- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Q&A

- Substitution fails...in RBA

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Substitution fails...in RBA

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 11-30-2016 6:37 PM

Hello,

I am running into a problem in Rule Based ATP.

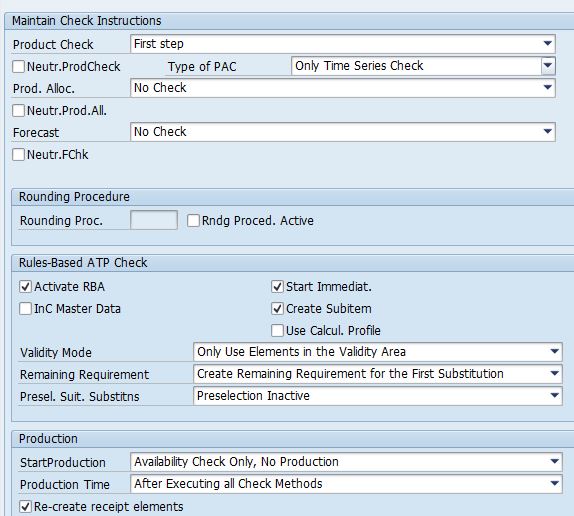

In our Check instructions for Rule based ATP Check, I have selected 'Create Remaining Requirement for Source Location product'. My assumption was this:

1. Material A Req Qty 200

2. Material A Stock 100

3. Material B Stock 50(We can substitute this for Material A)

4. With the above setting I thought I would be able to create a planned order for Material A(we have CTP running) for 50. Unfortunately the system ignores Material B completely and creates a Planned order for Material A for 100. Flabbergasted.

If this is how it is going to work, then there will never be a substitution. Am I missing something?

Thanks in advance,

Subash Nanjangud

- SAP Managed Tags:

- SCM APO Global ATP

Accepted Solutions (0)

Answers (4)

Answers (4)

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Thanks Mohit...I will try that. What release are you on? My screenshot above looks different from yours but the same functionality.

Subash

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Thanks Monitor,

I will get back to you on this.

Subash

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Substitution and report for tasks included in checklists (OJT) in Supply Chain Management Q&A

- Location Product Substitution in Supply Chain Management Q&A

- Attach Rate Planning in IBP in Supply Chain Management Blogs by Members

- SAP S/4HANA 2023 FPS1: TM master data based Sales Order Scheduling in Supply Chain Management Blogs by SAP

- S/4 HANA Advanced available to promise Location Substitution Configurations steps. in Supply Chain Management Blogs by Members

| User | Count |

|---|---|

| 9 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.