- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP-EWM -Deconsolidation through POSC.

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ewmbee786

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-05-2023

2:02 PM

SAP-EWM -POSC

Introduction:

Now a days most of the all-value-added services are being performed on the product in the warehouse before put away the products.

So, to execute the complex activities in the warehouse, we will follow Storage control processes.

Process oriented storage control is one of them.

Will see one POSC examples in inbound side with Unloading, deconsolidation and put away.

Configuration Steps:

1.1. Define external steps

1.2. Define storage process

1.3. Assign storage step process to storage process

1.4. Setup POSC

5.1. Define storage type search sequence

5.2. Assign storage type to storage type search sequence

5.3. Define put away control indicator

5,4. Specify storage type search sequence for putaway

Testing:

PATH: SPRO->REF IMG-> SCM EWM-> CROSS-PROCESS SETTINGS-> WAREHOUSE TASK-> DEFINE PROCESS ORIENTED STORAGE CONTROL

1.1. Define external steps

1.2. Define storage process

1.3. Assign storage process step to storage process

1.4. Setup POSC

We don’t enter AD03 step because, my put away will taken care by put away strategies.

PATH: SPRO-> REF IMG-> SCM EWM-> CROSS-PROCESS SETTINGS-> WAREHOUSE TASK-> DEFINE WAREHOUSE PROCESS TYPE

4. Determine warehouse process type

5.1. Define storage type search sequence

PATH: SPRO-> REF IMG-> SCM EWM->GOODS RECEIPT PROCESS-> STRATEGIES-> STORAGE TYPE SEARCH-> DEFINE STORAGE TYPE SEARCH SEQUENCE

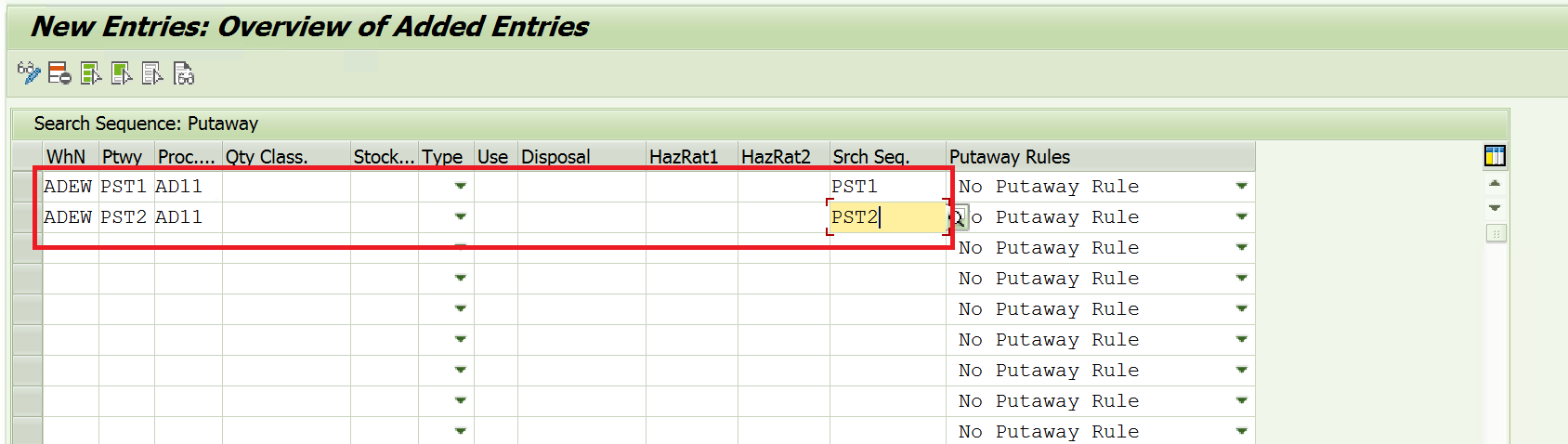

We will create two STSS for two products so that it can go into two different storage types.

5.2. Assign storage type to storage type search sequence.

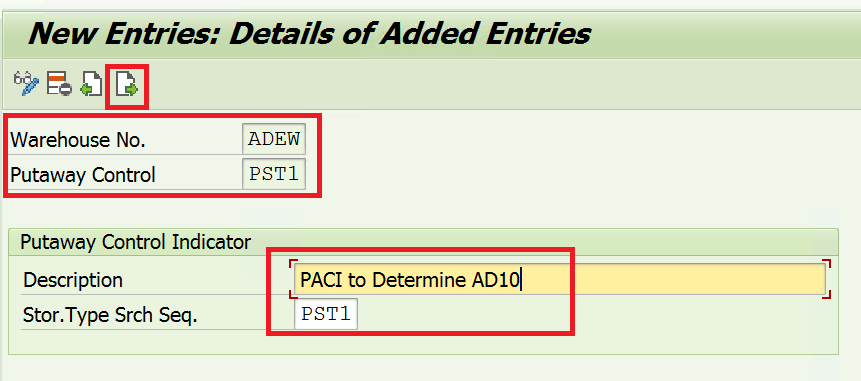

5.3. Define put away control indicator

5.4. Specify storage type search sequence for putaway

PATH: SPRO-> REF IMG-> SCM EWM-> EWM -> MASTER DATA-> WORK CENTER-> SPECIFY WORK CENTER LAYOUT

PATH: SPRO-> REF IMG-> SCM EWM-> EWM-> GOODS RECEIPT PROCESS>DECONSOLIDATION->DEFINE ATTRIBUTES OF DECONSOLIDATION

Enter the maximum number of WT for putaway HU and also in Deconsolidation HU.

9.2. Specify deconsolidation station

9.3. Assign number range intervals to consolidation groups

TESTING

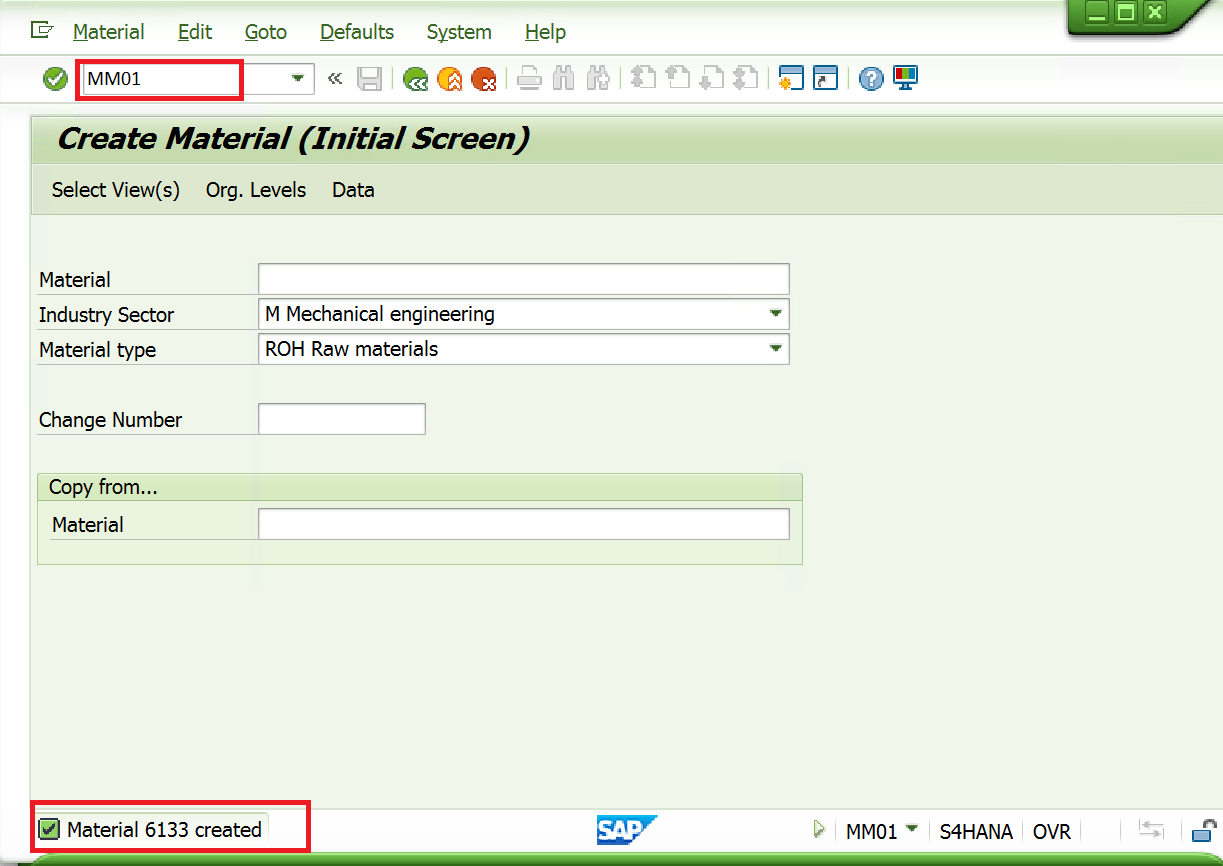

Material Master--MM01-6133,6134

Material-6133

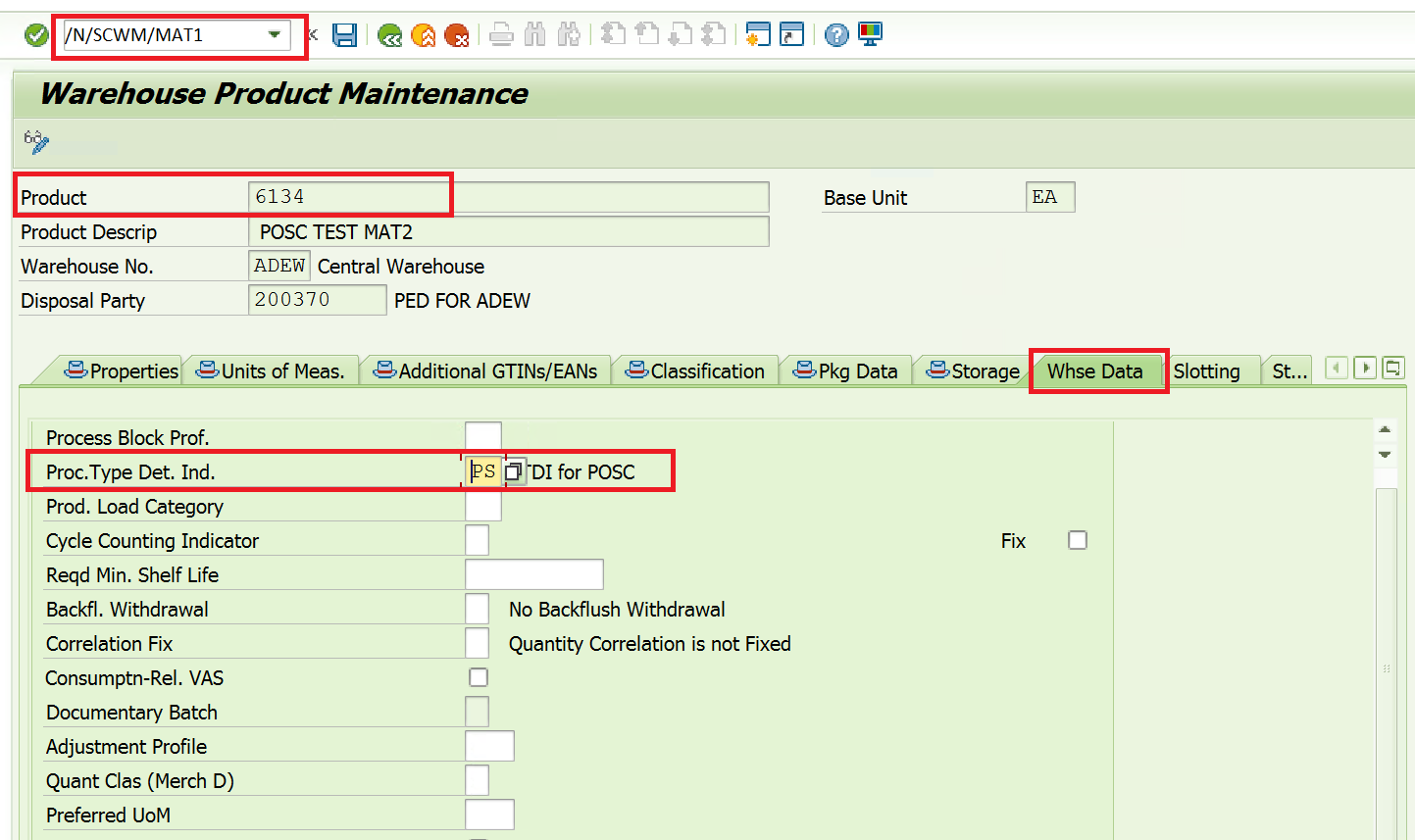

Material-6134

Product-6133

Product-6134

In one HU we are going to pack two materials. (Assume these two products came in one HU)

Select the packaging material and two materials and click on Pack icon, it is distributed to EWM in 1 Pallet with two materials.

5.1. Create the unloading warehouse task

From the below picture we can observe that System determines storage process which is assigned to WPT

Go to Monitor and check the warehouse order in Inbound delivery

PATH: Inbound delivery->Enter the Inbound delivery no-> Execute-> Select the line item and click on Inbound delivery item Button

Once we confirm the unloading task system will create 3 more tasks, two are in waiting status -B, one more task for move the HU to Deconsolidation work center.

once deconsolidation process completed then it will turn to open.

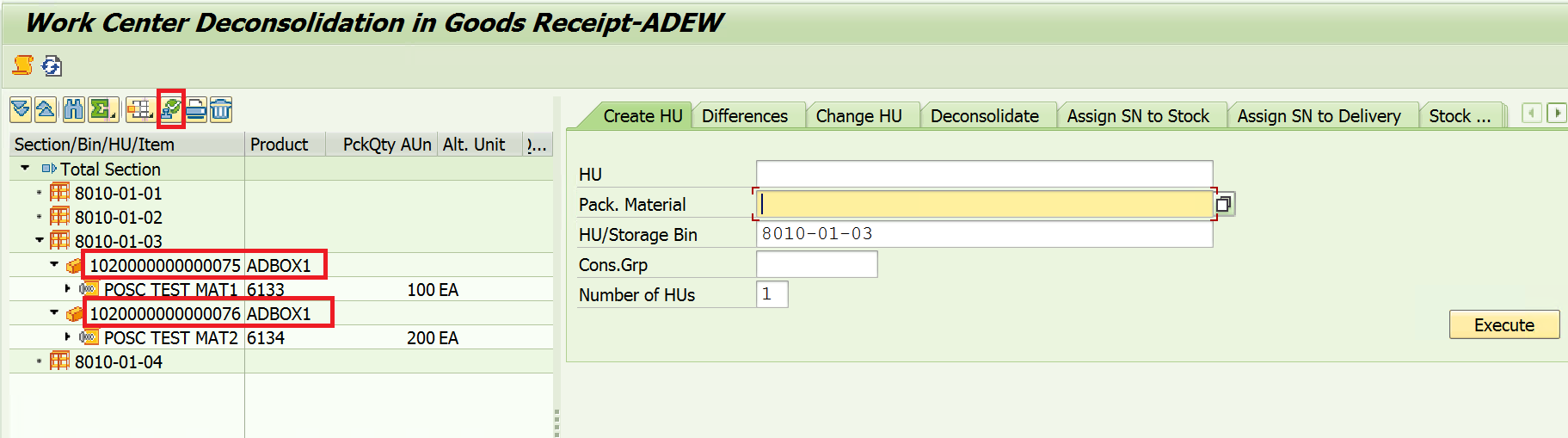

Now do the deconsolidation in work center.

Create two new Hus to pack individual products.

Once packed in two individual Hus click on complete HU process button.

(once deconsolidation process completed then it will turn to open.)

In Mon we can observe that two HU’s are going to different Bins.

Conclusion: By above configurations and testing, I hope you understand how we execute Deconsolidation in POSC process.

Comment for wider reach, thanks for your time to read the blog.

Introduction:

Now a days most of the all-value-added services are being performed on the product in the warehouse before put away the products.

So, to execute the complex activities in the warehouse, we will follow Storage control processes.

Process oriented storage control is one of them.

Will see one POSC examples in inbound side with Unloading, deconsolidation and put away.

Configuration Steps:

- Define Process Oriented Storage Control

1.1. Define external steps

1.2. Define storage process

1.3. Assign storage step process to storage process

1.4. Setup POSC

- Define Warehouse Process type

- Define process type determination indicator

- Determine Warehouse Process type

- Putaway Strategies

5.1. Define storage type search sequence

5.2. Assign storage type to storage type search sequence

5.3. Define put away control indicator

5,4. Specify storage type search sequence for putaway

- Specify work center layout

- Define work center

- Assign bin to Work Center--/N/SCWM/TWORKST

- Deconsolidation

- Define attributes of deconsolidation

- Specify deconsolidation station

- Assign number range intervals to consolidation groups

- Assign Storage Bins to Activity Areas

Testing:

- Create Material Master

- Create Product Master--/N/SCWM/MAT1

- Create a PO---ME21N

- Create Inbound Delivery against to PO---VL31N

- Process the Inbound Delivery---N/SCWM/PRDI

- Create Unloading task

- Confirm the WT---/N/SCWM/MON

- Deconsolidation Process---/N/SCWM/DCONS

- Confirm final putaway

- Define Process Oriented Storage Control

PATH: SPRO->REF IMG-> SCM EWM-> CROSS-PROCESS SETTINGS-> WAREHOUSE TASK-> DEFINE PROCESS ORIENTED STORAGE CONTROL

1.1. Define external steps

1.2. Define storage process

1.3. Assign storage process step to storage process

1.4. Setup POSC

We don’t enter AD03 step because, my put away will taken care by put away strategies.

- Define warehouse process type

PATH: SPRO-> REF IMG-> SCM EWM-> CROSS-PROCESS SETTINGS-> WAREHOUSE TASK-> DEFINE WAREHOUSE PROCESS TYPE

- Define process type determination indicator

4. Determine warehouse process type

- Put away strategies

5.1. Define storage type search sequence

PATH: SPRO-> REF IMG-> SCM EWM->GOODS RECEIPT PROCESS-> STRATEGIES-> STORAGE TYPE SEARCH-> DEFINE STORAGE TYPE SEARCH SEQUENCE

We will create two STSS for two products so that it can go into two different storage types.

5.2. Assign storage type to storage type search sequence.

5.3. Define put away control indicator

5.4. Specify storage type search sequence for putaway

- Specify work center layout

PATH: SPRO-> REF IMG-> SCM EWM-> EWM -> MASTER DATA-> WORK CENTER-> SPECIFY WORK CENTER LAYOUT

- Define work center

- Assign bin to Work Center--/N/SCWM/TWORKST

- Deconsolidation

- 9.1.Define attributes of deconsolidation

PATH: SPRO-> REF IMG-> SCM EWM-> EWM-> GOODS RECEIPT PROCESS>DECONSOLIDATION->DEFINE ATTRIBUTES OF DECONSOLIDATION

Enter the maximum number of WT for putaway HU and also in Deconsolidation HU.

9.2. Specify deconsolidation station

9.3. Assign number range intervals to consolidation groups

- Assign Storage Bins to Activity Areas

TESTING

Material Master--MM01-6133,6134

- Create two materials

Material-6133

Material-6134

- Extend this material master as Product Master---/N/SCWM/MAT1

Product-6133

Product-6134

- Create PO----ME21N

- Create Inbound delivery Against to PO---VL31N

In one HU we are going to pack two materials. (Assume these two products came in one HU)

Select the packaging material and two materials and click on Pack icon, it is distributed to EWM in 1 Pallet with two materials.

- Process the Inbound delivery----/N/SCWM/PRDI

In above screen in EWM we have one HU with two products in it.

In above screen in EWM we have one HU with two products in it.

5.1. Create the unloading warehouse task

From the below picture we can observe that System determines storage process which is assigned to WPT

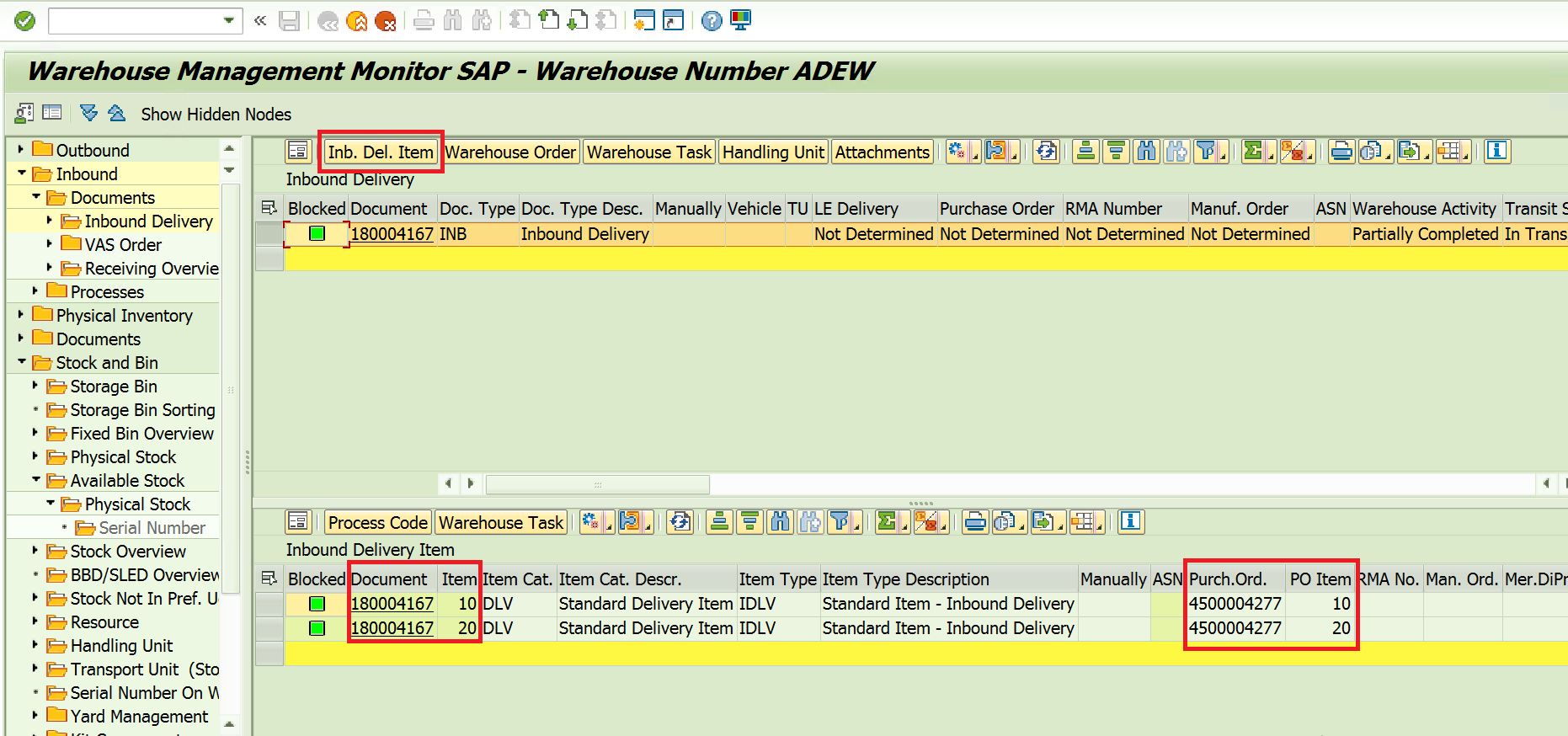

Go to Monitor and check the warehouse order in Inbound delivery

PATH: Inbound delivery->Enter the Inbound delivery no-> Execute-> Select the line item and click on Inbound delivery item Button

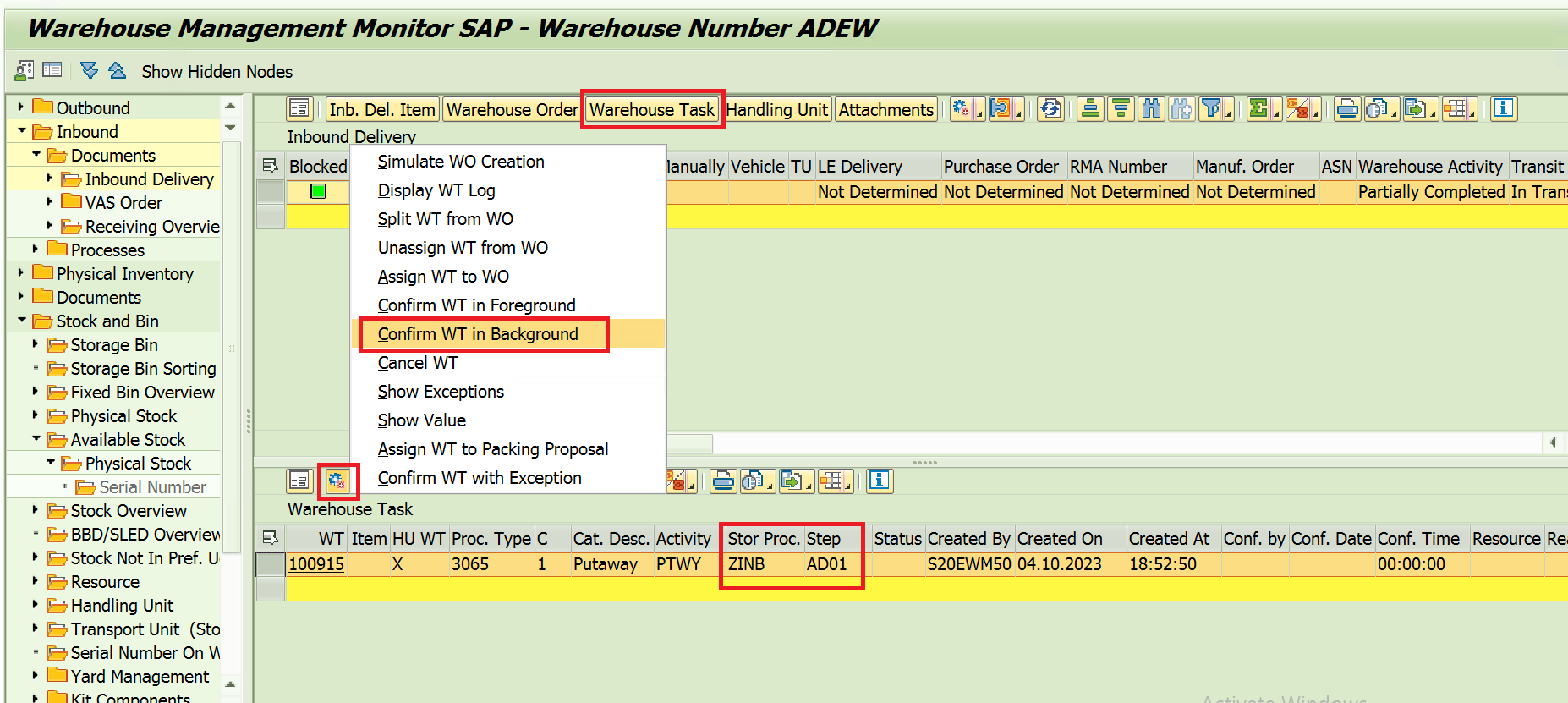

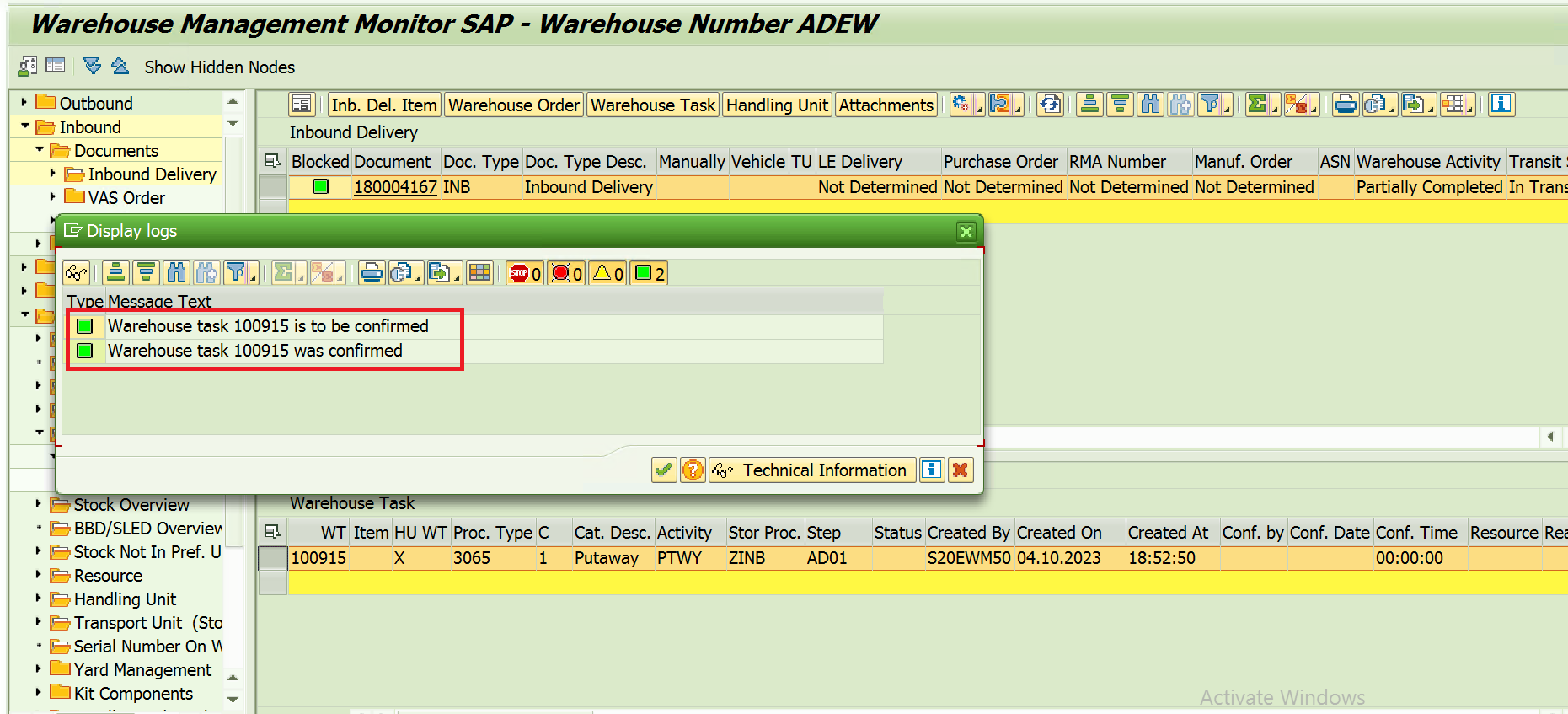

- Check the Storage Process assigned to the warehouse process type, select the line item click on confirm WT in Background.

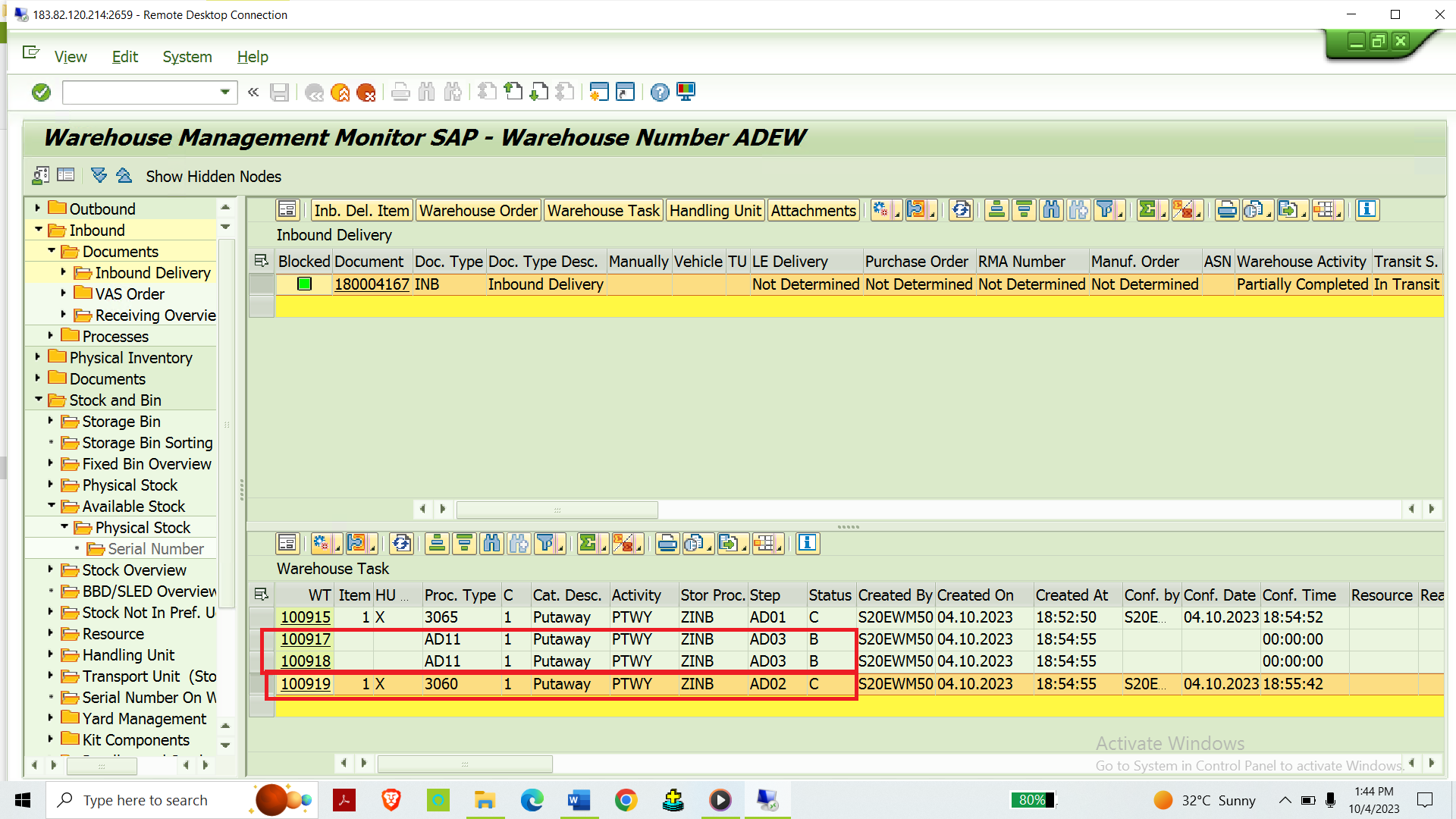

Once we confirm the unloading task system will create 3 more tasks, two are in waiting status -B, one more task for move the HU to Deconsolidation work center.

once deconsolidation process completed then it will turn to open.

Now do the deconsolidation in work center.

- Deconsolidation Process -----/N/SCWM/DCONS

Create two new Hus to pack individual products.

Once packed in two individual Hus click on complete HU process button.

- confirm the final put away task after deconsolidation.

(once deconsolidation process completed then it will turn to open.)

In Mon we can observe that two HU’s are going to different Bins.

Conclusion: By above configurations and testing, I hope you understand how we execute Deconsolidation in POSC process.

Comment for wider reach, thanks for your time to read the blog.

3 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- Query in SAP EWM Deconsolidation Processing (Exception - Cancel Put Away WT after HU Step Complete) in Supply Chain Management Q&A

- LOSC not working for Combined Put away for HU with Multiple Items in Supply Chain Management Q&A

- SAP® Extended Warehouse Management in SAP S/4HANA 2023 – What’s New in Supply Chain Management Blogs by SAP

- Alles über Dekonsolidierung, Anwendungsfälle und Business Anwendung in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |