- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- MRO Spare Parts & Labor Resource Planning with SAP...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Employee

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-12-2023

10:14 AM

Last year we shared our MRO strategy and introduced the first releases for SAP IBP for MRO Spare Parts Planning and labor Resource planning, which seeks to align and integrate the planning functions key to Asset Maintenance including Supply Chain Planning. A solution resulting SAP´s global co-innovation initiative together with 100+ interested customers.

Continuous development in IBP MRO is key to making our customers a success. In case you missed it, you can find the last release highlights blog and the customer initiative in those links.

Today, I would like to share the development highlights for the latest 2308 releases shipped in August and the 2305 Release shipped in May. We focus on four key pillars, Out of the box Integration with Project Systems, MRO inventory operator, including Mean Time Between Failure (MTBF), a dedicated sample planning area ‘SAP9’ for MRO and Introducing MRO Best Practice content.

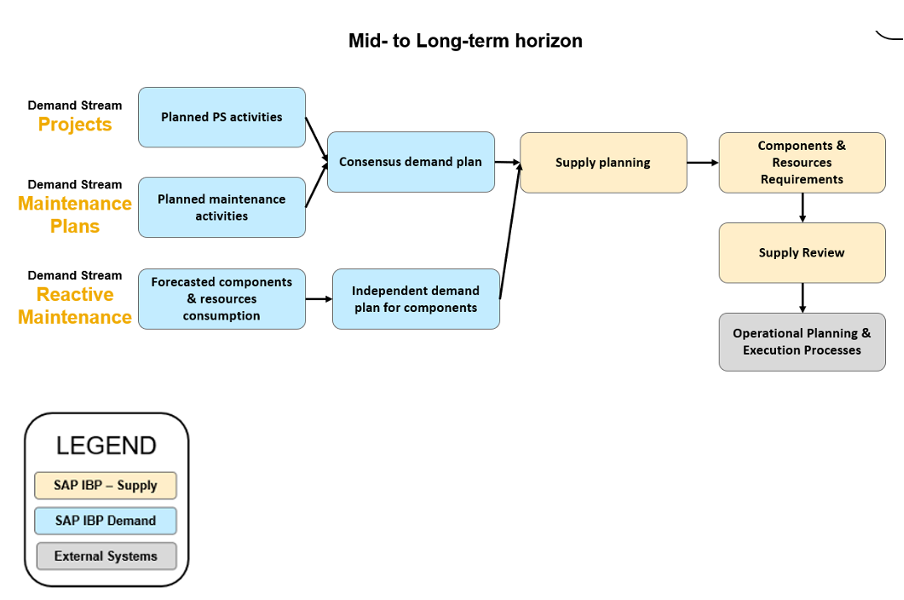

In case of the installation of new Assets, Machines or plants, several customers in the Asset intensive space, uses SAP Project Systems. With the latest release of 2308 shipped in August, IBP MRO is now able to consider Parts and labor resource demands arising from those projects and combine it with the demand that comes from Plant Maintenance solutions. This is possible with standard integration content between IBP MRO and SAP Project Systems.

Now customers can combine both demand streams from Plant Maintenance intergration & from Project Systems integration combined!! Data from Workbench Structures (WBS) focused on Projects are considered, which includes attributes about the assets, parts/materials, start/end dates and labor required to perform the project. This information can be later used via the infinite heuristics and generate a purchase plan.

IBP for MRO is now able to provide more accurate inventory parameters for items with intermittent demand which helps reduce inventory holding costs and improves asset uptime.

The MRO Inventory Planning Operator available with the 2308 Release, calculates inventory parameters such as Safety Stock, Reorder Point and Target Inventory Position for parts used in Maintenance, Repair, and Operations.

The operator uses the Poisson distribution which is effective in determining inventory parameters for parts with sporadic demand.

A key highlight is that the new MRO Inventory Operator now supports Mean Time Between Failure calculation (MTBF). This is specifically relevant in case there is not enough MRO parts historical consumption data. It can be run at an aggregate level to support location or product pooling.

The manage Forecast Automation Profiles app can be used to classify whether demand is: Intermittent (slow-moving), Continuous (fast-moving), or in case there is Insufficient Data or no data. This is a critical step in determining how the part can be best forecasted and how the inventory will be planned. This is also relevant for Criticality based target service level determination that accounts for qualitative and quantitative factors, which we plan to further automate in subsequent releases.

To be able to streamline and simplify configuration with end-to-end MRO business processes, we shipped a dedicated MRO sample planning area available with the 2305 Release. ‘SAP9’ sample planning area helps to jump-start implementations and provide a platform for upcoming features and functionality by copying it from SAP IBP’s Sample Model Entities App. Additionally, it improves usability using Part, Maintenance Plan, and Asset master data types.

Capabilities

We introduced SAP Best practice content for IBP MRO with the 2308 Release to allow customers & partners to run an end to end MRO planning process with provided test data. The content includes all MRO-relevant Master data and Key figures, covering Demand, Inventory and Supply planning processes, available in the above-mentioned base planning area SAP9.

Additionally, it includes Microsoft Excel Planning views that cover MRO planning process and provides tools to prepare the data for the planning process: segmentation operators, time-series analysis.

Additional details and further information can be found here.

We plan to continue developing functionality and enhancements in the upcoming releases. For instance, we are working to add a standard operator for Criticality based Target Service Level determination to our sample planning area. We also continue to iteratively enhance the MRO Inventory Planning Operator. Additionally, we plan to introduce an early concept around Rotables Planning and designs for Synchronized Planning for MRO.

We continue to our development to provide a true Synchronized Planning for MRO , aligning all relevant plans and planners together.

Follow Diaa on LinkedIn or X/Twitter

Relevant Links:

Relevant Blogs:

Continuous development in IBP MRO is key to making our customers a success. In case you missed it, you can find the last release highlights blog and the customer initiative in those links.

Today, I would like to share the development highlights for the latest 2308 releases shipped in August and the 2305 Release shipped in May. We focus on four key pillars, Out of the box Integration with Project Systems, MRO inventory operator, including Mean Time Between Failure (MTBF), a dedicated sample planning area ‘SAP9’ for MRO and Introducing MRO Best Practice content.

Out of the box Integration content with Project Systems

In case of the installation of new Assets, Machines or plants, several customers in the Asset intensive space, uses SAP Project Systems. With the latest release of 2308 shipped in August, IBP MRO is now able to consider Parts and labor resource demands arising from those projects and combine it with the demand that comes from Plant Maintenance solutions. This is possible with standard integration content between IBP MRO and SAP Project Systems.

Now customers can combine both demand streams from Plant Maintenance intergration & from Project Systems integration combined!! Data from Workbench Structures (WBS) focused on Projects are considered, which includes attributes about the assets, parts/materials, start/end dates and labor required to perform the project. This information can be later used via the infinite heuristics and generate a purchase plan.

MRO Inventory Operator incl. Mean Time Between Failures (MTBF)

IBP for MRO is now able to provide more accurate inventory parameters for items with intermittent demand which helps reduce inventory holding costs and improves asset uptime.

The MRO Inventory Planning Operator available with the 2308 Release, calculates inventory parameters such as Safety Stock, Reorder Point and Target Inventory Position for parts used in Maintenance, Repair, and Operations.

The operator uses the Poisson distribution which is effective in determining inventory parameters for parts with sporadic demand.

A key highlight is that the new MRO Inventory Operator now supports Mean Time Between Failure calculation (MTBF). This is specifically relevant in case there is not enough MRO parts historical consumption data. It can be run at an aggregate level to support location or product pooling.

The manage Forecast Automation Profiles app can be used to classify whether demand is: Intermittent (slow-moving), Continuous (fast-moving), or in case there is Insufficient Data or no data. This is a critical step in determining how the part can be best forecasted and how the inventory will be planned. This is also relevant for Criticality based target service level determination that accounts for qualitative and quantitative factors, which we plan to further automate in subsequent releases.

Dedicated Sample Planning Area SAP9 for MRO

To be able to streamline and simplify configuration with end-to-end MRO business processes, we shipped a dedicated MRO sample planning area available with the 2305 Release. ‘SAP9’ sample planning area helps to jump-start implementations and provide a platform for upcoming features and functionality by copying it from SAP IBP’s Sample Model Entities App. Additionally, it improves usability using Part, Maintenance Plan, and Asset master data types.

Capabilities

- Provides out-of-the-box planning operators used to support MRO business processes

- MRO specific MDTs provide additional flexibility for modeling various maintenance, repair and operations use cases

- MRO specific key figures are provided to support forecasting and supply planning related to corrective and preventative maintenance

- MRO specific data model that supports determining of the Criticality based Target Service Level that accounts for qualitative and quantitative factors

Best Practice content

We introduced SAP Best practice content for IBP MRO with the 2308 Release to allow customers & partners to run an end to end MRO planning process with provided test data. The content includes all MRO-relevant Master data and Key figures, covering Demand, Inventory and Supply planning processes, available in the above-mentioned base planning area SAP9.

Additionally, it includes Microsoft Excel Planning views that cover MRO planning process and provides tools to prepare the data for the planning process: segmentation operators, time-series analysis.

Additional details and further information can be found here.

What’s Planned for the future!

We plan to continue developing functionality and enhancements in the upcoming releases. For instance, we are working to add a standard operator for Criticality based Target Service Level determination to our sample planning area. We also continue to iteratively enhance the MRO Inventory Planning Operator. Additionally, we plan to introduce an early concept around Rotables Planning and designs for Synchronized Planning for MRO.

We continue to our development to provide a true Synchronized Planning for MRO , aligning all relevant plans and planners together.

Follow Diaa on LinkedIn or X/Twitter

Relevant Links:

- Maintenance, Repair, and Operations process in IBP: Help page

- MRO Inventory Planning Operator in IBP: Help page

- Project System Master data Extractors for ECC: Collecting and Transforming Master Data for Maintenance, Repair and Operations Solution from Project System

- CI-DS Template for the Project System Master data: IBP_MRO_SAP9_PS_MD_S4_ERP_AddOn | SAP Help Portal

- SAP Note 3137241 with Project System objects creation guide: https://launchpad.support.sap.com/#/notes/3137241

- Demo for IBP MRO solution

Relevant Blogs:

- Best Practice Blog by Ina

- 2305 highlights Blog by Thomas Klemm

- 2308 highlights Blog by Thomas Klemm

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

39 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |