- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- EWM – New picking queues for picking materials mor...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Chethan_tv

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-07-2023

7:56 PM

Introduction: I am SAP certified EWM functional consultant, currently working in A&D (Aerospace & Defense) sector. Writing blog on one of the scenarios I have faced & successfully implemented.

Scenario: During the picking process, clerk/user need new picking queues in all activity area/zones for materials with weight > X kg/lbs. So that user can separately pick heavy orders and physically drop them off at the station specifically designed for heavy materials.

For this scenario, we need to configure new WOCR & additional item filter using BADI (optional explained in end). A new picking queue with a custom table & BADI for queue determination.

Configurations:

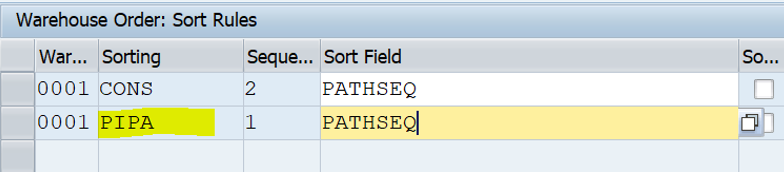

1) Define Sort rules for Warehouse Task

SPRO > EWM > Cross process settings > Warehouse Order > Define Sort rules for Warehouse Task

Provided WO number range is defined at warehouse level, use this path to define sort rule PIPA

Define Sort fields

2) Define filters for warehouse order creation Rules

SPRO > EWM > Cross process settings > Warehouse Order > Define filters for warehouse order creation Rules

Set HEVY filter with filter type: warehouse task

with min weight X (50) pounds

3) Define limit Values for the size of the WO

SPRO > EWM > Cross process settings > Warehouse Order > Define limit Values for the size of the WO

For limiting total weight per WO, can use max weight or max number of items per WO.

limiting number of tasks will not give guarantee of total WO weight, so we can set max weight as 500 LB.

Set HEVY limit, value type warehouse task.

4) Define packing profile for WO creation rule

SPRO > EWM > Cross process settings > Warehouse Order > Define packing profile for WO creation rule.

Set pack profile that will be used as pick HU for picking heavy items.

5) Define Creation Rule for WO

SPRO > EWM > Cross process settings > Warehouse Order > Define Creation Rule for WO

New WO is defined with all rules

Storage process also can be given to direct these materials directly to GI-ZONE or to specified location.

6) Define Search Sequence for WOCR

SPRO > EWM > Cross process settings > Warehouse Order > Define Search Sequence for WOCR

New WOCR is assigned to all activity areas with sequence 1

So that system at first filters heavy items before filtering other materials.

Search sequence is defined for PICK activity (missing in screen shot)

7) Define Queue

SPRO > EWM > Cross process settings > Resource management > Define queues.

Define new queues for all zones (activity areas)

8) Queue determination

This is the point where system fails to assign picking queue.

Reason: For an activity area, currently there is already a queue assigned, now we cannot assign another queue for same AA.

As Queue determination is done in WT creation, system will not check/assign new queues after WO determination.

For this purpose, we can use BADI: /SCWM/IF_EX_RSRC_QU_DET - Queue Determination at WO Creation. Which calls custom table (sample shown below) that updates WO with a new queue for that AA.

Above configuration will suffice the requirement.

As item filter is at item level & if client wants to consider individual each weight of material, then we can use BADI: /SCWM/EX_WHO_FLT_IL – additional filter at item level. With this we can have as many filters as we can.

Hope this was useful.

I appreciate your feedback, that will help me to improve writing blogs further.

Thanks

Scenario: During the picking process, clerk/user need new picking queues in all activity area/zones for materials with weight > X kg/lbs. So that user can separately pick heavy orders and physically drop them off at the station specifically designed for heavy materials.

For this scenario, we need to configure new WOCR & additional item filter using BADI (optional explained in end). A new picking queue with a custom table & BADI for queue determination.

Configurations:

- Define Sort rules for Warehouse Task.

- Define filters for warehouse order creation Rules

- Define limit Values for the size of the WO.

- Define packing profile for WO creation rule.

- Define Creation Rule for WO.

- Define Search Sequence for WOCR

- Define Queue

- Create custom table for Queue determination

1) Define Sort rules for Warehouse Task

SPRO > EWM > Cross process settings > Warehouse Order > Define Sort rules for Warehouse Task

Provided WO number range is defined at warehouse level, use this path to define sort rule PIPA

Define Sort fields

2) Define filters for warehouse order creation Rules

SPRO > EWM > Cross process settings > Warehouse Order > Define filters for warehouse order creation Rules

Set HEVY filter with filter type: warehouse task

with min weight X (50) pounds

3) Define limit Values for the size of the WO

SPRO > EWM > Cross process settings > Warehouse Order > Define limit Values for the size of the WO

For limiting total weight per WO, can use max weight or max number of items per WO.

limiting number of tasks will not give guarantee of total WO weight, so we can set max weight as 500 LB.

Set HEVY limit, value type warehouse task.

4) Define packing profile for WO creation rule

SPRO > EWM > Cross process settings > Warehouse Order > Define packing profile for WO creation rule.

Set pack profile that will be used as pick HU for picking heavy items.

5) Define Creation Rule for WO

SPRO > EWM > Cross process settings > Warehouse Order > Define Creation Rule for WO

New WO is defined with all rules

Storage process also can be given to direct these materials directly to GI-ZONE or to specified location.

6) Define Search Sequence for WOCR

SPRO > EWM > Cross process settings > Warehouse Order > Define Search Sequence for WOCR

New WOCR is assigned to all activity areas with sequence 1

So that system at first filters heavy items before filtering other materials.

Search sequence is defined for PICK activity (missing in screen shot)

7) Define Queue

SPRO > EWM > Cross process settings > Resource management > Define queues.

Define new queues for all zones (activity areas)

8) Queue determination

This is the point where system fails to assign picking queue.

Reason: For an activity area, currently there is already a queue assigned, now we cannot assign another queue for same AA.

As Queue determination is done in WT creation, system will not check/assign new queues after WO determination.

For this purpose, we can use BADI: /SCWM/IF_EX_RSRC_QU_DET - Queue Determination at WO Creation. Which calls custom table (sample shown below) that updates WO with a new queue for that AA.

Above configuration will suffice the requirement.

As item filter is at item level & if client wants to consider individual each weight of material, then we can use BADI: /SCWM/EX_WHO_FLT_IL – additional filter at item level. With this we can have as many filters as we can.

Hope this was useful.

I appreciate your feedback, that will help me to improve writing blogs further.

Thanks

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- Advanced Shipping and Receiving Simplifying the Connectivity in Supply Chain Management Blogs by Members

- IBD changing Date of Manufacture (DOM) and Shelf life expiration date (SLED) on material Batch in Supply Chain Management Q&A

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

- SAP B1 Production Order - Stock Pick List including Batch Codes and BBE Dates in Supply Chain Management Q&A

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |