- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP APO Demand Planning for Carve Out

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ankuagra

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-26-2023

10:17 AM

Dear SAP Friends,

Happy Reading !!!!!!!!

Welcome to one of the Interesting Topic in SAP APO Demand Planning

With the “new normal” we all came across recently, divestment is the focus area of the business houses. Executing SAP carve-out projects on ECC or S/4HANA smoothly and effectively is critical in the success of a merger or acquisition. These SAP projects has to undergo long laundry list for SAP and non-SAP applications demerger. Here in this blog post we will be discussing about how SAP APO Demand Planning can be carved out.

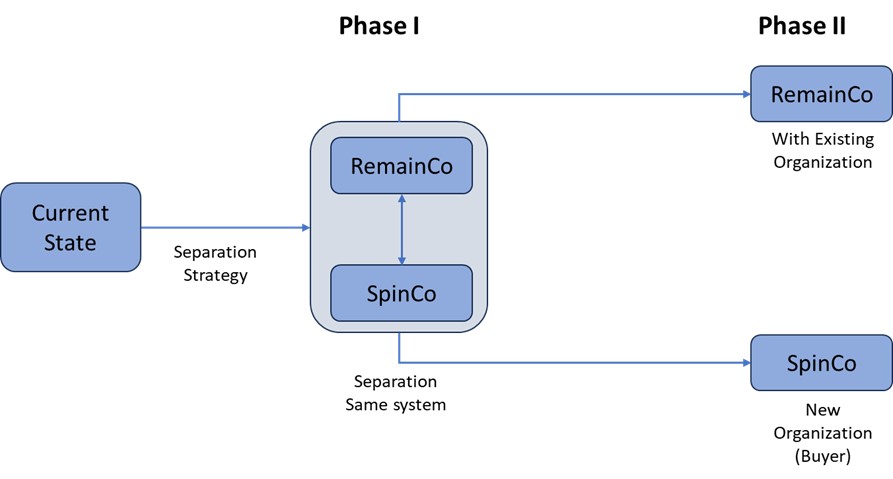

There are multiple carve-out strategies, following figure represents one of the strategy where initially systems got separated in same system and later in second phase it separated for respected organizations, please refer to SAP Blog posts for carve-out.

Key Areas in SAP APO – Demand Planning to focus on for separation:

Phase I

Phase II

Includes all the steps from Phase I, additionally to perform:

Data load options from source system to SAP APO - BWl

Realignment

Create new CVC for the new locations, as all the products needs to be mapped to new location as follows:

Use realignment function to generate new CVC based on existing CVC of a Master Planning Object Structure (MPOS), and to copy data from the existing CVC (source) to the new CVC (target). One can also specify to deletes the original CVC and its data.

Performs the following activities:

Tcode: /SAPAPO/RLGCOPY

Realigning InfoCubes

If you have a requirement to realign the data at infocube level, that is also possible, which have a similar structure to the Master Planning Object Structure(MPOS). The InfoCube must contain all the characteristics that are in the realignment table for the MPOS.

The main advantage of realignment over copy is that realignment creates the target CVC’s if they are not available in the POS.

Update Selection Profiles

Use the transaction /SAPAPO/MC77 to update the selection profile, in our scenarios we have to update the new plants or create the selection profiles with new plants.

User restrictions

As now there will be 2 different organizations in single system, there might be a requirement that one planner responsible for planning for one location should not see or plan the data for other locations, there are multiple ways to implement the user restrictions:

Proportional factor

As the proportional factors are dependent on CVC hence it is required to delete the old CVC (CVC of the products which are new plants now)

The resulting proportional factors for a CVC are time-dependent. The system calculates them for each time bucket within the horizon. This is how the system calculates the proportional factors.

For more information on other steps, please visit the community page. Here you will be able to leverage learnings from carve-out challenges and details about SAP APO, SAP news, SAP customer stories and other resources to stay ahead and ensure business continuity.

If you have remaining questions and need further guidance, navigate to SAP’s Ask a Question site to receive answers from SAP Supply Chain experts.

Happy Reading !!!!!!!!

Welcome to one of the Interesting Topic in SAP APO Demand Planning

With the “new normal” we all came across recently, divestment is the focus area of the business houses. Executing SAP carve-out projects on ECC or S/4HANA smoothly and effectively is critical in the success of a merger or acquisition. These SAP projects has to undergo long laundry list for SAP and non-SAP applications demerger. Here in this blog post we will be discussing about how SAP APO Demand Planning can be carved out.

There are multiple carve-out strategies, following figure represents one of the strategy where initially systems got separated in same system and later in second phase it separated for respected organizations, please refer to SAP Blog posts for carve-out.

SAP Carve-out

Key Areas in SAP APO – Demand Planning to focus on for separation:

Phase I

- Deciding the strategy to have separate SAP APO BW structure or use the same for carve-out data (In this blogpost we will be considering same BW structure).

- Creation of Master data in APO (Product, Location, CVC, etc.)

- Load Master data from source system (ECC) to SAP APO BW

- Delete the CVCs for products moved to new plants

- Creation of new selection profiles

- Update the RemainCo selection profiles by removing the products moved to new company.

- Update proportional factors.

- Update the process chain

- Validate any data specific hard coding in custom programs

- Introduce authorization control

Phase II

Includes all the steps from Phase I, additionally to perform:

- Validate the source and target system connections

- System clone

- Delete Master and Transaction Data

- Reload data or SpinCo

Data load options from source system to SAP APO - BWl

Realignment

Create new CVC for the new locations, as all the products needs to be mapped to new location as follows:

realignment

Use realignment function to generate new CVC based on existing CVC of a Master Planning Object Structure (MPOS), and to copy data from the existing CVC (source) to the new CVC (target). One can also specify to deletes the original CVC and its data.

Performs the following activities:

- It copies notes to the target CVC and does not overwrite an existing note.

- It changes generated selections to reflect the realigned CVC.

Tcode: /SAPAPO/RLGCOPY

Realigning InfoCubes

If you have a requirement to realign the data at infocube level, that is also possible, which have a similar structure to the Master Planning Object Structure(MPOS). The InfoCube must contain all the characteristics that are in the realignment table for the MPOS.

The main advantage of realignment over copy is that realignment creates the target CVC’s if they are not available in the POS.

Update Selection Profiles

Use the transaction /SAPAPO/MC77 to update the selection profile, in our scenarios we have to update the new plants or create the selection profiles with new plants.

User restrictions

As now there will be 2 different organizations in single system, there might be a requirement that one planner responsible for planning for one location should not see or plan the data for other locations, there are multiple ways to implement the user restrictions:

- Create authorization roles under ‘APO 3.0 Authorization Object:..’ and specify the locations which planner wanted to view or change in the planning book (/SAPAPO/SDP94)

- Implement the BADI: /SDP_SELECTOR and restrict the planners for the locations

- Above 2 methods are not called for all tcodes, if you want to restrict the planners from all the tcode, you can implement the enhancements, majorly in 2 function modules

- /SAPAPO/LOC_LOCNO_GET_LOCID

- /SAPAPO/LOC_LOCID_GET_LOCATION

Proportional factor

As the proportional factors are dependent on CVC hence it is required to delete the old CVC (CVC of the products which are new plants now)

The resulting proportional factors for a CVC are time-dependent. The system calculates them for each time bucket within the horizon. This is how the system calculates the proportional factors.

- In each time bucket, the system sums the key figure values of all the CVC. The time bucket has been specified by the user.

- In each time bucket, the system divides the key figure value of each CVC by the total obtained in step (1), thus obtaining a proportional factor for each time bucket.

For more information on other steps, please visit the community page. Here you will be able to leverage learnings from carve-out challenges and details about SAP APO, SAP news, SAP customer stories and other resources to stay ahead and ensure business continuity.

If you have remaining questions and need further guidance, navigate to SAP’s Ask a Question site to receive answers from SAP Supply Chain experts.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

- SAP Field Logistics: Centralized Supplier Item Repository for an Optimized Rental Process in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |