- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Refurbishment Process in Plant Maintenance

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

sriram_007

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-16-2023

3:49 AM

REFURBISHMENT PROCESS- PM04

The Process of SAP Refurbishment involves repair of older or damaged equipment or spares with high cost to restore it to workable condition. In any production plant, refurbishing damaged, high quality and repairable material is a core maintenance process.

Refurbishment saves costs over Purchasing new components.

The SAP Refurbishment process is triggered when a equipment breakdown occurs. A breakdown order to replace the damaged equipment is created.

The defective item receives a downgraded valuation type and is replaced and stored in the warehouse.

A refurbishment order is created using the material and serial number combination of the damaged material which is then sent for repair.

Once it is repaired, the equipment or spare is returned to the warehouse with the upgraded valuation type

VALUATION PROCESS:

The spare part has different valuation types to represent different values. Because it is also a high value spare part or critical part, this spare part is serial-number managed.

Serial numbers can be assigned to the procured material. while receiving the material with serial number, equipment will be created automatically in back end for the respective material with serial number. These repairable spare parts can be identified with different cost assignments & valuation types like

INITIAL PROCESS:

If the installed equipment malfunctions, it is dismantled from the functional location and a spare part / Equipment is withdrawn and installed at the functional location due to the un-stoppage of production. The defective equipment is returned as damaged item to the warehouse by marking it as C3 - valuation type. The stock in the warehouse is automatically updated with corresponding cost. The who process of dismantling & moving the faulty equipment to store is done by creating a maintenance order.

Components for replacement

Quantity specified as -1 for the damaged equipment by marking as either C3 or Damaged in the batch field & the same is dismantled from the functional location & moved to store with reference order. The material which is going to replace is marked as C1 or New with quantity 1 in Positive. This will be assigned to the same functional location.

REFURBISHMENT ORDER - IW81:

In the next step, the maintenance planner creates a refurbishment Order, These defective repairable spares (valuation class C3 - Damaged) are withdrawn from the warehouse and repaired. when the refurbishment is finished. The equipment or spare is returned to warehouse as repaired material(valuation type - C2 - Refurbished) and the cost is updated accordingly to the material master.

To carry out the refurbishment for a piece of equipment or spares, you need to link the equipment with a material because refurbishment is done for material & not for an equipment.

In refurbishment order - Refurbishment can be done by internal processing, Sub - Contracting, Service.

Initially the Target Quantity is in 1

In this Control keys are mentioned as PM02

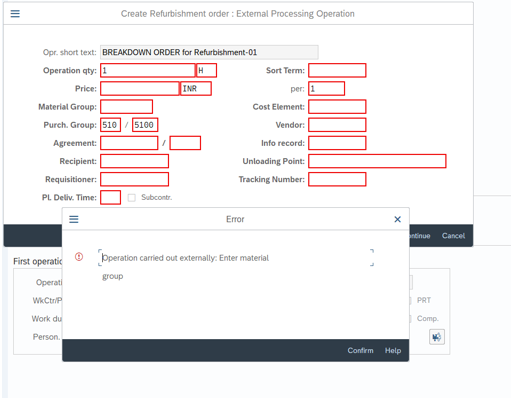

Operation will carried out externally system will ask for the following data,

Fill the relevant Price, Material group, Purchasing group and cost element.

Order was created with the respective entries.

Now Purchase Requisition was created, Go to IW32 and in the Act.Data Tab you'll find the PR.

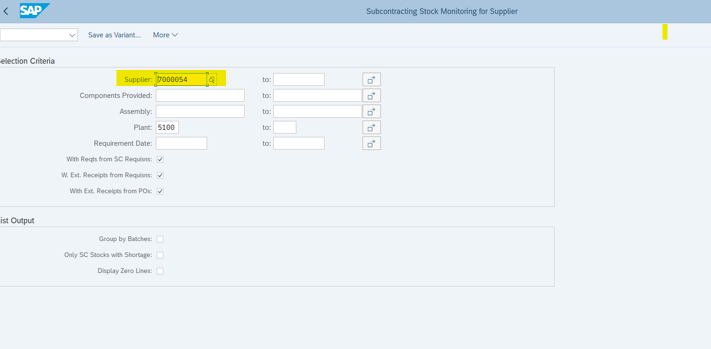

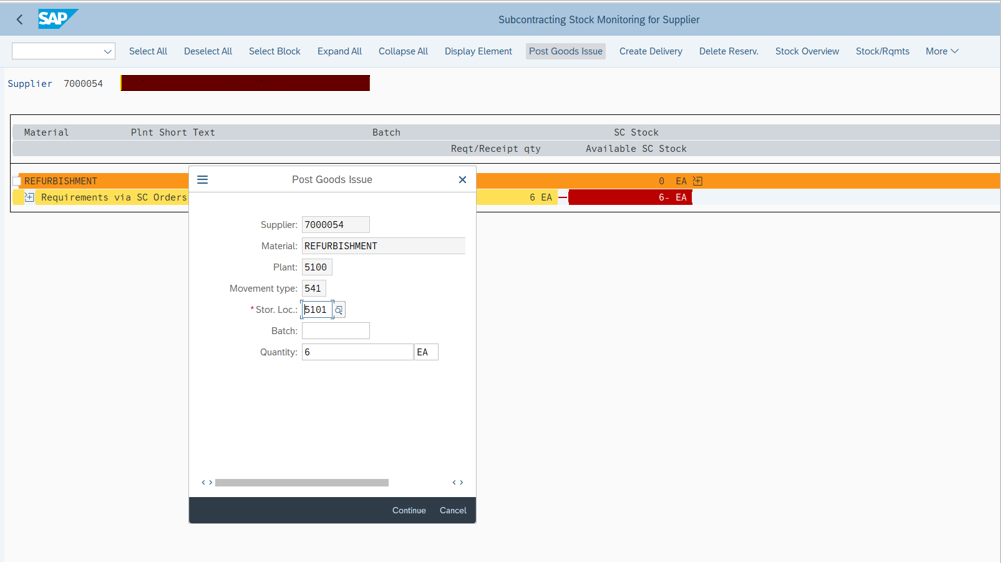

Now, for the Subcontracting Stock Monitoring for supplier in ME2O

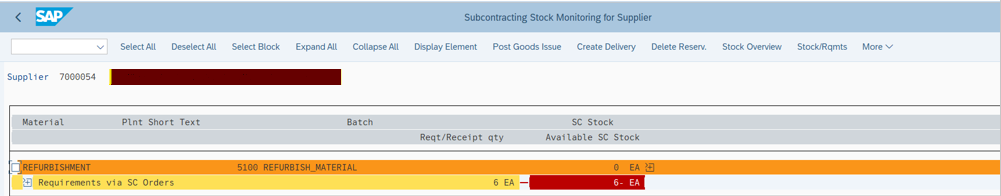

Now After the Purchase Order, Need to send the material to the vendor via PGI - Post Goods Issue

Select the line item and click the Post Goods Issue.

Assign the respective Batch and Quantity.

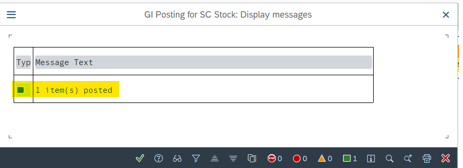

One item got posted via Post Goods Issue.

Now for the Goods movement in MIGO, Fill the all required entities and Post.

Now in the Order level we can see the the Deliver quantity as 1

Now complete the Order.

The Process of SAP Refurbishment involves repair of older or damaged equipment or spares with high cost to restore it to workable condition. In any production plant, refurbishing damaged, high quality and repairable material is a core maintenance process.

Refurbishment saves costs over Purchasing new components.

The SAP Refurbishment process is triggered when a equipment breakdown occurs. A breakdown order to replace the damaged equipment is created.

The defective item receives a downgraded valuation type and is replaced and stored in the warehouse.

A refurbishment order is created using the material and serial number combination of the damaged material which is then sent for repair.

Once it is repaired, the equipment or spare is returned to the warehouse with the upgraded valuation type

VALUATION PROCESS:

The spare part has different valuation types to represent different values. Because it is also a high value spare part or critical part, this spare part is serial-number managed.

Serial numbers can be assigned to the procured material. while receiving the material with serial number, equipment will be created automatically in back end for the respective material with serial number. These repairable spare parts can be identified with different cost assignments & valuation types like

- NEW (C1)

- REFURBISHED(C2)

- DEFECTED or DAMAGED(C3)

INITIAL PROCESS:

If the installed equipment malfunctions, it is dismantled from the functional location and a spare part / Equipment is withdrawn and installed at the functional location due to the un-stoppage of production. The defective equipment is returned as damaged item to the warehouse by marking it as C3 - valuation type. The stock in the warehouse is automatically updated with corresponding cost. The who process of dismantling & moving the faulty equipment to store is done by creating a maintenance order.

Components for replacement

Quantity specified as -1 for the damaged equipment by marking as either C3 or Damaged in the batch field & the same is dismantled from the functional location & moved to store with reference order. The material which is going to replace is marked as C1 or New with quantity 1 in Positive. This will be assigned to the same functional location.

REFURBISHMENT ORDER - IW81:

In the next step, the maintenance planner creates a refurbishment Order, These defective repairable spares (valuation class C3 - Damaged) are withdrawn from the warehouse and repaired. when the refurbishment is finished. The equipment or spare is returned to warehouse as repaired material(valuation type - C2 - Refurbished) and the cost is updated accordingly to the material master.

To carry out the refurbishment for a piece of equipment or spares, you need to link the equipment with a material because refurbishment is done for material & not for an equipment.

In refurbishment order - Refurbishment can be done by internal processing, Sub - Contracting, Service.

Initially the Target Quantity is in 1

In this Control keys are mentioned as PM02

Operation will carried out externally system will ask for the following data,

Fill the relevant Price, Material group, Purchasing group and cost element.

Order was created with the respective entries.

Now Purchase Requisition was created, Go to IW32 and in the Act.Data Tab you'll find the PR.

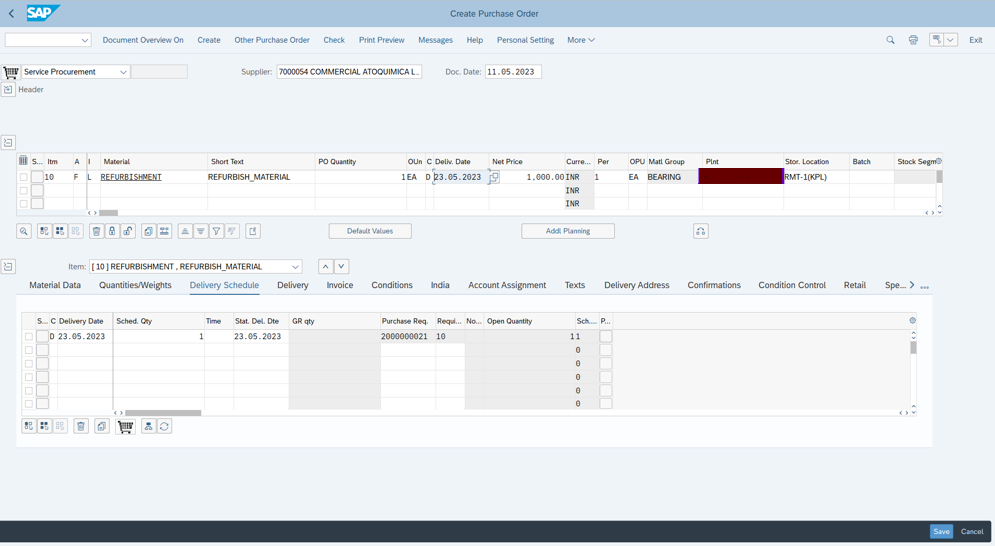

Now for the Relevant PR, Next to do the Purchase Order,

Now, for the Subcontracting Stock Monitoring for supplier in ME2O

Now After the Purchase Order, Need to send the material to the vendor via PGI - Post Goods Issue

Select the line item and click the Post Goods Issue.

Assign the respective Batch and Quantity.

One item got posted via Post Goods Issue.

Now for the Goods movement in MIGO, Fill the all required entities and Post.

Now in the Order level we can see the the Deliver quantity as 1

Now complete the Order.

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Equipment/Functional location Manufacturer Serial number --> Order --> PR in Enterprise Resource Planning Q&A

- Proactive Order (YA02) is not generating with Notifiction type (Y2) and giving error while schedulin in Enterprise Resource Planning Q&A

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Maintenance Order Components - PR should create with Equipment serial numbers. in Enterprise Resource Planning Q&A

- Account Balance Validation in SAP S/4HANA Cloud, Public Edition in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |