- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Dynamic BIN Determination Based on Specific Requir...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Hello All,

I have seen lot of question's on the Bin Determination and concept of fixed versus dynamic bin determination but didn't find any example with Working Solution explaining the EWM standard functionality . So i have tried to put my understanding in words for the community who want's to understand EWM functionality through working example.

Dynamic Bin Determination is a crucial requirement in Extended Warehouse Management systems. It allows for efficient utilization of storage space and improved inventory management by automatically determining the appropriate bin for goods based on various factors.

Suppose Business have a scenario where Products are stored in Multiple Storage Location and multiple BIN but Picking need to happen based

- Available Quantity

- Goods Receipts Date and Time

Use Case 1: Product need to Picked from Storage Type and Bin which have Less Available Quantity with Good Receipt Data and Time

User Case 2: Product need to Picked from Storage Type and Bin which have More Available Quantity with Good Receipt Data and Time

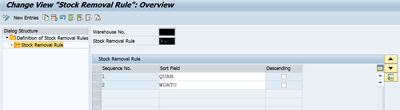

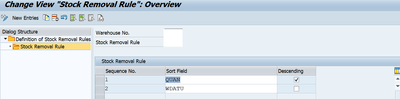

Firstly the Picking rule need to be created based on the requirement i.e.

- Available Quantity in the Storage Bin

- Goods Receipts Date and Time

Fig :1

Fig:2

Now as per the EWM Outbound Process perform below steps as per configuration :

- Step 1: Map Document Types from ERP System to EWM

- Step 2: Map Item Types from ERP System to EWM

- Step 3: Define Storage Type

- Step 4: Define Warehouse Process Type

- Step 5: Determination of Warehouse Process Type

- Step 6: Determination of Storage Type Search Sequence

- Step 7: Assign Storage Bin to Activity Area

- Step 8: Define sort Sequence for Activity Area

- Step 9: Create Sorting Bin via TCode /n/SCWM/SBST

Now as per the Scenario we will create the Transaction Data

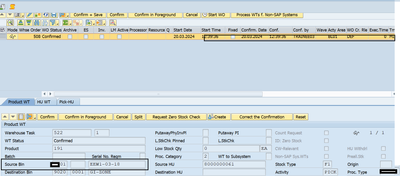

Create Sales Order >> Create Outbound Delivery>>Display Outbound Delivery Request >> Create Warehouse Task>> Confirm Warehouse Task>>Perform Loading>> Perform Goods Issue

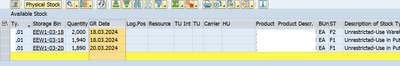

Current Stock Position in EWM :

In the Warehouse Order we can see the Source Bin determined in EEW1-03-20 reason being the Stock Removal rule is Performing check on below parameter:

- System is checking the Bin in which Stock is Less as the Descending Checkbox is unchecked (Check Fig:1)

- System is checking the Goods Receipts Date and Time

In the Warehouse Order we can see the Source Bin determined in EEW1-03-18 reason being the Stock Removal rule is Performing check on below parameter:

- System is checking the Bin in which Stock is More as the Descending Checkbox is checked (Check Fig:2)

- System is checking the Goods Receipts Date and Time

Conclusion :

- For Use Case 1:

Even though the Material is present in 2 Separate Bin but system preferred Bin EEW1-03-20 over EEW1-03-18 reason being

- Our Stock Removal Rule is based on Available Quantity and Goods Receipts Date where Bin EEW1-03-20 have less quantity even though the Goods Receipts date is Higher

- For Use Case 2

Even though the Material is present in 2 Separate Bin but system preferred Bin EEW1-03-18 over EEW1-03-20 reason being

- Our Stock Removal Rule is based on Available Quantity where is it less and Goods Receipts Date ,where Bin EEW1-03-20 have more quantity and the Goods Receipts date is earlier then Bin EEW1-03-20.

Let me know if this helps i will try to bring more working example from experience.

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- SAP S/4HANA

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- Implementing Automated Storage of TM Attachments in the SAP Document Management System in Supply Chain Management Blogs by SAP

- S/4 Flexible PO Workflow -Approval Limit Check in Supply Chain Management Q&A

- Preferred Alternative UoM for Warehouse Operation in EWM in Supply Chain Management Blogs by Members

- Freight Generation in Data Collation Document using Freight Rate Table or Pricing Multireference in Supply Chain Management Blogs by Members

- The Essential Role of Adverse Media Monitoring in Compliance and Risk Management in Supply Chain Management Blogs by Members

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |