- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Elasticity of batch management in subcontracting u...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

12-03-2018

12:23 PM

Purpose:

To enhance the stock visibility using Batch traceability and fix the problems related to subcontracting process using delivery if components used are batch manged item. Customers are using subcontracting using delivery and the receipt of finished products is posted in ''Decentralized(EWM) or HU manged location. The components to be provided to vendor are batch managed.

This blogs specifically deal with EWM managed location and IM managed location issues. For HU. managed location, subcontracting using delivery will be published in latter series.

Overview:

There are constraints to carry out receipt of FG material in EWM managed location because the consumption of subcontracting components(543) is driven in background through delivery and it is not dailog mode driven. It is not possible to edit quantities, or enter any batch number because it is posted in background. The components provided are unknown in the delivery and are posted automatically in background.

Since components to be provided to Vendor is batch manged and batch is not specified either in PO nor in delivery, system tries to determine batches with batch determination functionality using function VB_BATCH_DETERMINATION. If system doesn't return any value, receipt process cannot be conducted and it brings error.

Solution:

As of SAP enhancement package 4 for SAP ERP 6.0 (SAP_APPL 604), there is a business function Outsoured Manufacturing (LOG_MM_OM_1). This business function facilitates all aspects of Subcontracting Process. This function enables to enter subcontracting components in Inbound delivery. As a result of this, information of used batches and component quantities can be assigned.

After activation of this business function, switches will be created and a New t code ME2ON subcontracting cookpit is created and it can be used to create delivery.

- Create a subcontracting PO.

If required, you can enter a batch here and same will be copied in ME2ON. But if multiple batches needs to be sent to vendor, this will not work. So, keep it blank

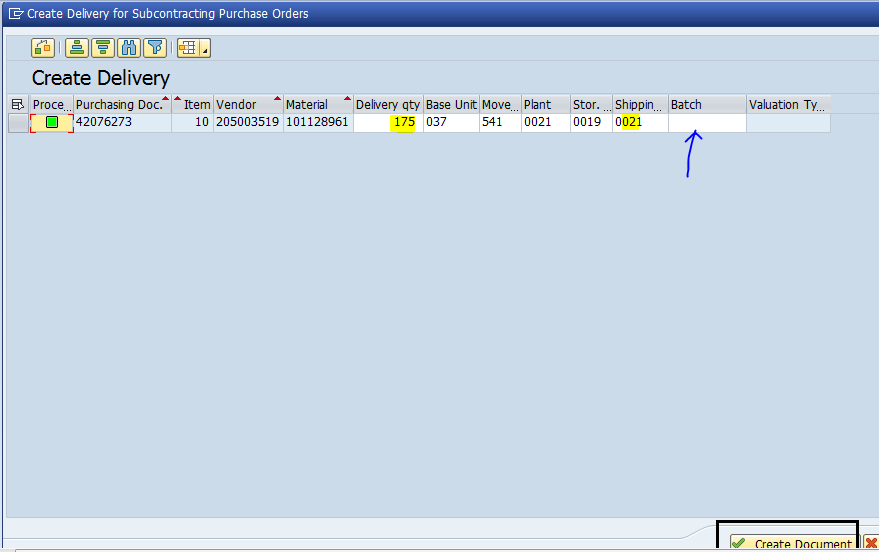

2) Create delivery using ME2ON

Select the line corresponding to PO and click on create delivery.

3) A dialog box information is generated where Quantity can be changed, storage location,shipping point and even batch can be assigned.

Constraints:

However, SAP has given no button to send multiple batches of the component to vendor nor there is any function to call batch determination.

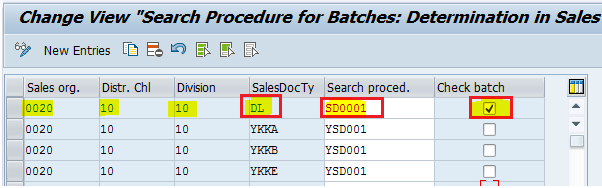

If we recall the determination functionality, we can call batch determination on deliveries which have Sales order reference. But in this case, subcontracting deliveries are created without any reference to sales order and calling Batch determination in subtracting delivery is bit tricky.

However, this can be achieved as below

Check the configuration of delivery document type of subcontracting in customizing(OVLK)

And assign this default order type to Batch search procedure in OCHA with Sales org, distribution channel and division.

Activate automatic batch determination on subcontracting item category

Maintain condition record in VCH1 for SD batch determination.

4) Lets create delivery now, change the quantity to 105, say we need to transfer partial Quantity to vendor and click on create document button.

Note:Batch determination is called in background as below.

5) A delivery is created

How ME2ON or ME2O creates SD delivery, it cannot be explained in this single blog, it will take time to write another blog to mention mechanism of creating SD delivery via subcontracting.

6) Check the delivery.

Multiple batches have been assigned and Batch split is called.

On batch split screen, it can be observed how batch determination is conducted.

Batch determination is called on FIFO principle with characteristics LOBM_LWEDT

A) To call batch split in subcontracting delivery, below customization is mandatory.

Usage ''CHSP'' Batch split with Subcontracting delivery type and item types.

B) Pick the delivery in EWM, create and confirm Warehouse Task and post PGI from EWM. ERP delivery document is updated.

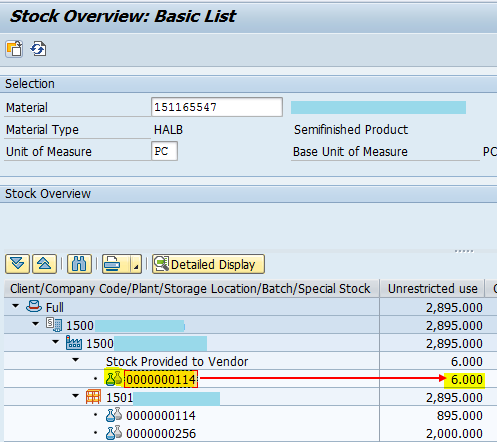

7) Check stock of 4 batches in MMBE

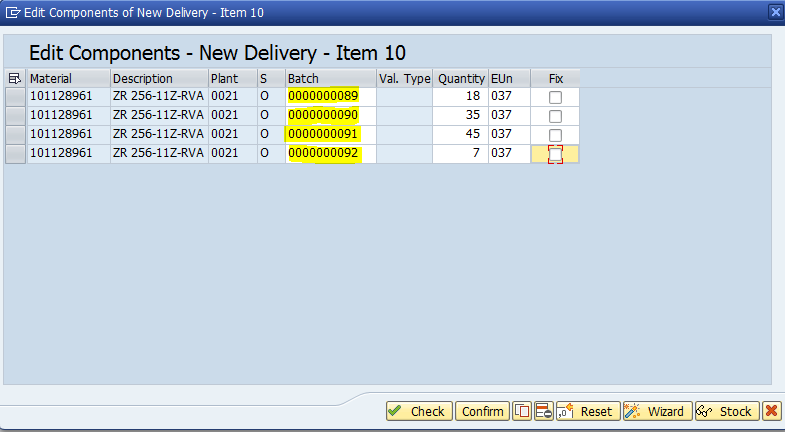

4 batches 89,90,91 and 92 have been transferred to vendor.

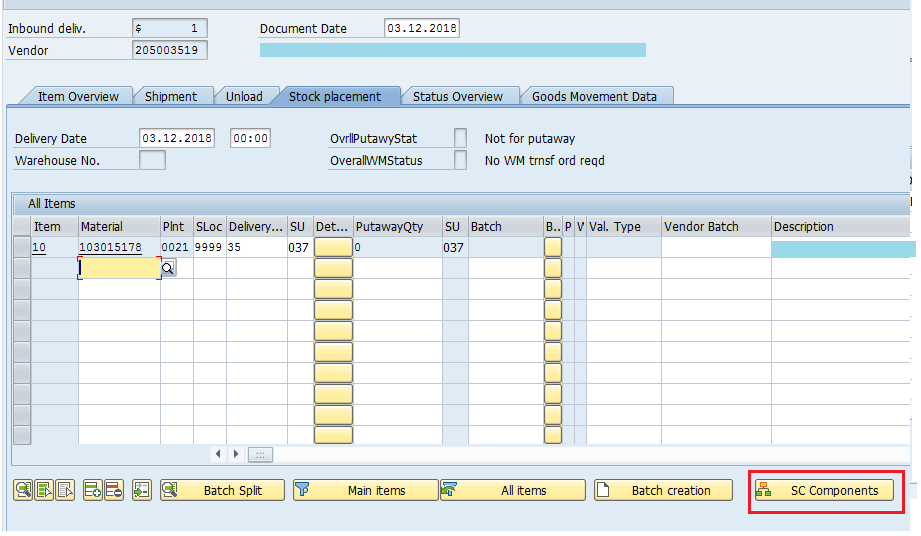

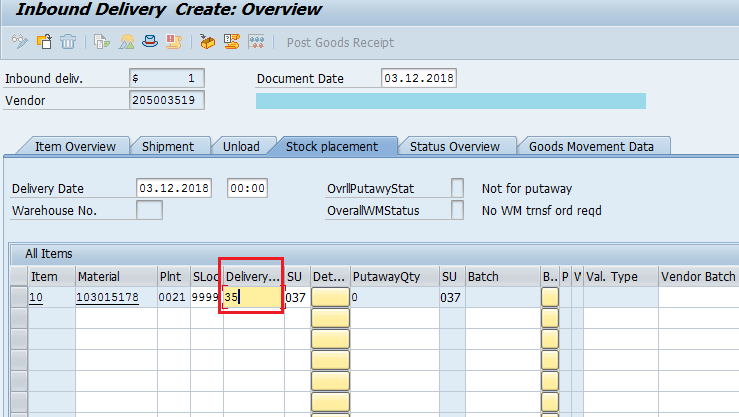

8) Create Inbound delivery to post GR and consumption of materials.

With the activation of business function, Subcontracting components(SC) Button is activated.

9) BOM Explosion in Inbound delivery.

BOM is exploded in inbound delivery where business can check what quantity and batch had been sent to vendor, this functionality gives a leverage to edit the quantity, batch or even shipping point.

The required batches which have been sent to vendor can be displayed.

10) Click on Copy button to generates extra lines to incorporate 4 different batches which was transferred to vendor(541)

11) Change the GR quantity in inbound delivery because we had sent partial component quantities t vendor(541)

12) Check all the quantities before posting, SC component button

13) Post the GR finally.

GR is posted and batches are being checked during 543.

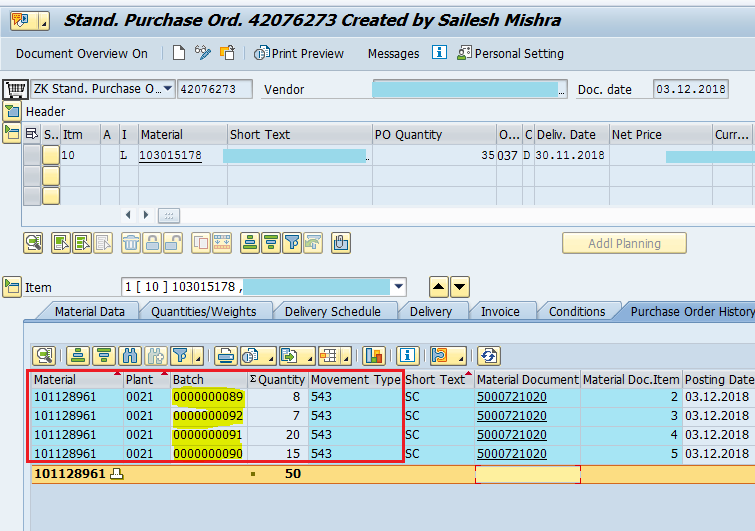

14) Check the Purchase order History tab in ME23N

The GR is posted and delivery is updated in PO.

You can track consumption of components in PO also. The required batches which were transferred and consumed are updated.

15) Check the Delivery also where Purchase order is updated.

The link between Purchase order and delivery is established.

How does PO and delivery linked?

It is important to do customization in item category usage in shipping. Item usage ''V'' is generated after activation of Business function( LOG_MM_OM_1).

Note:->Item usage is hard coded

What if Batch number is not entered in delivery and it is replicated to EWM?

- If delivery is created either my ME2O or ME2ON, batch field is not mandatory and it allows to save delivery without batch. The simple logic behind the programming is that if component provided to vendor is not batch managed then it makes no point of making this field mandatory.

2) A delivery is created in ERP and it is distributed to EWM without batch and we get an error in EWM.

So, we need to have batch in subcontracting during delivery else WT cannot be created

Customers using IM managed location for FG receipt

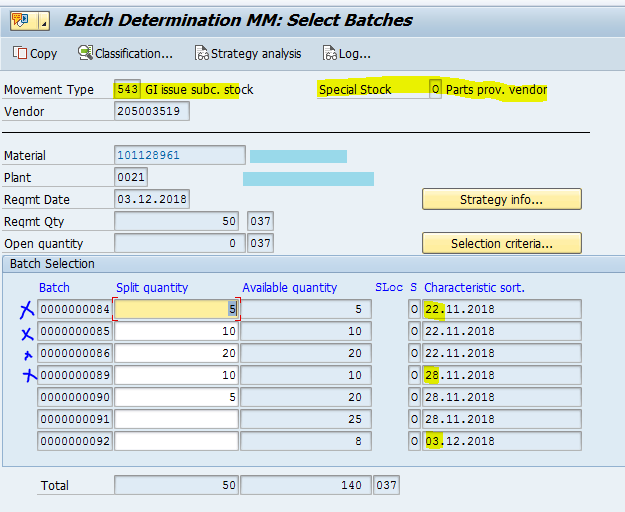

- Create a subcontracting PO and create delivery via ME2ON for shipping components to vendor.

50 pcs is sent to vendor,

here we have batch split of 3 batches to vendor.

2) Post the GR of FG in IM managed location via MIGO

It would be great idea to call batch determination in MIGO screen.

But required batches have not been picked. System has picked batches as per Last GR date, characteristics ''LOBM_LWEDT''. There is link in SAP to connect 541 to 543, but using standard Badi which can do this.

Note:A configuration is required to call MM batch determination on movement type in conjugation with maintaining a condition record in MBC1.

3) A sorting rule has been assigned in MBC1(543 O) movement type to call batch determination.

4) To link 541 batches to 543''O'' batches you need to check the characteristics of 541 movement type batches and correspondingly you can do a manual sorting like below.

since, the batches had last GR date, so we can conduct manual sorting on this,

5) The correct batches have been sorted now, as below

6) Copy the required batches and they are linked in MIGO now

Post the GR, PO is updated.

And consumption of batches can be tracked.

What if customers doesn't agree to activate business function LOG_MM_OM_1?

In that case, GR posting of FG materials should conducted in IM manged location. Business can use MIGO transaction to specify exact quantity of component consumed and book them at this location. Once booking is done, business can move the product from IM managed location to EWM managed location via 311 movement type, which will create an Inbound delivery and warehouse request in EWM which can be putawayed latter,

A) Use MIGO to book the posting of FG in non ewm manged location.. There is an option to assign 541 batch which is sent to vendor to 543 batch.

Assign the required batch in MIGO

B) After posting material document is generated because storage location is IM managed.

C) Use MIGO to transfer FG from IM(1504) to EWM(1501) managed location.

After posting an inbound delivery is created which is distributed to EWM system

D) Automatic GR Posting have been done in EWM through PPF action and same is communicated to ERP via Queue.

E) Create and Confirm Warehouse Task in EWM, and produced Subcontracting Product is putawayed in destination storage bin.

F) The product is putawayed and all status have been completed successfully

Hence the topic ends here. I would wait for any improvement or correction required to make this blog more useful. In next blog, i would write on Subcontracting with Handling Units.

Best regards

Shailesh MIshra

References.

SAP KBA and consulting notes

645119 - Problems for subcontracting using delivery

2689543 - Stuck queue in ERP issuing "Error when creating document flow for delivery XYZ"

2161961 - Select multilple batches in subcontracting

5 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

BI

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Change History

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

FINANCE

1 -

Freight Settlement

1 -

FSM

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Material Master changes

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PowerBI

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

SAC

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP FSM

1 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- Sending ASN from Freight Order (embedded TM) in Supply Chain Management Q&A

- Understanding Network Partner Integration in SAP Business Network for Logistics in Supply Chain Management Blogs by SAP

- Instance specific Authority Control in SAP S/4HANA Transportation Management in Supply Chain Management Blogs by SAP

- Blog Series – SAP S/4 HANA Supply Chain for TM – 07 – Dimensional weight and TM charge calculation in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 6 | |

| 4 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |