- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP-EWM-Threshold addition field in Storage type .

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ewmbee786

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-23-2023

12:15 PM

Introduction :

Real time issue from warehouse:

One of the warehouse manager found that due to split during put away allowed in the storage type system split small qty of multiple tasks for one pallet. To put away this one pallet qty into multiple bins forklift operator is taking much time in put away. It is leading to warehouse inefficiency to manage resources in inbound operations.

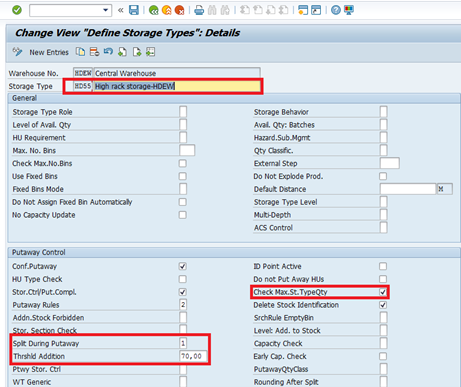

To curb the above situation Warehouse manager has decided, if any storage bin is occupied with greater or equal to 70% of its capacity then system should not split during put away to this bin. (NO warehouse task should be created to this bin since it reaches to the threshold percentage)

So that we can avoid splitting of small qty warehouse tasks for put away. Operations efficiency will increase in inbound side.

Configuration steps:

TESTING

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> DEFINE STORAGE TYPE

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> DEFINE STORAGE SECTION

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> STORAGE BINS -> DEFINE STORAGE BIN TYPES

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> ACTIVITY AREAS -> GENERATE ACTIVITY AREA FROM STORAGE TYPE

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK -> DEFINE WAREHOUSE PROCESS TYPE

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK ->DEFINE CONTROL INDICATORS FOR DETERMINING WAREHOUSE PROCESS TYPES

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK -> DETERMINE WAREHOUSE PROCESS TYPE

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> DEFINE STORAGE TYPE SEARCH SEQUENCE FOR PUTAWAY

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> ASSIGN STORAGE TYPES TO STORAGE TYPE SEARCH SEQUENCE

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> DEFINE PROCESS TYPE INDICATOR

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> SPECIFY STORAGE TYPE SEARCH SEQUENCE FOR PUTAWAY.

In above screen shot you can clearly see first 3 bins are having 90 KGs in each now as per our configurations of threshold to addition -70% system won’t create WT for first 3 bins. System will skip the WT creation even though split during put away tick is there; system will look for threshold to addition field value.

Create inbound delivery against to PO (VL31N)

Process the inbound delivery (/N/SCWM/PRDI)

Create put away task

Here you can see clearly system create the put away task for hd55-01-04 & hd55-01-07

Means system create the task for less than 70% stock bins. It happened due to threshold to addition field in storage type.

Confirm put away task and check the stock after confirmation.

Conclusion : System avoided split of WT to un necessary small qty tasks. Last two bins filled because first three bins exceeded the threshold qty.

Share and comment for better reach.

thanks

Rohela Khan.

Real time issue from warehouse:

One of the warehouse manager found that due to split during put away allowed in the storage type system split small qty of multiple tasks for one pallet. To put away this one pallet qty into multiple bins forklift operator is taking much time in put away. It is leading to warehouse inefficiency to manage resources in inbound operations.

To curb the above situation Warehouse manager has decided, if any storage bin is occupied with greater or equal to 70% of its capacity then system should not split during put away to this bin. (NO warehouse task should be created to this bin since it reaches to the threshold percentage)

So that we can avoid splitting of small qty warehouse tasks for put away. Operations efficiency will increase in inbound side.

Configuration steps:

- Define storage type (HD55)

- Define storage section- 0001

- Define storage bin type -(H9)

- Create few bin’s T. Code (/N/SCWM/LS01)

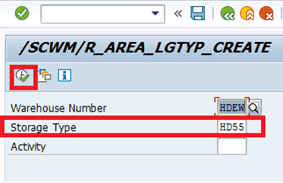

- Generate activity area

- Create storage bin sorting- Tcode: (/N/SCWM/SBST)

- Define warehouse process type. (HD55)

- Define process type determination indicator (PTDI: 55)

- Determine warehouse process type

- Define Storage Type Search Sequence for Put away (ST55)

- Assign Storage Types to Storage Type Search Sequence

- Define process type indicator (PA55)

- Specify storage type search sequence for put away.

TESTING

- Create purchase order (ME21N)

- Create inbound delivery against PO (VL31N)

- Process the inbound delivery (/N/SCWM/PRDI)

- Create Put away task

- Confirm put away task

- Define storage type (HD55)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> DEFINE STORAGE TYPE

1

- Define storage section

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> DEFINE STORAGE SECTION

2

- Define storage bin type (H9)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> STORAGE BINS -> DEFINE STORAGE BIN TYPES

3

- Create manual bin’s t. Code (/N/SCWM/LS01)

- Generate activity area

PATH: SPRO -> IMG -> SCM EWM -> EWM -> MASTER DATA -> ACTIVITY AREAS -> GENERATE ACTIVITY AREA FROM STORAGE TYPE

5

- Create storage bin sorting (/N/SCWM/SBST)

6

- Define warehouse process type. (HD55)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK -> DEFINE WAREHOUSE PROCESS TYPE

7

- Define process type determination indicator (PTDI : 55)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK ->DEFINE CONTROL INDICATORS FOR DETERMINING WAREHOUSE PROCESS TYPES

8

- Determine warehouse process type

PATH: SPRO -> IMG -> SCM EWM -> EWM -> CR0ESS PROCESS SETTING -> WAREHOUSE TASK -> DETERMINE WAREHOUSE PROCESS TYPE

9

- Define Storage Type Search Sequence for Put away (ST55)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> DEFINE STORAGE TYPE SEARCH SEQUENCE FOR PUTAWAY

10

- Assign Storage Types to Storage Type Search Sequence

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> ASSIGN STORAGE TYPES TO STORAGE TYPE SEARCH SEQUENCE

11

- Define process type indicator (PA55)

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> DEFINE PROCESS TYPE INDICATOR

12

- Specify storage type search sequence for put away.

PATH: SPRO -> IMG -> SCM EWM -> EWM -> GOODS RECIEPT PROCESS -> STRATEGIES -> SOTRAGE TYPE SEARCH -> SPECIFY STORAGE TYPE SEARCH SEQUENCE FOR PUTAWAY.

13

- Create material master (MM01)

- Maintain product master (/N/SCWM/MAT1)

15

16

17

- You can see available stock in the storage bin as below (/N/SCWM/MON)

18

In above screen shot you can clearly see first 3 bins are having 90 KGs in each now as per our configurations of threshold to addition -70% system won’t create WT for first 3 bins. System will skip the WT creation even though split during put away tick is there; system will look for threshold to addition field value.

- Create purchase order (ME21N)

20

Create inbound delivery against to PO (VL31N)

21

Process the inbound delivery (/N/SCWM/PRDI)

22

Create put away task

23

24

25

Here you can see clearly system create the put away task for hd55-01-04 & hd55-01-07

Means system create the task for less than 70% stock bins. It happened due to threshold to addition field in storage type.

Confirm put away task and check the stock after confirmation.

26

Conclusion : System avoided split of WT to un necessary small qty tasks. Last two bins filled because first three bins exceeded the threshold qty.

Share and comment for better reach.

thanks

Rohela Khan.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- Implementing Automated Storage of TM Attachments in the SAP Document Management System in Supply Chain Management Blogs by SAP

- handling unit it does not appear in the sampling worklist report in Supply Chain Management Q&A

- Advanced Shipping and Receiving Simplifying the Connectivity in Supply Chain Management Blogs by Members

- Preferred Alternative UoM for Warehouse Operation in EWM in Supply Chain Management Blogs by Members

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |