- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Supply Creation-Based Confirmation (SBC) in SAP S/...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Just to give you insight about the SBC scenario consider a Bike Manufacturing company in plant/001

Figure1: SBC + PAL scenario to support the Business Requirement.

Mr. RAM is working in bike manufacturing company as a SCM consultant. which manufacture the BIKES based on customer specific requirements ( Engine characteristics / Bike Model….)

During the sales order creation process, he wants to provide the customer specific characteristics about finished product and also based upon the stock and planning situation, he has to provide the accurate & reliable order-promising dates ( generating the procurement proposals when the available quantity of requested sales order is insufficient ) . During this process Mr. Ram has to consider the sales & transportation capacities to protect the company business priorities & profitability goals. To support this business requirement he decided to work with aATP( PAL + SBC ) scenario. let’s see the following steps, how aATP will solve the Ram’s business requirement.

Below master data setup is maintained for the Finished product CUSTOM_BIKE for more details about how to activate the ATP check for (Supply Creation) kindly go through my previous blog SBC Activation

Figure2: Master Data details for CUSTOM_BIKE Finished product

Before going through the scenario let’s quickly have look into how PAL will support this requirement .

Product Allocations provides the mechanism to restrict the confirmation of orders with certain order characteristics like e.g. dedicated customers or regions & variant configuration characteristics . This could prevent supply shortage situations caused by a single high volume order to consume significant stocks and thus leaving the other customers orders either down the line or unconfirmed

Figure 3: Product Allocation Sequence

In below Figure 4 we can see that based on different PAL characteristics, the PAL sequence would restrict the Supply Creation process while considering the Sales & Capacity Allocation quota.

Before the Supply Creation process the Sales Allocation quota provides what we want to deliver in specified Bucket(Month/Week/Day ) based on PAL object configuration.

After Supply Creation process the Capacity Allocation quota finally decides how much quantity going to be delivered for the requested delivery date and generating the delivery proposals.

Figure:4 PAL characteristics & sequence with Incoming sales order

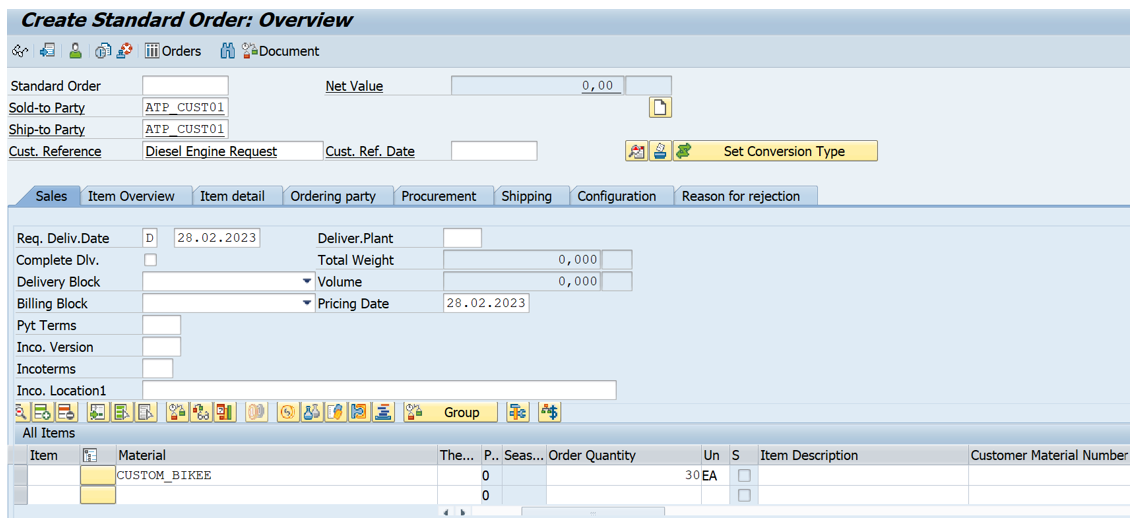

Let’s say on 28.02.2023 Mr. Ram got below requirement based on the following details, that he wants to provide the order promising dates while considering the companies business priorities and profitability goals.

Requested Customer: “ATP_CUST01”

Requested product: “CUSTOM_BIKEE” in plant 0001 with quantity 30 and with following custom configurations Engine Type: “Diesel engine Engine ratio: 1.6 engine rod ratio

Requested date: 28.02.2023.

Now lets see how the aATP(SBC+PAL) scenario process the above details based on below product allocation configuration.

Product Allocation Sequence --- which is having Sales Sequence group ( consumption- Backward-2 months & forward-5 months ) & Capacity Sequence group ( consumption- Backward-0 months & forward-5 months )

we can see the sales & capacity allocation object with Quota maintained in the month bucket based on Sales and transportation capacities

Figure 5:Product Allocation Sequence master data details

Figure 6: sales order details with customer and quantity details

Below we can see during the sales order creation process the system allowing user to enter the customer specific characteristics

Figure 7: classic variant configuration screen for the requested sales order item during sales order creation process.

based on the given details the “Review Availability Check Results” RACR screen providing the confirmation quantities & proposal dates as we can see in below Figure 8.

If we want to know the more details about how the above delivery proposals got generated we can navigate inside RACR screen requirement details .

Figure 8 : RACR Screen with different delivery proposals

Below Figure 9 we can see the detailed flow of ATP check from requested delivery date & quantity to the output confirmation dates and quantities

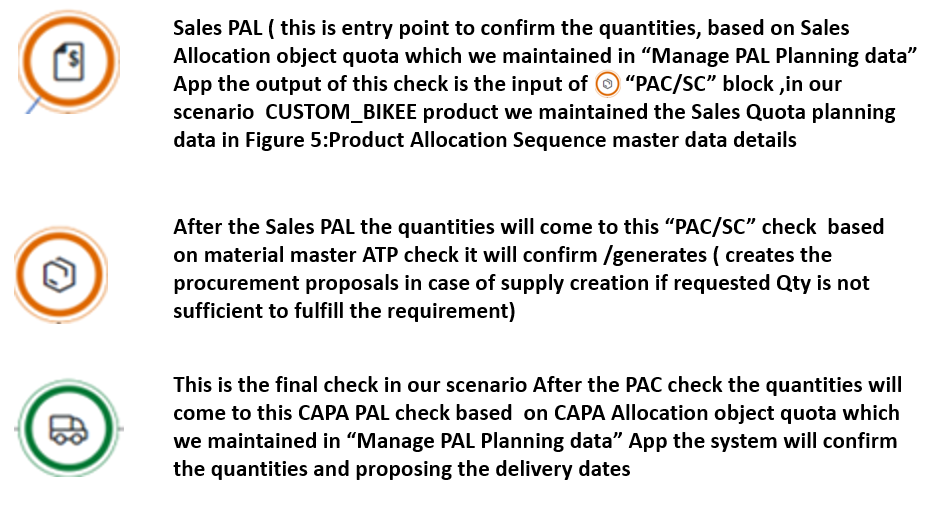

Based on the requested delivery date 24.02.2023 & quantity 30 EA there are multiple checks (Sales PAL --> PAC/SC --> CapaPAL) that are processing the requested quantity for the sales order item for more details kindly refer Figure 3 & Figure 9 .

Figure 9: RACR Screen ATP Check intermediate results

below icons represents the different checks which is happening during the ATP order confirmation process

Figure 10: Different icons during the order confirmation process

In Figure 9, PAL sequence constraints is allocating/restricting the quantities based on the given consumption periods & Consumption direction we can see the above table how the quantities get consumed from different periods based on pivot value in the Consumption Type & Order of Check number values ( on 01.02.2023 for “BIKE_PAL_SEQ” sales allocation object consumption type = Pivot & order of check = 1 based on this it will start the quantities allocation either from Backward / Forward as given in the PAL sequence configuration data ) .

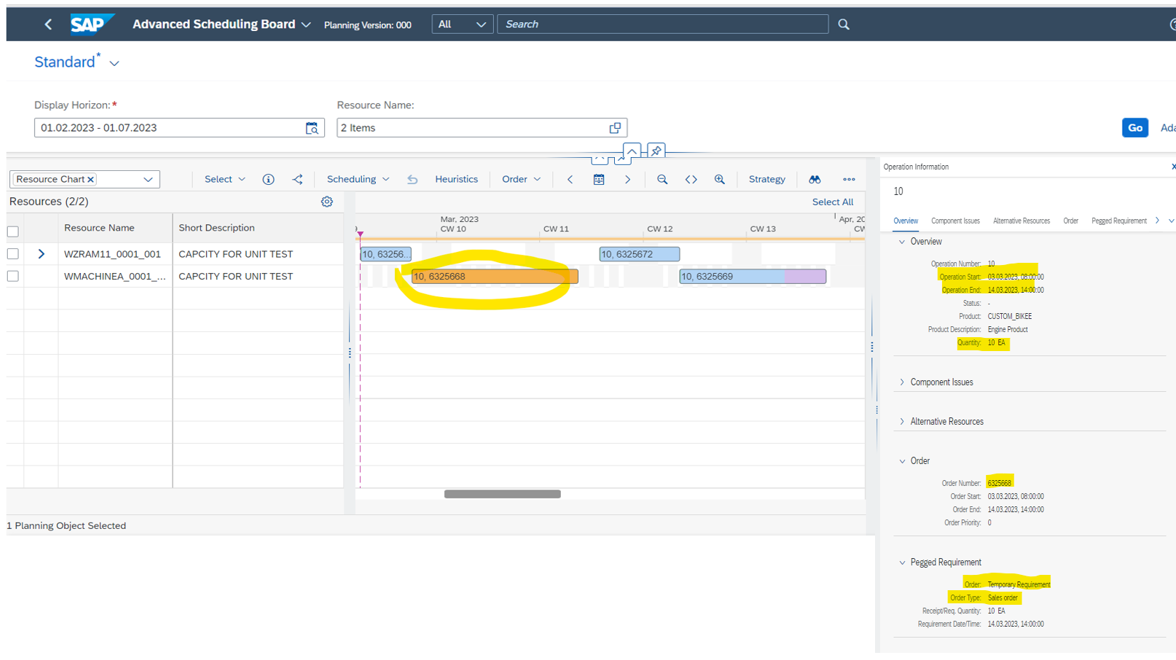

In /SAPAPO/RRP3 transaction product view we can see the temporary requirement along with planned orders & its dependent requirements for “CUSTOM_BIKEE” finished product

Figure 11:RRP3 Product view for CUSTOM_BIKEE finished Product

In above figure we can see one of the Planned order “6325668” created with quantity 10EA, the operation is starting on 03.03.2023-8AM & ending on 14.03.2023-2PM , which is the first delivery proposal from PAC/SC check lets see how its calculated the start & end dates.

In Routing of material CUSTOM_BIKEE we can see below setup , process & Labor details along with workCentre MACHINEA( capacity category ‘001’ we can see the set of activities and formulae’s maintained in capacities tab ).

Figure 12: Routing & WorkCentre master data details

In workcentre we can see each day 8H is available capacity ( 8Am to 4PM ) per day.

In Routing master we maintained setup = 2 H ,Machine = 4 H, Labor = 2 H .

As per given Capacities formulae’s PFB calculations .

----------------------------------------------------------------------------------------------------------------------

Setup = Setup * operation splits = 2 * 1 = 2 H

Process= Machine * Operation quantity / Base quantity = 4 * 10 / 1 = 40 H

Teardown = Labor * Operation quantity / Base quantity = 2 * 10 / 1 = 20 H

-----------------------------------------------------------------------------------------------------------------------

2H + 40H + 20H = 62 H

------------------------------------------------------------------------------------------------------------------------

As per planned order start date 03.03.2023-8am to end date 14.03.2023-2pm total capacity = 62H which is equal to the above calculation

We can use the “ASB”Advanced Scheduling board application to visualize the Resources, Products & Operations in Gantt chart In our case “6325668”/10 operation pegged with temporary sales order (because the sales order we haven’t saved ) we can see the below figure for more details in ASB application .

Figure 13: ASB application Resources & Planned Order Details

Conclusion : with the above steps Mr. Ram is able to achieve his business requirement with help of PAL + SBC Scenario.

- SAP Managed Tags:

- SAP S/4HANA for advanced ATP

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

24 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

159 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,684 -

Product Updates

219 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

- NOTIFICATION FOR FAILED MEASURING POINT VALUES in Enterprise Resource Planning Q&A

- material master and infor record calender in Enterprise Resource Planning Q&A

- How to reproduce CO16N? in Enterprise Resource Planning Q&A

- The project system should automatically update the equipment usage counter in Enterprise Resource Planning Q&A

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 11 | |

| 10 | |

| 9 | |

| 7 | |

| 7 | |

| 7 | |

| 6 | |

| 5 | |

| 4 | |

| 4 |