- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Q&A

- Repetitive manufacturing Profile

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Repetitive manufacturing Profile

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 02-26-2024 8:55 AM

Repetitive manufacturing (REM) profile is one of mandatory master data for Repetitive manufacturing process. It controls how-to carry-on planning and confirmation in Repetitive manufacturing process.

However, REM profile could create through system configuration as per business process.

Configuration:

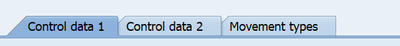

REM Profile has below mentioned sections.

- Control Data1

- Control Data2

- Movement types

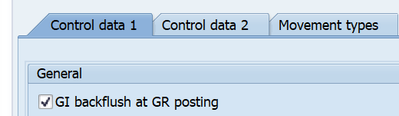

Let’s discuss on Control data1.

GI backflush at GR posting – This check box control whether BOM components consume at the same time when goods receipt happens.

RP confirmations -This would use in case of Make to stock manufacturing and long lead time. Consumption of components could be recorded at a time that is close to time of operations to which it assigned. This help to calculate value of WIP products.

Reporting point could also use to manufacture with /without Kanban.

This is two types Mandatory Reporting point and Optional reporting Point.

Mandatory reporting point: This should use if quantity of production line, need to confirm along with each report point.

Optional reporting -This should use if quantity of production needs to confirm at the end of Production process.

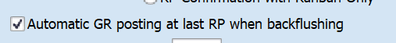

Automatic GR Posting at Last RP when backflushing: This will control to do goods receipt during backflush of Last reporting point.

Process Control: This help separate below process from goods receipt. This could config under node of separate backflushing process.

1.Goods issue

2.Activity posting.

Error correction for Backflushing: This will generate backlog of errors during backflush of components.

Execute correction in dialogue mode: With this, system would ask to fix backflush error immediately during confirmation instead of generating entries in COGI.

With Mandatory option, this would not allow to goods receipt without fixing backflush errors.

With Optional option, it would generate pop-up with all backflush error. But that could skip and post confirmation. Then it would generate entries in COGI.

Let’s discuss on Control data2.

Planned order Reduction: Reduce planned order of material with production version and that of material without production version.

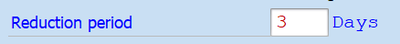

Reduction Period: This is calculated by adding the number of days you enter here to the backflush date. The system reduces all planned orders and run schedule quantities in the period of reduction.

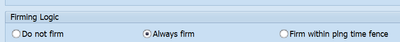

Firming Logic:

With option “Always firm”- Update firming indicator in planned order which generate through Planning table.

With option “Do not firm”- Do not update firming indicator in planned order which generate through Planning table.

With option “Firm within plng time fence”-Update firming indicator in planned order if it falls with planning time fence of material.

Create planned orders when reversing: Will re-create planned order which were reduced during backflush, when reversing backflush.

Aggregate requirements: This will decide whether all dependent requirement of component grouped together to total requirement for a day when there is various requirement for that component on that day.

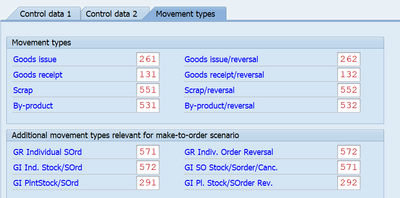

Movement type section has all movement types such as 261,262,131,132 etc.

- SAP Managed Tags:

- SAP ERP,

- SAP Manufacturing Execution

Accepted Solutions (0)

Answers (0)

- Futuristic Aerospace or Defense BTP Data Mesh Layer using Collibra, Next Labs ABAC/DAM, IAG and GRC in Enterprise Resource Planning Blogs by Members

- Asset Management in SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release in Enterprise Resource Planning Blogs by SAP

- Production scheduling profile - Date of manufacturing not filled in on batch in Enterprise Resource Planning Q&A

- Lesson learnt on Process Industry with Production Information System (S4 HANA Custom Development) in Enterprise Resource Planning Blogs by Members

- Lesson learnt on Process Industry with Production Information System (S4 HANA Custom Development) in Enterprise Resource Planning Blogs by Members

| User | Count |

|---|---|

| 108 | |

| 12 | |

| 11 | |

| 6 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.