- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- Configuring Time Based Auto-Assembly (TBAA) in SAP...

Product Lifecycle Management Blogs by SAP

Dive into product lifecycle management news, learn about digitalizing PLM for the digital supply chain, and stay informed with product updates from SAP.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-01-2023

2:49 PM

Introduction

With Time Based Auto-Assembly (TBAA), batches of components can be loaded into predefined resource bins to be automatically consumed during the manufacturing process while maintaining full batch traceability.

This capability is frequently used on high-speed or automated manufacturing process, where small non-serialized but batch-managed components are consumed, as seen in a Printed Circuit Board manufacturing process, for example.

In this blog post, we will explore the detailed configuration and utilization of Time-Based Auto-Assembly (TBAA) in SAP Digital Manufacturing.

Configuration

First, create a new Production Process and a new Cloud Process in the "Design Production Processes" app. Add a Start Control and create Input Parameters for Plant, Operation, Resource and Sfcs as follows:

Add the "Auto Assemble" service and map all the necessary Input Parameters accordingly:

Save and deploy it.

Then, choose Additional Options ("...") and select "Edit Header":

To make your Production Process visible in the Service Registry library for calling from other apps, such as POD Designer, switch "Publish to Service Registry" to "ON":

Next, define how the "Auto Assemble" Production Process will be triggered during the manufacturing process. This can be accomplished in various ways, such as using a Business Rule or an Action Button in POD Designer.

You can create a Business Rule to trigger the "Auto Assemble" Production Process automatically as soon as an SFC is started, using the "Manage Automatic Triggers" app, as follows:

Here, you can define an Event Type like "SFC Started," which will trigger an Action to call the "Auto Assemble" Production Process with the necessary Input Parameters when specific conditions are met:

These conditions may include filters for Plant, Resource, Work Center, Material, and others.

Alternatively, you can call the "Auto Assemble" Production Process from an Action Button in your POD.

To do this, add the "Auto Assemble" Production Process to an Action button like "Start" in POD Designer and map the required Input Parameters as follows:

Next, Bins must be created for Resources in the "Manage Resources" app:

This can be done manually or automatically:

Where:

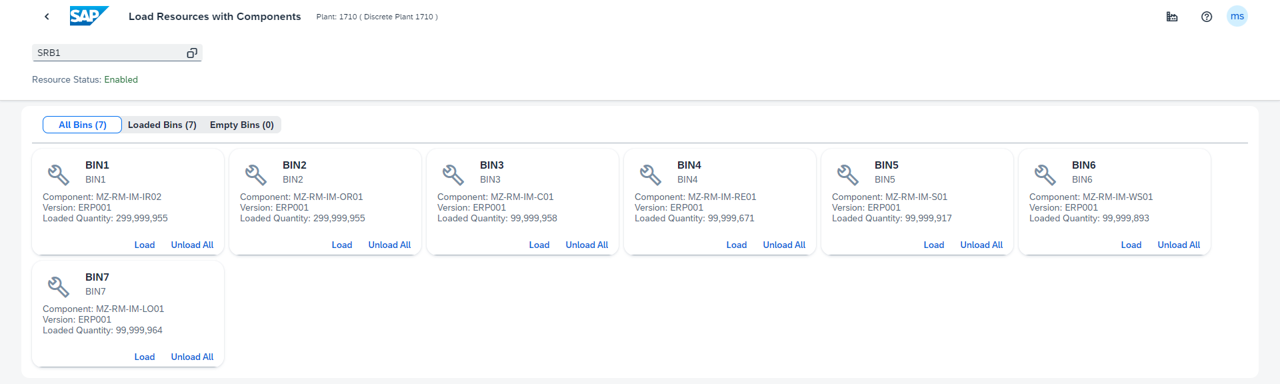

Once created, Bins can be loaded and unloaded in the "Load Resource with Components" app:

Multiple Inventory IDs can be loaded and remain in a queue for a given Resource/Bin combination:

Each Inventory ID can represent a different batch, which will be consumed in the sequence it's queued for each Bin in the "Load Resource with Components" app.

Execution

The Time-Based Auto-Assembly (TBAA) setup is now complete, and you can test it by producing an SFC in an Operation Activity or Work Center POD. This will trigger Time-Based Auto-Assembly after starting the SFC, either via the POD Button or the Business Rule previously configured:

Once the SFC is started, if all goes well and "Auto Assembly" is successfully triggered, check the "Required Quantity" and "Remaining Quantity" columns in the "Assemble (Component List)" plugin to confirm that the components have been automatically assembled and consumed:

You can also verify that the "Auto Assemble" Production Process was triggered in the "Monitor Production Processes" app:

And that the components were properly assembled and consumed in the SFC Report.

Remarks

Conclusion

In conclusion, Time Based Auto-Assembly (TBAA) in SAP Digital Manufacturing presents a powerful solution for enhancing efficiency in high-speed and automatic manufacturing processes, such as Printed Circuit Board manufacturing, while ensuring full batch traceability throughout the production cycle.

It's important to note that TBAA may not be suitable for all production scenarios, particularly those with relaxed flows in their routings. Nevertheless, for those looking to optimize efficiency, reduce errors, and ensure consistent quality in their manufacturing operations, Time-Based Auto-Assembly can be very useful.

In summary, SAP Digital Manufacturing's Time-Based Auto-Assembly offers a reliable and efficient solution to meet the demands of modern manufacturing, delivering precision and traceability in every batch.

Experiencing SAP Digital Manufacturing

You can have a glimpse and experience several aspects of SAP Digital Manufacturing via the Interactive Value Journeys below:

Do you like this post? Please let me know in the comments section what you think. Any feedback is highly appreciated.

Or, if you have any questions, please check SAP Community Q&A Area, or comment down below.

Thanks,

Manoel Costa

With Time Based Auto-Assembly (TBAA), batches of components can be loaded into predefined resource bins to be automatically consumed during the manufacturing process while maintaining full batch traceability.

This capability is frequently used on high-speed or automated manufacturing process, where small non-serialized but batch-managed components are consumed, as seen in a Printed Circuit Board manufacturing process, for example.

In this blog post, we will explore the detailed configuration and utilization of Time-Based Auto-Assembly (TBAA) in SAP Digital Manufacturing.

Configuration

First, create a new Production Process and a new Cloud Process in the "Design Production Processes" app. Add a Start Control and create Input Parameters for Plant, Operation, Resource and Sfcs as follows:

Add the "Auto Assemble" service and map all the necessary Input Parameters accordingly:

Save and deploy it.

Then, choose Additional Options ("...") and select "Edit Header":

To make your Production Process visible in the Service Registry library for calling from other apps, such as POD Designer, switch "Publish to Service Registry" to "ON":

Next, define how the "Auto Assemble" Production Process will be triggered during the manufacturing process. This can be accomplished in various ways, such as using a Business Rule or an Action Button in POD Designer.

You can create a Business Rule to trigger the "Auto Assemble" Production Process automatically as soon as an SFC is started, using the "Manage Automatic Triggers" app, as follows:

Here, you can define an Event Type like "SFC Started," which will trigger an Action to call the "Auto Assemble" Production Process with the necessary Input Parameters when specific conditions are met:

These conditions may include filters for Plant, Resource, Work Center, Material, and others.

Alternatively, you can call the "Auto Assemble" Production Process from an Action Button in your POD.

To do this, add the "Auto Assemble" Production Process to an Action button like "Start" in POD Designer and map the required Input Parameters as follows:

Next, Bins must be created for Resources in the "Manage Resources" app:

This can be done manually or automatically:

Where:

Add from BOM: Allows you to create a resource bin structure based on the BOM.

Add Manually: Allows you to create a resource bin structure manually.

Once created, Bins can be loaded and unloaded in the "Load Resource with Components" app:

Multiple Inventory IDs can be loaded and remain in a queue for a given Resource/Bin combination:

Each Inventory ID can represent a different batch, which will be consumed in the sequence it's queued for each Bin in the "Load Resource with Components" app.

Execution

The Time-Based Auto-Assembly (TBAA) setup is now complete, and you can test it by producing an SFC in an Operation Activity or Work Center POD. This will trigger Time-Based Auto-Assembly after starting the SFC, either via the POD Button or the Business Rule previously configured:

Once the SFC is started, if all goes well and "Auto Assembly" is successfully triggered, check the "Required Quantity" and "Remaining Quantity" columns in the "Assemble (Component List)" plugin to confirm that the components have been automatically assembled and consumed:

You can also verify that the "Auto Assemble" Production Process was triggered in the "Monitor Production Processes" app:

And that the components were properly assembled and consumed in the SFC Report.

Remarks

- Time-based Auto Assembly (TBAA) is not supported for routings with relaxed flows.

Conclusion

In conclusion, Time Based Auto-Assembly (TBAA) in SAP Digital Manufacturing presents a powerful solution for enhancing efficiency in high-speed and automatic manufacturing processes, such as Printed Circuit Board manufacturing, while ensuring full batch traceability throughout the production cycle.

It's important to note that TBAA may not be suitable for all production scenarios, particularly those with relaxed flows in their routings. Nevertheless, for those looking to optimize efficiency, reduce errors, and ensure consistent quality in their manufacturing operations, Time-Based Auto-Assembly can be very useful.

In summary, SAP Digital Manufacturing's Time-Based Auto-Assembly offers a reliable and efficient solution to meet the demands of modern manufacturing, delivering precision and traceability in every batch.

Experiencing SAP Digital Manufacturing

You can have a glimpse and experience several aspects of SAP Digital Manufacturing via the Interactive Value Journeys below:

Do you like this post? Please let me know in the comments section what you think. Any feedback is highly appreciated.

Or, if you have any questions, please check SAP Community Q&A Area, or comment down below.

Thanks,

Manoel Costa

- SAP Managed Tags:

- SAP Digital Manufacturing

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- How to use Digital Manufacturing MDOs within PPD Example: Where-Used Report with Follow-up Actions in Product Lifecycle Management Blogs by SAP

- Error on setup of Discrete Production Orders in Order POD within SAP Digital Manufacturing in Product Lifecycle Management Q&A

- Meet PLM experts from SAP at Hannover Messe 2024 in Product Lifecycle Management Blogs by SAP

- Meet PLM experts from SAP at Hannover Messe 2024 in Product Lifecycle Management Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation in Product Lifecycle Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |