- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- SAP Asset Performance Management – Recommendation ...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member35

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-03-2023

8:38 AM

The SAP Asset Performance Management helps in developing maintenance strategies considering critical failure with the help of standard reliability methodologies such as Reliability Centered Maintenance (RCM), Failure Modes Effects Analysis (FMEA), etc., and in recommending mitigation actions.

For more details on Asset Strategy, please refer to the Asset Strategy Overview blog.

This blog will cover the SAP APM feature, Recommendation Workbench, which is used for centrally managing such recommendations.

When conducting RCM, FMEA or Strategy assessment for classes, it is essential to review and manage the recommendations that emerge from the assessment process.

In SAP Asset Performance Management, the Recommendation Workbench enables reliability engineers to create, review, manage and release recommendations for building asset strategies.

These strategies can be developed either for individual assets within the system or for multiple assets within a single strategy recommendation.

The recommendations released by the reliability engineer from recommendation workbench are typically implemented by the maintenance planner or team responsible for executing maintenance activities. The recommendations are implemented as maintenance rules, task lists and maintenance plans to generate actionable work orders or tasks assigned to the appropriate maintenance personnel.

In SAP Asset Performance Management, the recommended tasks broadly fall into two main categories: Maintenance task and Improvement activity. The maintenance activity can be either Proactive maintenance type or Reactive maintenance type. Therefore, the Recommendation supports the following types.

Proactive maintenance strategy enables the prevention of asset failure or breakdown through the implementation of preventive and predictive measures. The proactive maintenance type supports the following subtypes.

Reactive maintenance strategy, also known as corrective or breakdown maintenance, refers to repairs performed after equipment has broken down in order to return it to normal operational condition.

Activities that involve technical, administrative, and managerial actions (…activities like training, design change/ product change, process change, regulatory change, based on input from industry/experience, or to capture spares requirements etc., The one-off changes or tasks are created as improvement recommendation. In any industry, not all recommended tasks point to a maintenance plan or task list in execution system, these actions or tasks are captured as improvement recommendations.

Let us first understand the recommendation lifecycle before delving into recommendation creation. The recommendation must go through the following statuses in the recommendation workbench.

Note: The recommendation consolidation and implementation feature are upcoming subjects and will not be covered in this blog.

Now, to highlight the recommendation workbench features, let us create a recommendation without assessment (a standalone recommendation) from recommendation workbench.

Choose the recommendation workbench tile from the SAP Asset Performance Management Fiori launchpad

Next click on “Create” and fill the new Recommendation creation dialog with the necessary information.

Once created successfully, the object page loads. One can maintain the general data details like Cycle, Maintenance Activity Type, Recommendation Notes etc., and can save the recommendation.

To change the recommendation status, use “Change Status” button and to delete the recommendation use the “Manage” button.

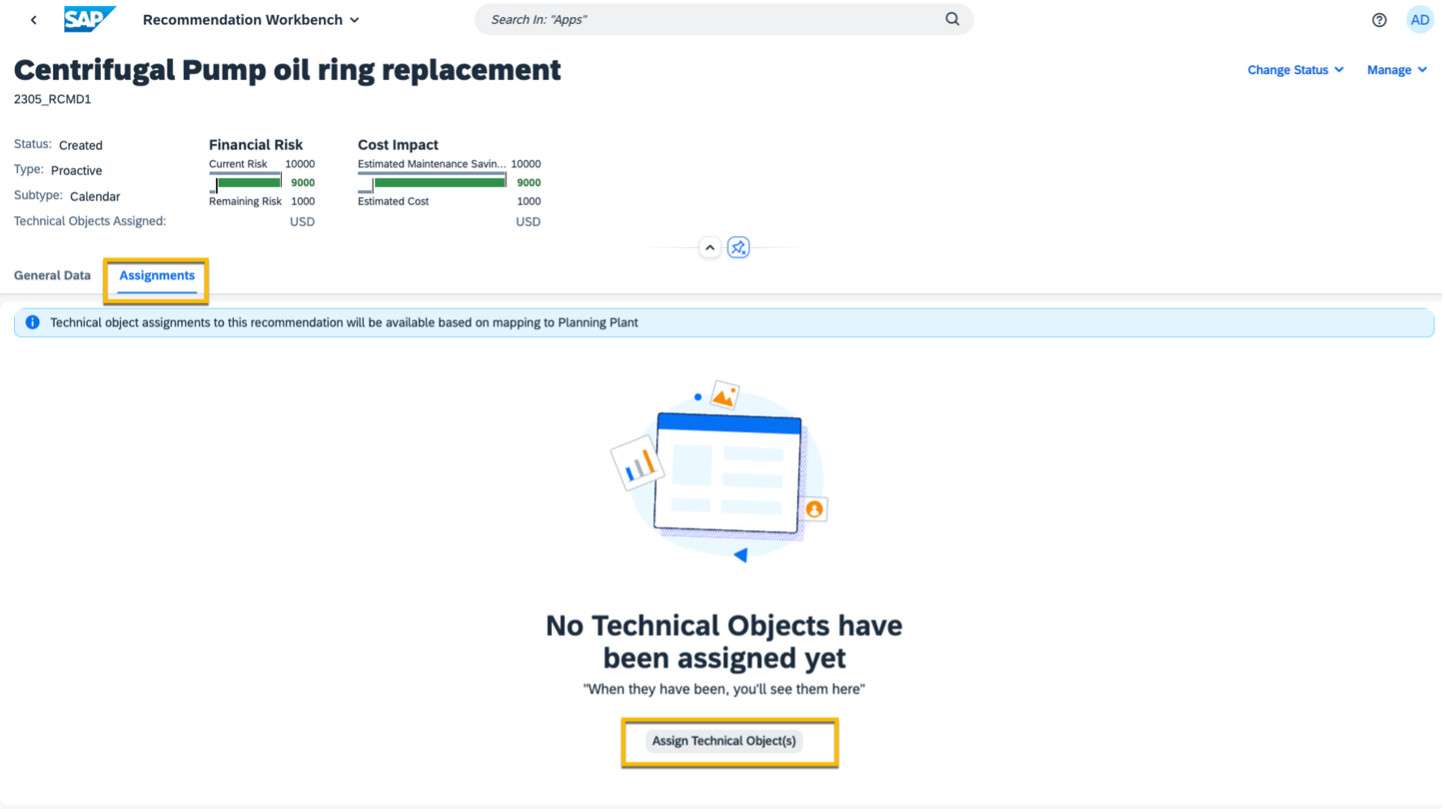

Next to assign technical objects to recommendation, go to “Assignments” section. Select the Assign Technical Objects button.

The Select Technical Objects window appears. The Technical Object count is displayed along with a list of technical objects.

Note: The assignment of the technical object to this recommendation is done based on the planning plant that is maintained in the recommendation.

Select the required technical object to be assigned and choose “OK”.

Once the recommendation is completed and reviewed, the recommendation can be sent to the "Released" status for implementation.

Now, let's explore how to mitigate the risk by creating recommendations for the failure modes identified through the RCM study.

To perform RCM study, refer to the RCM blog. After generating the failure data hierarchy, the recommendations can be created based on the failure data analysis and consequence evaluation done in the RCM assessment.

Click on “Create” after maintaining the relevant failure mechanisms, causes and failure effects for each failure mode.

The newly created recommendation appears in the recommendation section.

Click on the recommendation record to navigate to the recommendation object page. One can maintain the general data details like Cycle, Maintenance Activity Type, Recommendation Notes etc., and can save the recommendation.

Goto the failure data section, to the view the failure data hierarchy

Please refer the following SAP help document for further information on the Recommendation application in SAP Asset Performance Management solution

https://help.sap.com/docs/SAP_APM/1bb12075258a41e1a024d28a6ddfe246/578cf2567a454abbbc987a729fba24d8....

For more details on Asset Strategy, please refer to the Asset Strategy Overview blog.

This blog will cover the SAP APM feature, Recommendation Workbench, which is used for centrally managing such recommendations.

Picture 1: Sources of Recommendation in APM

When conducting RCM, FMEA or Strategy assessment for classes, it is essential to review and manage the recommendations that emerge from the assessment process.

In SAP Asset Performance Management, the Recommendation Workbench enables reliability engineers to create, review, manage and release recommendations for building asset strategies.

These strategies can be developed either for individual assets within the system or for multiple assets within a single strategy recommendation.

The recommendations released by the reliability engineer from recommendation workbench are typically implemented by the maintenance planner or team responsible for executing maintenance activities. The recommendations are implemented as maintenance rules, task lists and maintenance plans to generate actionable work orders or tasks assigned to the appropriate maintenance personnel.

Recommendation types

In SAP Asset Performance Management, the recommended tasks broadly fall into two main categories: Maintenance task and Improvement activity. The maintenance activity can be either Proactive maintenance type or Reactive maintenance type. Therefore, the Recommendation supports the following types.

Proactive Maintenance Strategy

Proactive maintenance strategy enables the prevention of asset failure or breakdown through the implementation of preventive and predictive measures. The proactive maintenance type supports the following subtypes.

- Calendar: Recommendations are scheduled based on time intervals.

- Performance: Recommendations are scheduled based on asset usage or counter readings.

- Condition: Recommendations are based on threshold values determined by observing and measuring operating assets over time, using indicators and the maintenance rules engine. These recommendations aim to prevent potential failures at the earliest possible time.

Reactive Maintenance Strategy

Reactive maintenance strategy, also known as corrective or breakdown maintenance, refers to repairs performed after equipment has broken down in order to return it to normal operational condition.

Improvement Maintenance Strategy

Activities that involve technical, administrative, and managerial actions (…activities like training, design change/ product change, process change, regulatory change, based on input from industry/experience, or to capture spares requirements etc., The one-off changes or tasks are created as improvement recommendation. In any industry, not all recommended tasks point to a maintenance plan or task list in execution system, these actions or tasks are captured as improvement recommendations.

Life cycle of a Recommendation

Let us first understand the recommendation lifecycle before delving into recommendation creation. The recommendation must go through the following statuses in the recommendation workbench.

| Status | Description |

| Created | The status Created is set by the system when a recommendation object is created either through an assessment or directly without an assessment (standalone recommendation). You can delete an existing recommendation only with the status Created. The recommendation once processed cannot be deleted and therefore can be set to Rejected. |

| In Process | This is used to intimate that recommendation is In Process. In case of rework, the recommendation shall be sent to In Process. |

| For Review | The recommendation when detailed (complete) is changed from For Review to Ready for Release for future action. |

| On Hold | When there is a temporary pause or delay in processing the recommendation, it can be sent to On Hold status. The On Hold recommendations can be sent back for further processing to In Process or can be Rejected. |

| Rejected | The reason for rejection is captured. |

| Released | Finally, when the recommendation is completed and reviewed, from the recommendation workbench, the Recommendation is sent to Released for Implementation. |

Picture 2: Recommendation lifecycle

Note: The recommendation consolidation and implementation feature are upcoming subjects and will not be covered in this blog.

Prerequisites for using the Recommendation Workbench

- You must have the following roles assigned to your user in order to work on the Recommendation Workbench application.

- The following configuration objects are successfully replicated from the SAP ERP to SAP Asset Performance Management system

- Maintenance Activity Type

- Priority Type

- Unit of Measure

- Currency

Standalone Recommendation

Now, to highlight the recommendation workbench features, let us create a recommendation without assessment (a standalone recommendation) from recommendation workbench.

Choose the recommendation workbench tile from the SAP Asset Performance Management Fiori launchpad

Next click on “Create” and fill the new Recommendation creation dialog with the necessary information.

Once created successfully, the object page loads. One can maintain the general data details like Cycle, Maintenance Activity Type, Recommendation Notes etc., and can save the recommendation.

To change the recommendation status, use “Change Status” button and to delete the recommendation use the “Manage” button.

Next to assign technical objects to recommendation, go to “Assignments” section. Select the Assign Technical Objects button.

The Select Technical Objects window appears. The Technical Object count is displayed along with a list of technical objects.

Note: The assignment of the technical object to this recommendation is done based on the planning plant that is maintained in the recommendation.

Select the required technical object to be assigned and choose “OK”.

Once the recommendation is completed and reviewed, the recommendation can be sent to the "Released" status for implementation.

Recommendation created from RCM assessment

Now, let's explore how to mitigate the risk by creating recommendations for the failure modes identified through the RCM study.

To perform RCM study, refer to the RCM blog. After generating the failure data hierarchy, the recommendations can be created based on the failure data analysis and consequence evaluation done in the RCM assessment.

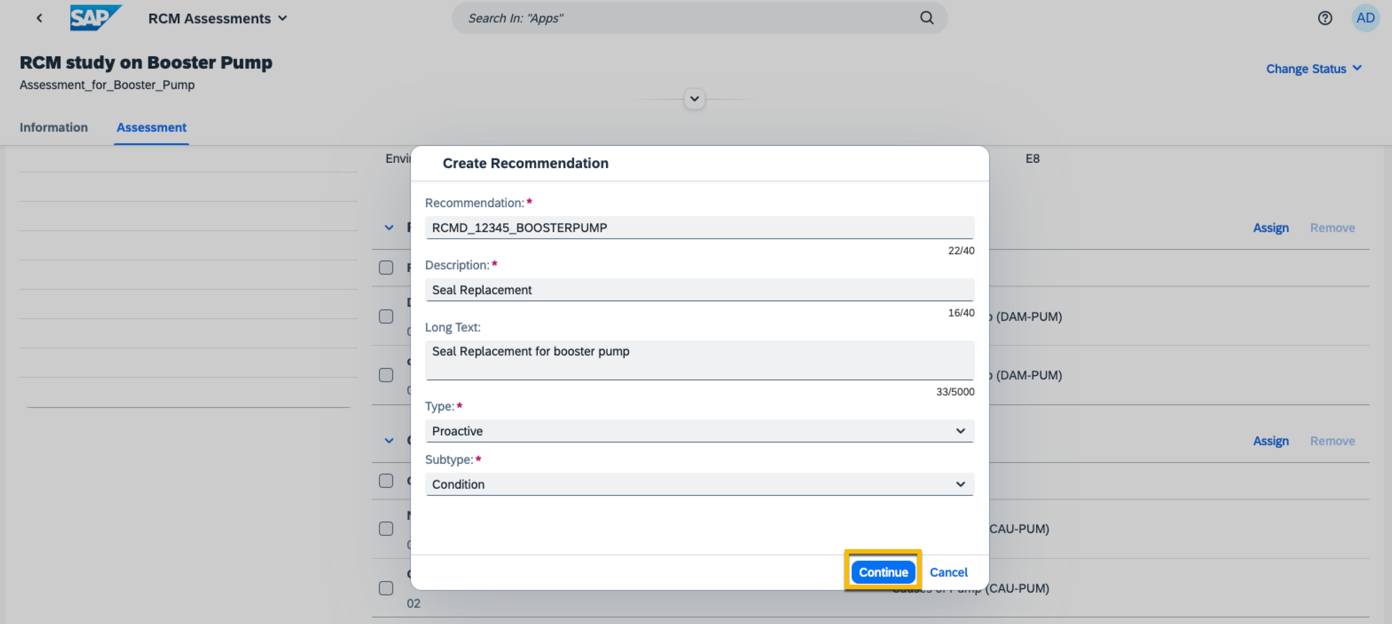

In RCM assessment, in recommendation section, click on “Create” and fill the new Recommendation creation dialog with the necessary information.

Click on “Create” after maintaining the relevant failure mechanisms, causes and failure effects for each failure mode.

The newly created recommendation appears in the recommendation section.

Click on the recommendation record to navigate to the recommendation object page. One can maintain the general data details like Cycle, Maintenance Activity Type, Recommendation Notes etc., and can save the recommendation.

Goto the failure data section, to the view the failure data hierarchy

Please refer the following SAP help document for further information on the Recommendation application in SAP Asset Performance Management solution

https://help.sap.com/docs/SAP_APM/1bb12075258a41e1a024d28a6ddfe246/578cf2567a454abbbc987a729fba24d8....

- SAP Managed Tags:

- SAP Asset Strategy and Performance Management,

- SAP Asset Performance Management

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

39 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- SAP Asset Performance Management Embedding Cumulocity IoT to Drive Innovations in IoT and AI in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- What's new with Collaborative Maintenance? in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 6 | |

| 5 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |