- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Q&A

- Stock removal rule doesn't work as expected

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Stock removal rule doesn't work as expected

- Subscribe to RSS Feed

- Mark Question as New

- Mark Question as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

on 06-14-2022 12:26 PM

Hello everyone,

this is my first time on this forum and i already tried to find a solution for my problem but i found nothing.

The situation is as follows.

I specified a stock removal rule called FIFO like this.

VFDAT = Shelf Life Expiration Date

WDATU_DATE = Goods Receipt Date

Quan = Available Quantity

All of them ascending. The VFDAT doesn't matter most of the time. It's just there for paint that came back from the production and therefore got a new Goods Receipt Date in the EWM.

I made sure that the goods removal strategy im using is using this stock removal rule.

I would expect that the system looks for the oldest stock first and then looks for the storage bin with the lowest available quantity. The goal in this case is to free up almost empty bulk storage first before anything else.

In my test case i have an outbound delivery asking for 336 peaces of a product. That equates to 7 full Handling Units.

I have available stock on two storage bins. Bin A and BIN B.

On BIN A there are 384 peaces or 8 full handling units. Enough for the delivery.

On BIN B there are 624 peaces.

The entire stock on bin A has the Goods Receipt Date 2021/11/10.

On bin B the Goods Receipt Dates are 2021/11/10 (8 HU) and 2021/12/10(5 HU).

With all these informations i would expect the system to pick the stock from Bin A. There is enough stock with the oldest Goods Receipt date available and the lowest available quantity. But it doesn't. It picks the stock from Bin B.

I don't understand why this happens and what i did wrong. Maybe my understanding of the stock removal rule isn't correct.

I really appreciate any advice in this matter.

Thanks in advance.

Greetings Tobias

Accepted Solutions (1)

Accepted Solutions (1)

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi,

ok, so coming back to the original question 😉

tmarkus

"With all these informations i would expect the system to pick the stock from Bin A. There is enough stock with the oldest Goods Receipt date available and the lowest available quantity. But it doesn't. It picks the stock from Bin B."

All the sort fields in your pick rule refer to the quant (how should it otherwise work when you have mixed storage, like in your case, and sort by GR date?). So the sorting by QUAN doesn't necessarily consider the quantity in the bin, but the quantity of the individual quant. This is probably influenced by you setting in the storage type with regards to level of available quantity, I would need to check this.

AFAIK the next sorting (when all the information is the same) would be the GUID of the quant (which is an unreadable string).

Brgds

Juergen

---

All the above is no official SAP statement.

Want to learn EWM?

Check for EWM courses: https://training.sap.com/trainingpath/Applications-Extended+Warehouse+Management-EWM+in+S4HANA

Get a SAP Learning Hub Subscription: https://training.sap.com/learninghub

And it is EWM. NOT eWM - Duh!

And if your question includes the word "transfer order" - do NOT tag the question with Extended Warehouse Management!

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Good Morning Jürgen,

thank you very much for you explanation.

So my understanding of the stock removal rule was actually wrong. 😄

So is there any way i could achive my goal of freeing almost empty bulk storage

bins first? Besides of developing a program which helps me with that. 😄

It would help my collegues in the warehouse a lot so they have to do less

internal rearangement between the storage bins to empty them and make space for

new handling units with different products.

Greetings Tobias

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi,

"So is there any way i could achive my goal of freeing almost empty bulk storage bins first?"

OK, in that case I want to test this. Because in a bulk storage storage type the available quantity is on bin level. So if you sort by QUAN ascending (as the "descending" flag is not set), yes, I would also expect that the bin A is used first. But again I am not sure how in such a case the GR date is used. You know that one special behaviour of bulk storage is that the system does not propose which HU to pick. This is because the system does not know where the individual HU is and we do not want the picker to remove half or more of the HUs in order to reach the correct one.

Brgds

Juergen

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello Jürgen,

"You know that one special behaviour of bulk storage is that the system does not propose which HU to pick. This is because the system does not know where the individual HU is and we do not want the picker to remove half or more of the HUs in order to reach the correct one."

Yes i am aware of that.

Would suggest for me try to create a new stock removal rule with just the QUAN and see if that works? In this specific storage the emptiest bin is usually also the bin with the oldest stock. So this might work. I'll give it a try and keep you updated.

Greetings Tobias

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hi Tobias,

ok, I have tested this scenario (except that I did not use VFDAT, but you wrote that it would not matter in that moment) - but I say the scenario should work.

I have two bins, one (0040-A) is full with 12 HUs, the other (0040-B) has 2 HUs only. When I sort only by GR date, the bin A is taken. If I additionally sort by QUAN, then bin B is used. I see no problem.

"On bin B the Goods Receipt Dates are 2021/11/10 (8 HU) and 2021/12/10(5 HU)."

For you bulk storage this does not matter, you do not have two GR dates. Because the available quantity is kept on bin level, you have a quantity of 624 pieces and only ONE GR date. Which date this is, is controlled by your settings in the storage type, the field "Mix GR Dates". The standard entry is allowed - most recent date dominant. But that seems NOT to be the case in your example, because that would mean that the GR date is 2021/12/10 (that is year/month/date? Well, also do not really matter). So anyway the bin A of your example should be selected, as this has the older GR date.

I would recommend the following: check the table /SCWM/AQUA in SE16N for you product and that storage type. In the table sort the entries with the sort criteria of your picking strategy, then you see what the system should find. The next step would be to debug the WT creation to see what else might influence this.

Brgds

Juergen

Answers (5)

Answers (5)

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

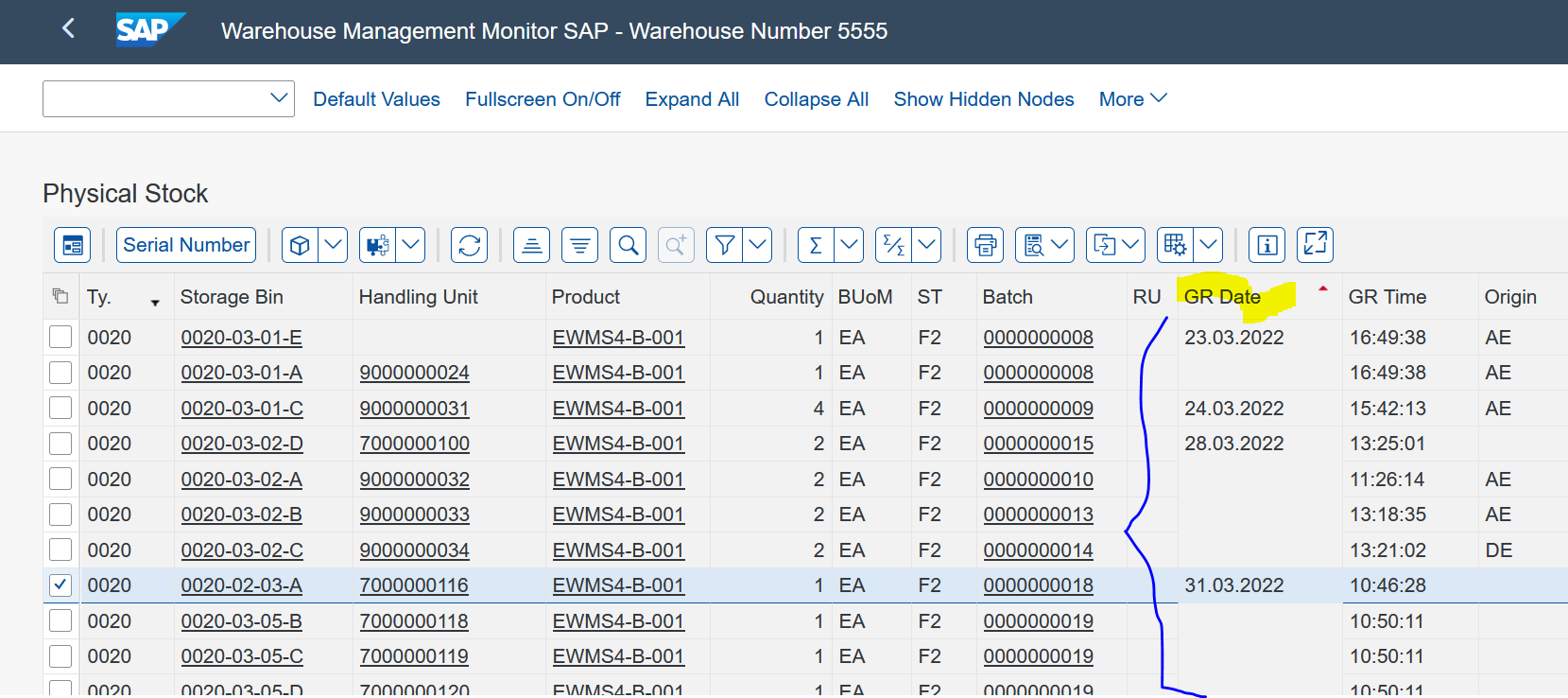

"Stock is picked from the bin 0020-02-03-A although bin 0020-03-01-E has the oldest stock. I am using only FIFO here ."

If this happens - I would clearly say the system has a bug and does not work correctly. If you sort your quants by GR date and the system does not use the oldest quant, something is seriously wrong.

And any sort sequence of the bins should not be used, the only sort field available there is the bin itself and the sort sequence for CLSP (for whatever reason).

In this example the product is batch managed - what are the batch selection criteria?

"With all these informations i would expect the system to pick the stock from Bin A. There is enough stock with the oldest Goods Receipt date available and the lowest available quantity. But it doesn't. It picks the stock from Bin B."

All the sort fields in your pick rule refer to the quant. So the sorting by QUAN does necessarily consider the quantity in the bin, but the quantity of the individual quant. This is probably influenced by you setting in the storage type with regards to level of available quantity, I would need to check this.

Brgds

Juergen

---

All the above is no official SAP statement.

Want to learn EWM?

Check for EWM courses: https://training.sap.com/trainingpath/Applications-Extended+Warehouse+Management-EWM+in+S4HANA

Get a SAP Learning Hub Subscription: https://training.sap.com/learninghub

And it is EWM. NOT eWM - Duh!

And if your question includes the word "transfer order" - do NOT tag the question with Extended Warehouse Management!

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello Juergen and Daniil

Thanks for your feedback and advices.

It is clear to me now. I was able to find out the reason why FIFO didn't work for me.

We got country of origin as space in ODO . We have batches with both COO space and non-space in the EWM stock.

Thanks again and have a nice day.

It was good learning for me.

Regards

ASLAM

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

as Jürgen said maybe it is because of the batch (your product is batch managed) and you could have exact batch or batch selection criteria in your request document (ODO). Sorting should not affect quant sorting (if it is not something like PIPA) .

Hello Daniil

I don't have setup any batch selection criteria , and there is no batch coming from S4 CORE in ODO.

Batch determination/quant is done completely in EWM.

Available stock

WT in simulate mode

I tested even for non batch part.

For me, system is actually considering sort sequence of the bins as well .

Don't know why but it is behaving like that.

see below test

Please guess more 🙂

I am confused now.

Regards

ASLAM

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

hello Juergen

Thanks for your feedback to this.

If this happens - I would clearly say the system has a bug and does not work correctly. If you sort your quants by GR date and the system does not use the oldest quant, something is seriously wrong.

I am just using FIFO with no development or enhancement to SAP standard.

storage type setting

What else do I need to check to have the FIFO ? I am not using any WOCR as well.

Do I need to not sort the bins for PICK activity ?

Regards

ASLAM

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

as Jürgen said maybe it is because of the batch (your product is batch managed) and you could have exact batch or batch selection criteria in your request document (ODO). Sorting should not affect quant sorting (if it is not something like PIPA) .

Other option I see, you have physical stock maybe there no available stock in other bins because of other WT's.

This is just not correct behaviour, hard to guess why without touching the system 🙂

Regards,

Daniil

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

Hello

I hope, you will understand the issue/system behavior after seeing my case below

Stock situation- sorted by GR date ascending

Stock is picked from the bin 0020-02-03-A although bin 0020-03-01-E has the oldest stock. I am using only FIFO here .

Proposed bin by the system while creating WT for ODO

why?

System also takes bin sorting into consideration while stock removal process. Just check if you have done bin sorting for PICK activity in /SCWM/SBST and how does bin sorting looks in table /SCWM/LAGPS

I hope you will be having a better understating now.

Regards

ASLAM

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Report Inappropriate Content

- Highlights of Transportation Management in SAP S/4HANA Cloud Private Edition 2023 (FPS01) in Supply Chain Management Blogs by SAP

- Picking full pallet with multiple Pick-HU's in Supply Chain Management Blogs by Members

- Handy tools for SAP TM Development in Supply Chain Management Blogs by SAP

- Warehouse Management System in Supply Chain Management Blogs by Members

- Is SAP Field Service Management a good fit for utilities to enhance maintenance, metering and service processes? in Supply Chain Management Blogs by Members

| User | Count |

|---|---|

| 9 | |

| 4 | |

| 3 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.