- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Q&A

- Capacity Planning not working (Process industry)

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Capacity Planning not working (Process industry)

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-14-2017 7:50 PM - edited 02-04-2024 2:24 AM

Hello Experts,

I have tried almost everything in my knowledge and available on scn but capacity planning is not working. When I create process order capacity requirements are not generated it says "No reqmts/caps exists or not relevant to finite scheduling", although "scheduling carried out" green tick appears bottom of screen. When I Goto logs->For scheduling, it says "Scheduling log does not contain any entries".

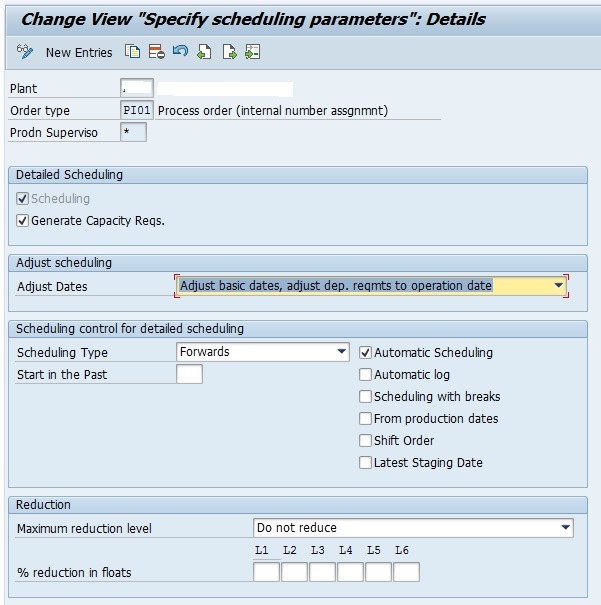

I have done multiple settings and tests in CORY, OPUZ, OPU5 but no luck.

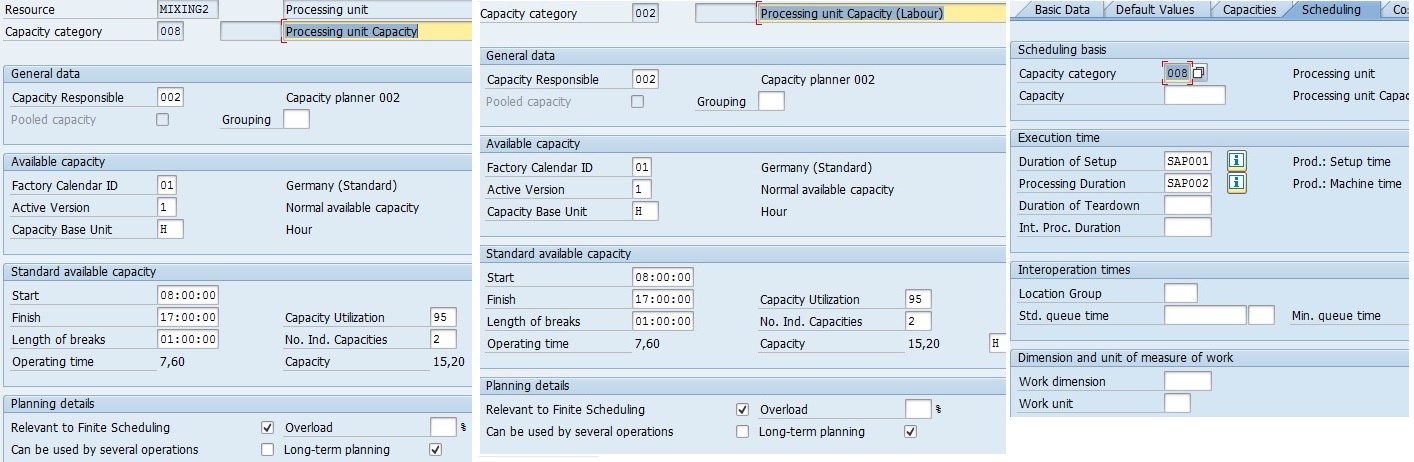

Resource capacity is relevant to finite scheduling and Capacity header data is also maintained.

Also when I do Scheduling in master recipe in C202 all dates (earlier start ,latest start,earlier finish,latest finish ) are same and time is also 00:00:00.

I think it's master data but i have also checked it multiple times with different combination and still no luck. I have even maintained scheduling profile PI01 in work scheduling view.

Kindly help.

BR,

Shankar

- SAP Managed Tags:

- MAN (Manufacturing),

- MAN Material Requirements Planning,

- MAN Production Planning (PP)

Accepted Solutions (0)

Answers (4)

Answers (4)

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Formulas are configured in OPCY. Notice, "Generate" and "work center for capacity requirement" must be ticked ON for capacity calculation.

Parameters of formula are configured in OPCX.

KBA 2584494 - Scheduling in Process Order describes scheduling formulas, capacity formulas are similarly, but maintained in Capacity tab of resource.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Dear Shankar,

As advised by Caetano Almeida I believe the issue is related to the Formula managed in the Scheduling View and Capacity View at the work center level. I believe you are trying to accomdate Setup time/Processing Time etc. in your process order just as we expect it in the Production Order.

For the Scheduling and Capacity Formula in process industry should be managed at Other Formula section. If you want to Include the Setup time and processing time, then have a Formula like (e.g.) setup time + Processing time * Operation qty/Base Quantity and assign it to the Other Formula section.

This should help you out with the Correct Scheduling/Capacity. Do check and let us know.

Regards,

Krishnan.S

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello Shankar,

Sorry on the late reply. The standard Formula is SAPC000.But you can create your own required formulas (E.g. Setup time + Processing time * Operation Quantity/Base Quantity) and assign it to the other Formula section of the Capacity tab.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello

There are many possible causes for this issue.

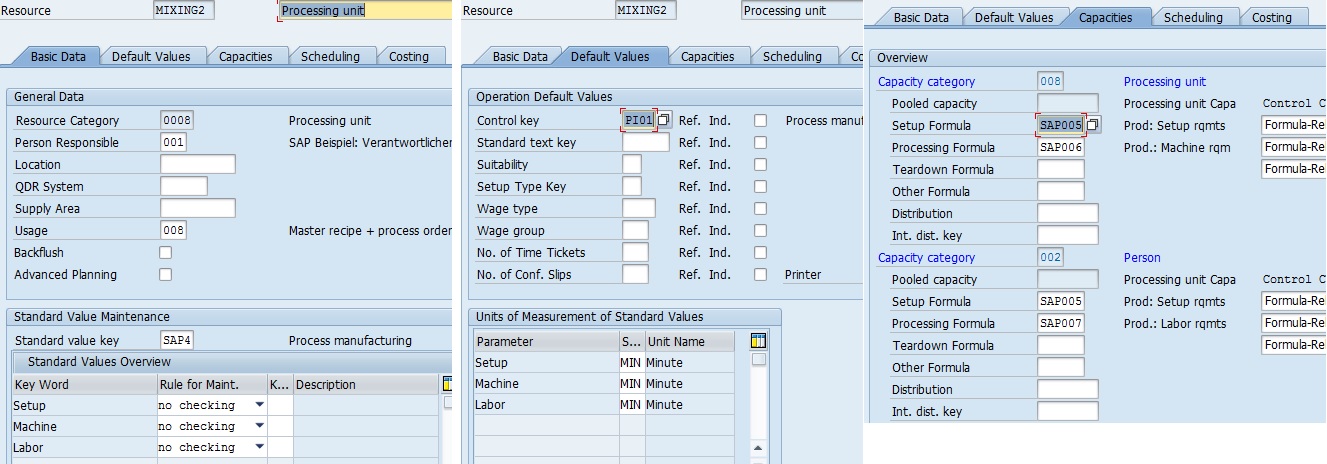

I would first review your resource settings. You should observe that the process order resource uses different formulas, as the scheduling is based in the duration instead of setup + processing.

Make sure that you are using a standard value key proper for process manufacturing (such as SAP4) and make sure that you are using a proper formula (such as SAPC00).

Also, in OPUZ, make sure that you are using a routing selection ID that considers master recipe and that you have a valid master recipe and a production version for your material.

Regards,

Caetano

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello Caetano,

Thankyou for your reply, I have attached screen shots of OPUZ and Resource tabs:

OPUZ:

CRC2 Resource Tabs:

CRC2 Resource Tabs:

Can you please guide me which Formulas to use for Capacity category 008 and Capacity category 002. Also kindly guide which formulas to use with regard to Capacity category for CAPACITY tab and which for SCHEDULING tab.

I can't find many formulas in standard system.

BR,

Shankar

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

I believe you did not maintain shift sequence for the work center. Click on 'Intervals & Shifts' from transaction CR02 to respective work center and update the shifts timings accordingly.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Why YCOA? The value of the standard Chart of Accounts in S/4HANA Cloud Public Edition. in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Manufacturing in Enterprise Resource Planning Blogs by SAP

- Intercompany Execution of Services (aka "Dual Order") in Enterprise Resource Planning Blogs by SAP

- Manage work center capacity for maintenance order in Enterprise Resource Planning Q&A

- Machines grouping in work centers for Textile Industry in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 99 | |

| 9 | |

| 9 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.