- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Q&A

- EWM fixed bin + capacity check during putaway

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

EWM fixed bin + capacity check during putaway

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 04-18-2023 8:04 PM

Hi experts,

My customer is willing to maintain fixed bins for his products, with bin assignment through /SCWM/BINMAT, but WITHOUT maintaining related storage type view data for all his products in /SCWM/MAT1.

All fixed bins are physically the same, in one storage type.

In addition, during goods inward, after HU creation and GR, target is to fill fixed bin with the first HU(s), as long as there is enough room in the fixed bin during the WT creation.

My issue is that so far, without maintaining max. qty in /SCWM/MAT1, only replenishment works fine, any putaway of multiple HUs for the same product are leaded to the fixed bin, regardless of current stock situation in it.

I've tried processing multiple HU putaway into empty fixed bins with

- Capacity check according to product Key figure + UOM capacity usage in products + capacity in fixed bin

Not working, even though my HU have accurate capacity usage and bins are defined with accurate capacity allowance, when I process the putaway of x HU, first one is directed in my empty fixed bin, but next pallets are also directed to the fixed bin, and the WT creation log shows a capacity check not updated from previous pallet WT.

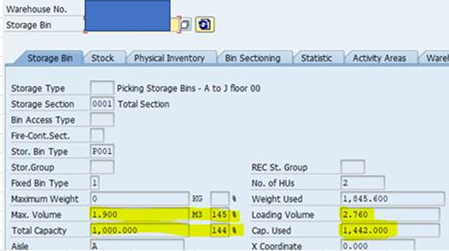

The capacity is updated though, but after the WT creation, showing me as a result a capacity usage of 200% or more in /SCWM/LS03

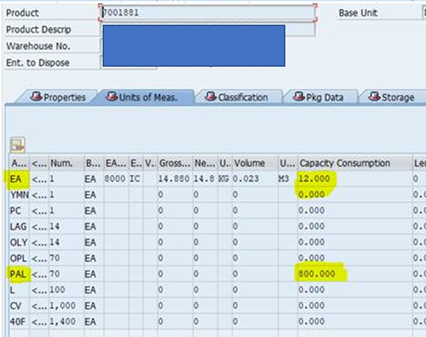

Capacity data from product UOM:

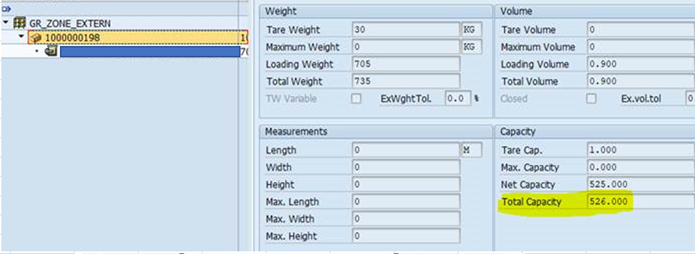

Capacity usage from one HU created during IBD process

Result after processing WT creation of 2 Hus

- Limitation of weight /volume --> seems that this is not checked at all, and allow putaway raising overcapacity into the fixed bin

So, if I get it right, in order to fill the requirement, looks like I have not many choices:

- Maintain /SCWM/MAT1 with a maximum quantity per product

- Change my setting so that my fixed bin storage type won’t allow additional to stock and segregate putaway to 1 bin max, but that would influence my replenishment process and will lead to replenishing only when bin is fully depleted

- Use BADI to play with capacity check myself during WO creation

Did I miss something, or capacity is not checked during putaway into fixed bins by SAP standard ?

Accepted Solutions (0)

Answers (4)

Answers (4)

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi davidak

Please use below BADI.

Text copied from OSS-2859516

This is the correct EWM standard behaviour. In the EWM standard design the entries in /SCWM/BINMAT are planning values for the replenishment only.

It is not intended to use the maximum quantity from /SCWM/BINMAT during the putaway.

Resolution

There is a check on the 'Maximum Storage Type Quantity' that can be activated in the customizing, but it relies on the maximum quantity value from the product master data (/SCWM/MAT1) in the storage type view.

To fulfill this requirement you either have to set up the capacity check (so that each bin can only hold one HU), or you have to implement the BAdIs in enhancement spot /SCWM/ES_CORE_PTS (e.g. BAdI /SCWM/EX_CORE_PTS_CAPACHECK, /SCWM/EX_CORE_PTS_FILT_SORT or /SCWM/EX_CORE_PTS_NBIN_NRM).

Details:

https://me.sap.com/notes/2859516/E

Kind Regards,

Ajit

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi David, did you solve this problem??

I'm facing the same issue.

Regards

KSM

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Thanks for the update Jürgen.

i've checked it with capacity ccheck set to 2 and 3.

But i will have to check if there is any Badi or enhancement running that could mess up with it. According to what you Say that's most probably the case.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi,

"Did I miss something, or capacity is not checked during putaway into fixed bins by SAP standard ?"

Yeah, you are either missing something or something is setup wrong. Because I show this scenario practically every week, and it works, just by using weight.

"My issue is that so far, without maintaining max. qty in /SCWM/MAT1, only replenishment works fine"

For calculating the replenishment quantities, you will need this. I am not even sure if the maximum quantity is considered for anything else then replenishment (but I muss confess that I still haven't tried this).

"Limitation of weight /volume --> seems that this is not checked at all, and allow putaway raising overcapacity into the fixed bin"

This is checked. As long as you do not deactivate it in the storage type (with capacity check "4 - no check according to weight, volume, key figure").

Did you check if the flag "no capacity update" is set eventually in the storage type? Because then no update is done (but I think that it would not show what you have in your screenshots).

I would recommend to create some warehouse tasks and to carefully check the log during the creation, that will show what checks are done.

Brgds

Juergen

---

All the above is no official SAP statement.

Want to learn EWM?

Check for EWM courses: https://training.sap.com/trainingpath/Applications-Extended+Warehouse+Management-EWM+in+S4HANA

Get a SAP Learning Hub Subscription: https://training.sap.com/learninghub

And it is EWM. NOT eWM - Duh!

And if your question includes the word "transfer order" - do NOT tag the question with Extended Warehouse Management!

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- EWM POSC RF Repack in Supply Chain Management Q&A

- Setup Time Optimizer query (Non-PPDS) in Supply Chain Management Q&A

- TOP 3 future trends to watch in data analysis in Supply Chain Management Blogs by Members

- New features in SAP Warehouse Operator Version 2.3 in Supply Chain Management Blogs by SAP

- SAP EWM Addition to stock putaway strategy in Supply Chain Management Q&A

| User | Count |

|---|---|

| 12 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.