- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- EWM Cycle Counting Physical Inventory Procedure

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

The traditional method of conducting a physical inventory, where operations come to a standstill for a complete stocktake, is increasingly being replaced by more agile and frequent approaches. SAP EWM's Cycle Counting is one such approach that enables organizations to achieve real-time visibility into their inventory levels without disrupting daily activities, also considering product-specific inventory requirements, which can require periodic physical inventories in shorter periods of time.

In this SAP Blog, I will be explaining in detail the physical inventory procedure Cycle Counting in SAP EWM. The needed configuration and a demo in a test system is also covered. I hope you all enjoy 😉

1. Introduction

While the annual physical inventory procedures happen in yearly basis, the Cycle Counting consists in a method of inventory that can happen several times within a single year with predefined periods that can change from product to product depending on the defined master data of the materials. This procedure is also different of an ad-hoc physical inventory that can be executed at any time without period validation.

2. Required Configuration

2.1 Define Cycle Counting Indicators

The first step is to configure the cycle counting intervals available at warehouse level. Here, for every warehouse number, it's required to define the cycle counting indicator, which will be later defined at material level. Each indicator defined has an interval in working days between each cycle count and the buffer time in working days.

This configuration is available in the SPRO path SCM Extended Warehouse Management -> Extended Warehouse Management -> Internal Warehouse Processes -> Physical Inventory -> Warehouse-Number-Specific Settings -> Configure Cycle Counting.

Configure Cycle Counting Indicators

The Cycle Counting indicator has an interval + a buffer time, which represents the length of time allowed after the expiration of a cycle counting interval before you must cycle count a product again.

CC Interval + buffer

2.2 Assign Cycle Counting indicator to material

The Cycle Counting Indicator assigned to the materials can be displayed or changed by accessing the material in /SCWM/MAT1 transaction, in the "Whse Data" tab:

CC Indicator in the Product Master Data

Optionally, this can be determined automatically during ABC Analysis. The ABC analysis can be executed by running the transaction /SCWM/ABC as shown below:

CC Indicator update via ABC Analysis

The % and criteria for defining the ABC class can be changed according to the business needs. The execution shows the proposed update to CC Indicator:

Proposed CC Indicator update from ABC Analysis

By clicking on "Save Selected Updates", the proposed CC indicator is saved automatically to the product master data all selected materials.

3. Understanding /SCWM/PI_CC_CREATE transaction

The next step is to run the CC physical inventory procedure for the warehouse. This can be done using the transaction code /SCWM/PI_CC_CREATE or via report /SCWM/PI_CC_CREATE in background (e.g., job processing with variant). The first step is to input the selection criteria and evaluate the proposed physical inventory documents. The screenshot below shows the face of the transaction:

/SCWM/PI_CC_CREATE transaction

Regarding each selection criteria available:

- Location Data

Warehouse Number, Activity Area, Storage Bin, Storage Type and Storage Section: location of the stock to be evaluated.

Maximum Number of Items: number of lines in the report proposal (number of Physical Documents proposed for creation).

- Product Data

Product, Owner, Party Entitled to Dispose, Cycle Counting Indicator: Stock selection criteria.

Maximum Number of Products: Number of different products in the report proposal.

- Physical Inventory Data

Inventory in Period: This indicates the period to be evaluated for Physical Inventory document creation.

Count Date: Planned count date to be inserted in the created PI documents.

Include Inventoried Objects: This selection parameter can be used to include already counted stocks in a physical inventory area, but this is valid only if the concerned product is not completely counted in the AA. For example, let's say that there are 3 different stocks for the product A in a particular PI area:

Storage bin 1 -> 10EA posted with an HL PI document.

Storage bin 2 -> 10EA posted with an AS PI document.

Storage bin 3 -> not counted yet (10EA pending).

Now, if you create a CC PI document without the indicator set, the system will propose the storage bin 3 only. In the other hand, if you create a Cycle Counting PI document and mark the flag "Include Already-Inventoried Objects", the system will propose all the 3 storage bins. If the 3 bins are completely counted already (full quantity of the product in the activity area), and the completeness check is already set for the product, e.g., via report /SCWM/PI_COMPL_CHECK, then this flag has no impact.

Active PI Document: Create Active or Inactive Physical Inventory Document.

Freeze Book Inventory: If the parameter is set, the book inventory lines are determined during document creation. Otherwise, the book inventory lines are determined at the moment when the count is entered.

Blocking Indicator: If the parameter is set, the entire storage bin (storage-bin-specific physical inventory ) or a product (product-specific physical inventory) in a storage bin is blocked for further movements.

Reason: Reason code for the physical inventory, which may be needed in ERP side depending on the configuration, as explained in the SAP KBA 2512992 - "MI07 - 'M7 325 - A reason has to be entered for movement type &'".

Reference: Any information that you need to reference in the PI document to be created.

Maximum Document Items: Maximum Number of Items in Phys. Inventory Document.

- Processing Mode

Simulation Mode: No COMMIT will be triggered by the report execution in background mode, there is no impact for the execution in the UI using transaction /SCWM/PI_CC_CREATE.

Background Mode: This flag can be used for execution in background, so the report result immediately create the CC Physical Inventory documents, unless the "Simulation Mode" is set.

Explanation Mode: This flag will only show general information about the identified stocks in relation to cycle counting procedure, as, for example, the CC indicators assigned to every material, intervals in days, stock existence per Activity Area, last counting date, next counting date. The save and simulate buttons are removed from the report result screen:

Cycle counting - explanation mode

4. Running EWM Cycle Counting procedure

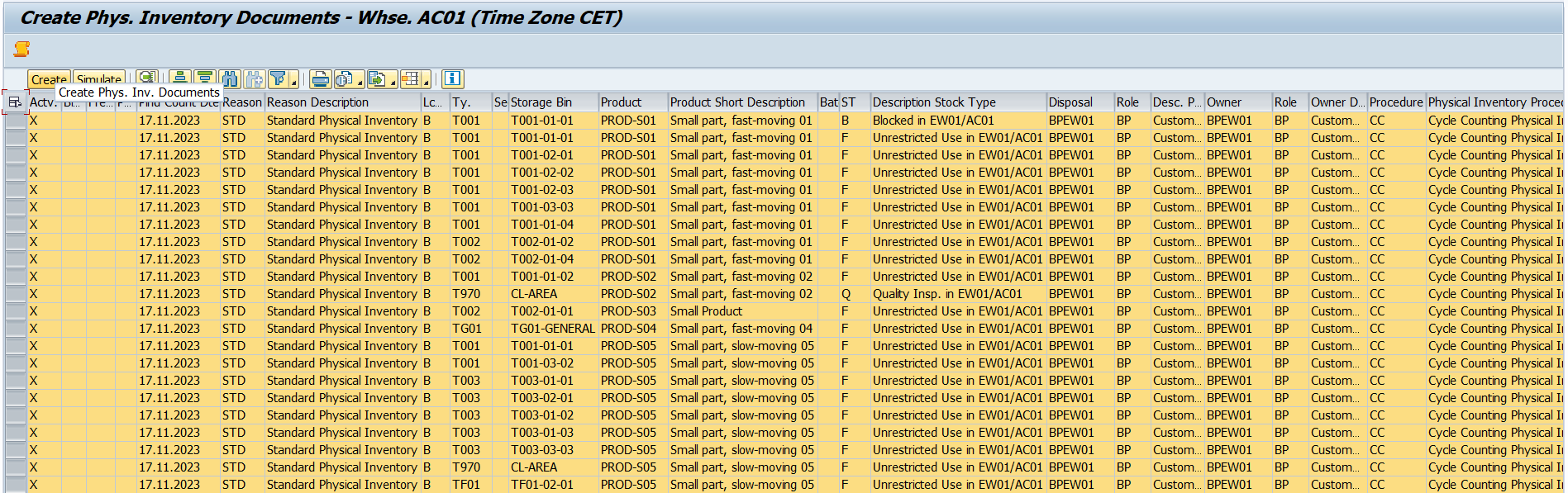

By running the report /SCWM/PI_CC_CREATE with proper selection criteria, the following screen appears:

Cycle counting report result

Upon clicking the "Create" button, the system shows the physical inventory documents created:

Created Physical Inventory documents

In this example, 6 PI documents were created. Now, the counting steps and posting steps are the same of any other physical inventory document. For this case, let's use the transaction /SCWM/PI_COUNTLIST to enter the results in mass using SAP GUI:

/SCWM/PI_COUNTLIST transaction

The /SCWM/PI_COUNTLIST is just one of the methods that SAP EWM offers for counting. The counting can be done in RFUI screens using handheld devices or directly in /SCWM/PI_PROCESS transaction, for example. Usually /SCWM/PI_COUNTLIST is a better option for paper-based counting.

Now, after counting and recounting steps (if required), it's necessary to post the differences to EWM with /SCWM/PI_PROCESS transaction and adjust MM stocks with /SCWM/DIFF_ANALYZER transaction.

Post step in /SCWM/PI_PROCESS transaction

Post step in /SCWM/DIFF_ANALYZER transaction

By the end of the process, the stocks are updated in ERP and EWM after the counting steps, which were generated based on cycles indicators defined for every product in the warehouse.

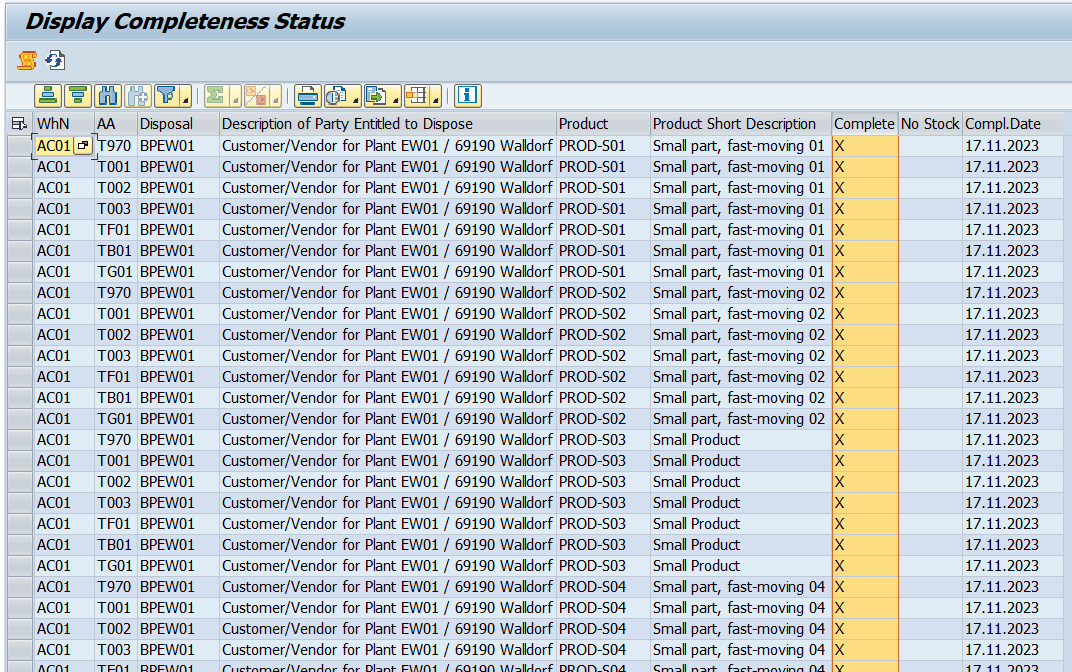

The report SCWM/PI_COMPL_CHECK can be used to display and update the completeness indicator for the stocks, so they will not be considered in the next round of the cycle counting process, unless they already lie outside the defined cycle counting interval by that moment.

/SCWM/PI_COMPL_CHECK transaction

Completeness check result

5. Conclusion

This blog post presented the details of the Cycle Counting physical inventory procedure in SAP EWM, from the necessary configuration to the execution of the procedure in a test sytem.

The configuration process involves defining cycle counting indicators at the warehouse level and assigning them to materials based on predefined criteria. The flexibility of adjusting intervals and criteria allows businesses to tailor the process to their specific needs, making it a versatile solution for diverse inventory management requirements.

The understanding of the /SCWM/PI_CC_CREATE transaction highlighted the operational aspects of running the Cycle Counting procedure. By utilizing this transaction, organizations can efficiently create and manage Physical Inventory documents, ensuring accuracy and timeliness in their inventory management practices.

The actual execution of the Cycle Counting procedure involves selecting criteria such as location, product data, and physical inventory data. The processing modes, including simulation and background modes, offer flexibility in adapting the procedure to different operational scenarios.

After the counting steps are completed, the follow-up steps involve updating stocks in both ERP and EWM systems. The completeness check ensures that stocks are disregarded in cycle counting processes if they were already inventoried in the current period for a given material.

In conclusion, the adoption of SAP EWM's Cycle Counting methodology presents a compelling solution for businesses seeking precision and efficiency in managing their inventories. The ability to tailor the process to specific business requirements, coupled with the real-time visibility it provides, makes it a valuable asset for companies continuously evaluating and optimizing their stock levels throughout the year.

6. FAQ and References

Lot of Frequently Asked Questions related to physical inventory are covered in the SAP Note 3273494 - "FAQ: Physical inventory in EWM".

References:

SAP Help | Physical Inventory

2993430 - "SAP S/4HANA EWM Best Practice Content"

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- EWM - Goods Movement,

- MM Inventory Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

39 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

- Inventory Procedure With a Modified SKU in Supply Chain Management Q&A

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- Retail: physical inventory with MDE in Supply Chain Management Q&A

- SAP EWM FAQ Series: How to setup monitoring and alerts in Supply Chain Management Blogs by SAP

- EWM blind cycle count by bin (not product and/or batch) in Supply Chain Management Q&A

| User | Count |

|---|---|

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |