you want to learn more about the usage of SAP Signavio Process Navigator? Please check out this short video.

The list of highlights of the 2308 release starts with a complete new solution process for IBP for Maintenance, Repair, and Operations:

IBP for Maintenance, Repair, and Operations (MRO) (75C):

With 2308, we provide a first solution process for IBP for Maintenance, Repair, and Operations.

The purpose of integrated maintenance, repair, and operations planning is to provide full transparency for mid-term and long-term MRO parts and resource requirements by leveraging statistical forecasting methods, inventory and supply planning algorithms.

In a first step, the inventory planner needs to check the updated MRO parts usage history at the beginning of each planning cycle. During this task, the planner also segments the MRO parts based on historical demand pattern. The maintenance planner then creates MRO part and resource consumption corrective maintenance forecasts for a period of 12 months for mid-term forecasting.

After that, the inventory planner carries out an MRO part segmentation analysis in which parts are segmented based on their costs and usage volumes as well as their lead time risk. Once the service levels are defined, the inventory planner creates an inventory plan and determines the new safety stock, reorder point or target inventory position for MRO parts being planned. After the inventory parameters are defined, the maintenance planner can create a supply plan for MRO parts and labor resources for the mid- to long-term horizon. Upon completion of the supply plan, the financial calculations are populated in the planning area which can be reviewed by a finance manager. Finally, the finance manager can approve the expected maintenance expenditures and complete the cycle of the integrated business plan for maintenance, repair, and operations.

Here you can find more details and further information.

Screenshot IBP for MRO

OBP Optimizer

The solution process IBP for response and supply – supply planning – OBP optimizer (42C) (formerly known as IBP for response and supply - supply and allocations planning - optimizer) has been enhanced with an example showcasing the telescopic planning, which uses different planning granularities throughout the planning horizon. A second enhancement is subcontracting. To show the subcontracting process, we enhanced the sample supply chain network with two subcontractors, providing the sub-assembly of one semi-finished product to the production plants. To check the results, means here the subcontracting component demand and the total receipt key figures for a subcontractor, you can use the extended excel planning view or the Projected Stock app.

Sample supply chain network

Planner Workspaces

Planner Workspace (PWS) is a configurable work environment where you can plan, analyze issues in your plans, and solve these issues with the help of custom alerts and simulations. In 2308 we have two enhancements that you can use very easily when creating a new planning area based on SAP7F or SAPIBP1 sample planning area. When activating "Copy Planner Workspaces, Analytics, and Alerts" for SAP7F, the following planner workspaces are automatically provided, and no manual configuration is needed:

- PWS for Distribution Planner

- PWS for Response Planner

- PWS for Shelf Life Planning

- PWS for Transportation Load Build (part of SAP7F with 2308)

If you are using SAPIBP1 as a base, you can use the following PWS:

- PWS for Footprint Analysis

- PWS for Global Demand Planner

- PWS for Inventory Planner (new with 2308)

Copy sample planning area SAP7F

PWS for Inventory Planner

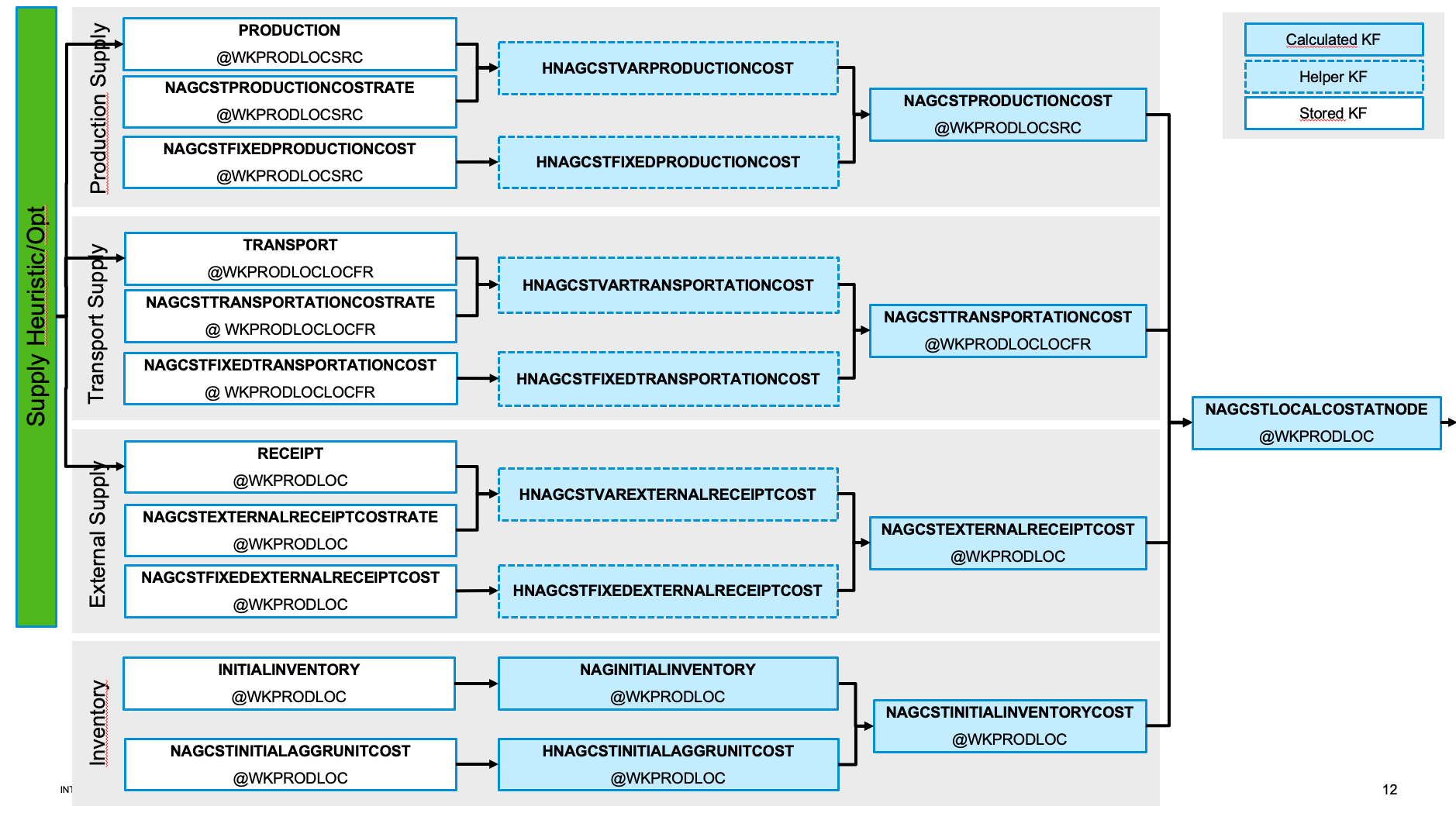

Cost rollup

The solution process IBP for sales and operations – supply review – heuristic has been enhanced with a cost rollup example. The new Network Aggregation operator calculates the unit cost of a product at a location and period by rolling-up cost incurred at various places in the upstream supply chain. Examples of such costs are transportation, production, inventory maintenance, and components. The results of the operator help to estimate the margin and profitability at a granular level of customer / product / location. You can calculate the contribution of various cost components like transport, production, and inventory to the unit cost of a finished product.

Excel Planning View (Aggregated Unit Costs)

Enhancements and changes for Sample Model SAPIBP1

- New key figures for cost rollup (around 30)

As explained above, we introduced the new Network Aggregation Operator application job. To run the operator, the SAPIBP1 sample planning area has been enhanced with exemplary key figures and cost rollup profiles.

Dependencies of new key figures for cost rollup

- New key figures for sales and marketing planning (integration to SAP Analytics Cloud - Commercial Planning)

To integrate marketing and sales spends from SAP Analytics Cloud, two integration key figures have been added. If you use this integration, ensure that a value is maintained for the CUSTCOUNTRY attribute of the IBPCUSTOMER master data type for all records for which the integration is performed.

Do you want to access the new content via SAP Signavio Process Navigator? Here you find everything you need.

Do you want to learn more about the usage of SAP Signavio Process Navigator? Please check out this short video.

- SAP Managed Tags:

- SAP Integrated Business Planning for Supply Chain

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

39 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- SAP IBP Real-Time Integration: Empowering Businesses for Smarter, Faster Decisions in Supply Chain Management Blogs by SAP

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 |